Packaging structure of surface-mount device infrared receiver

A technology of packaging structure and receiving head, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of expensive raw materials, waste of materials, and high prices of mechanical equipment, and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

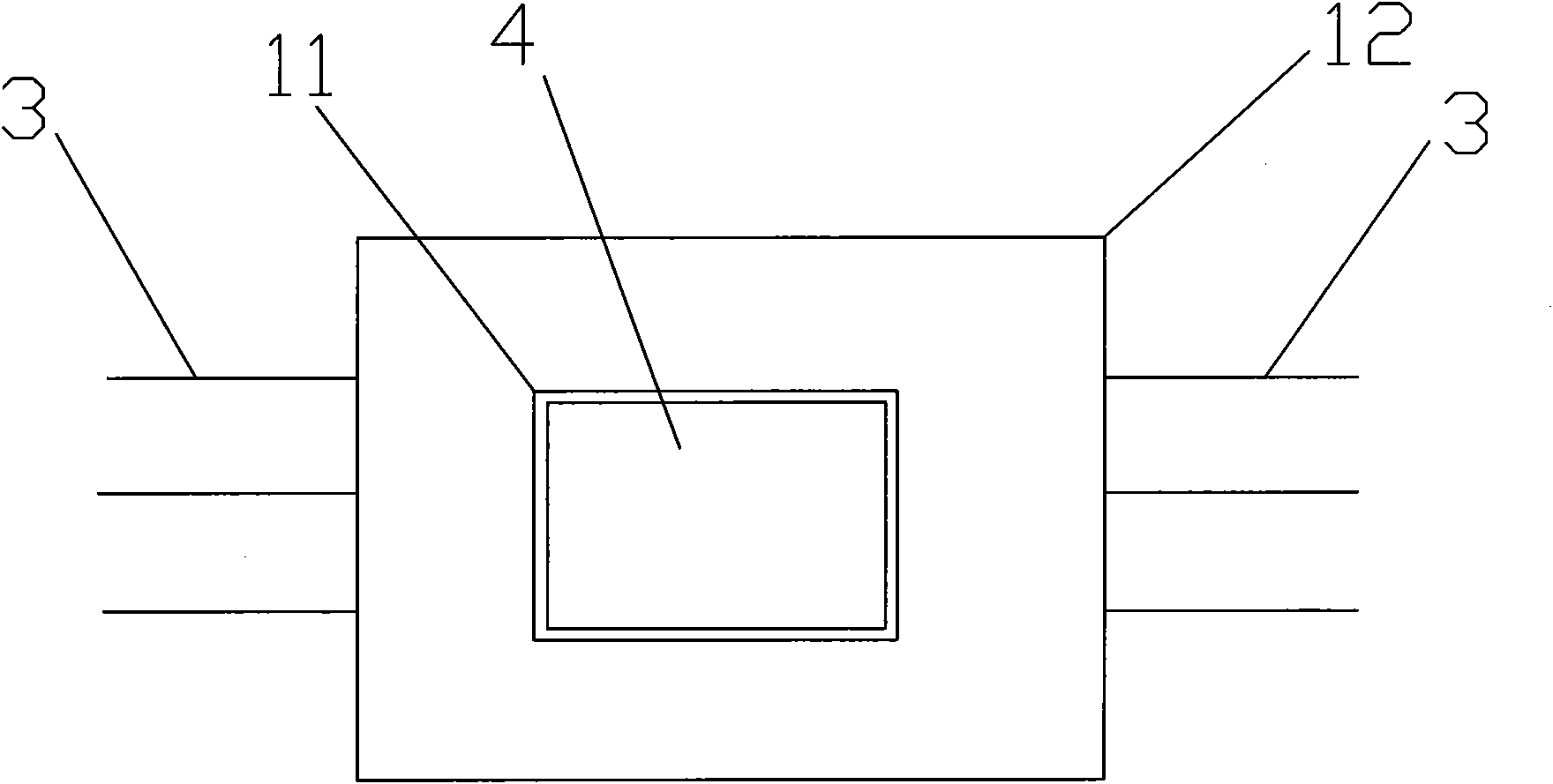

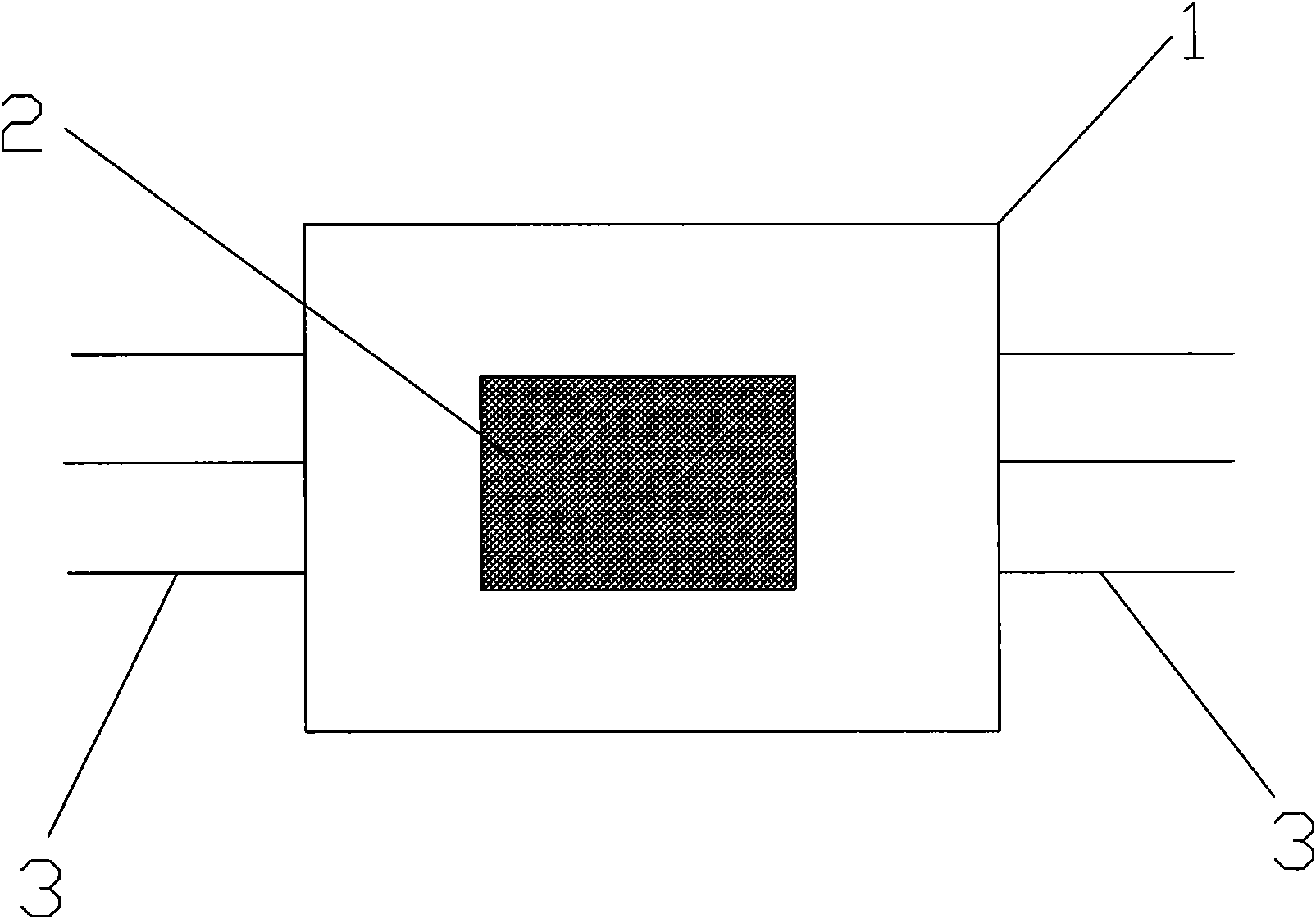

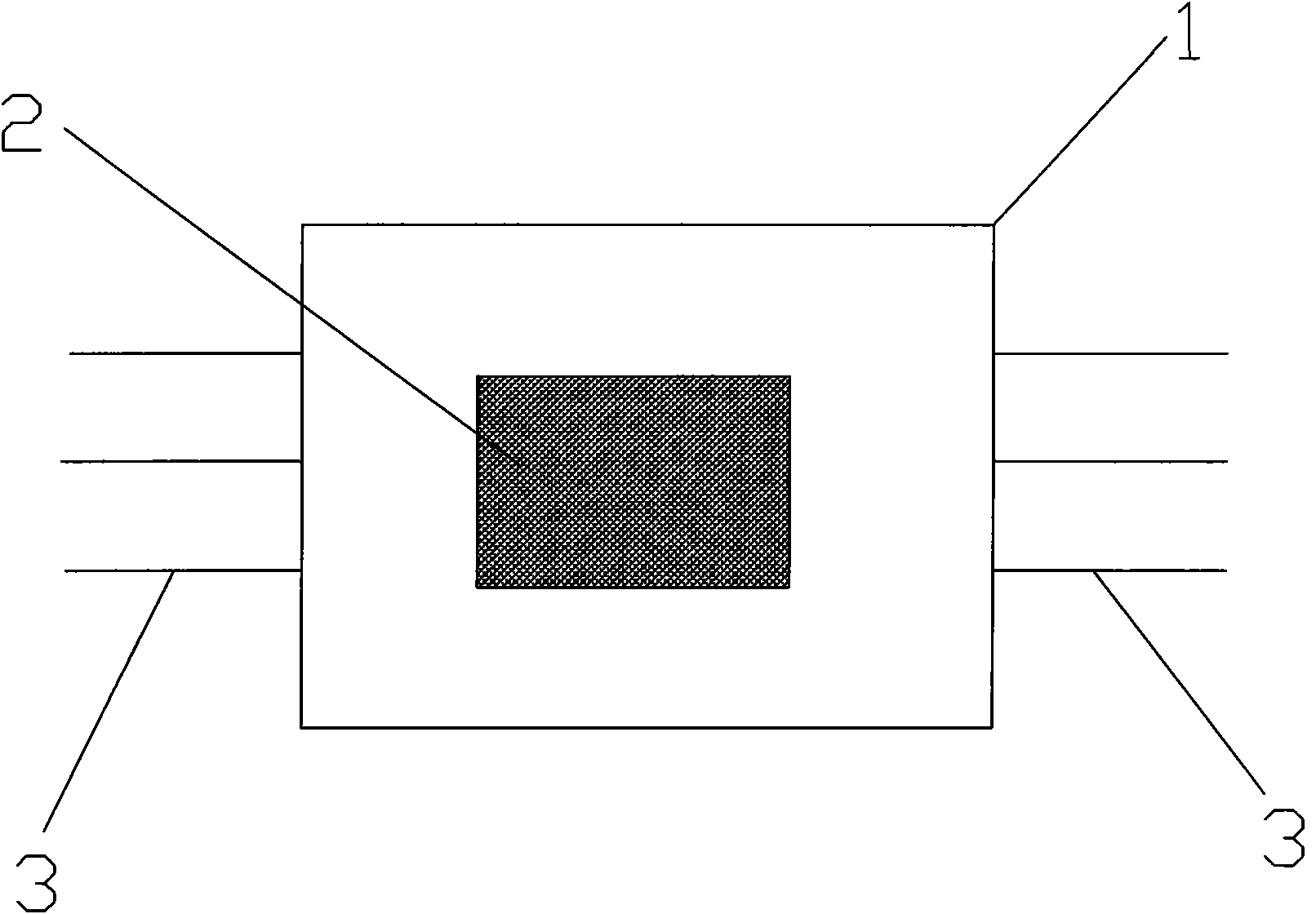

[0012] see Figure 1 to Figure 2 , a packaging structure of an infrared patch receiving head, which is mainly composed of a bracket 1, epoxy resin glue 2, a photosensitive receiving diode (not shown), a signal amplification IC (not shown), and an inner shield (not shown) .

[0013] The bracket 1 is mainly composed of a hardware piece 11 and a frame 12 , the frame 12 is made of high temperature plastic or high temperature resin, and the hardware piece 11 is provided with pins 3 .

[0014] The frame 12 is arranged on the hardware sheet 11 and a photosensitive receiving diode, a signal amplifying IC, and an inner shielding sheet mounting hole 4 are arranged in the frame 12 .

[0015] The photosensitive receiving diode and signal amplifying IC are installed in the installation cavity 4, and the interference of light and electrons to the photosensitive receiving diode and signal amplifying IC is shielded through the inner shielding sheet.

[0016] The signal of the photosensitive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com