Speed reducer

A technology for reducers and gearboxes, which is applied in the direction of mechanical equipment, transmission parts, gear transmissions, etc., can solve the problems of rising device costs, complex overall structure, and unsatisfactory cooling performance, and achieve improved stirring performance and cooling The effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

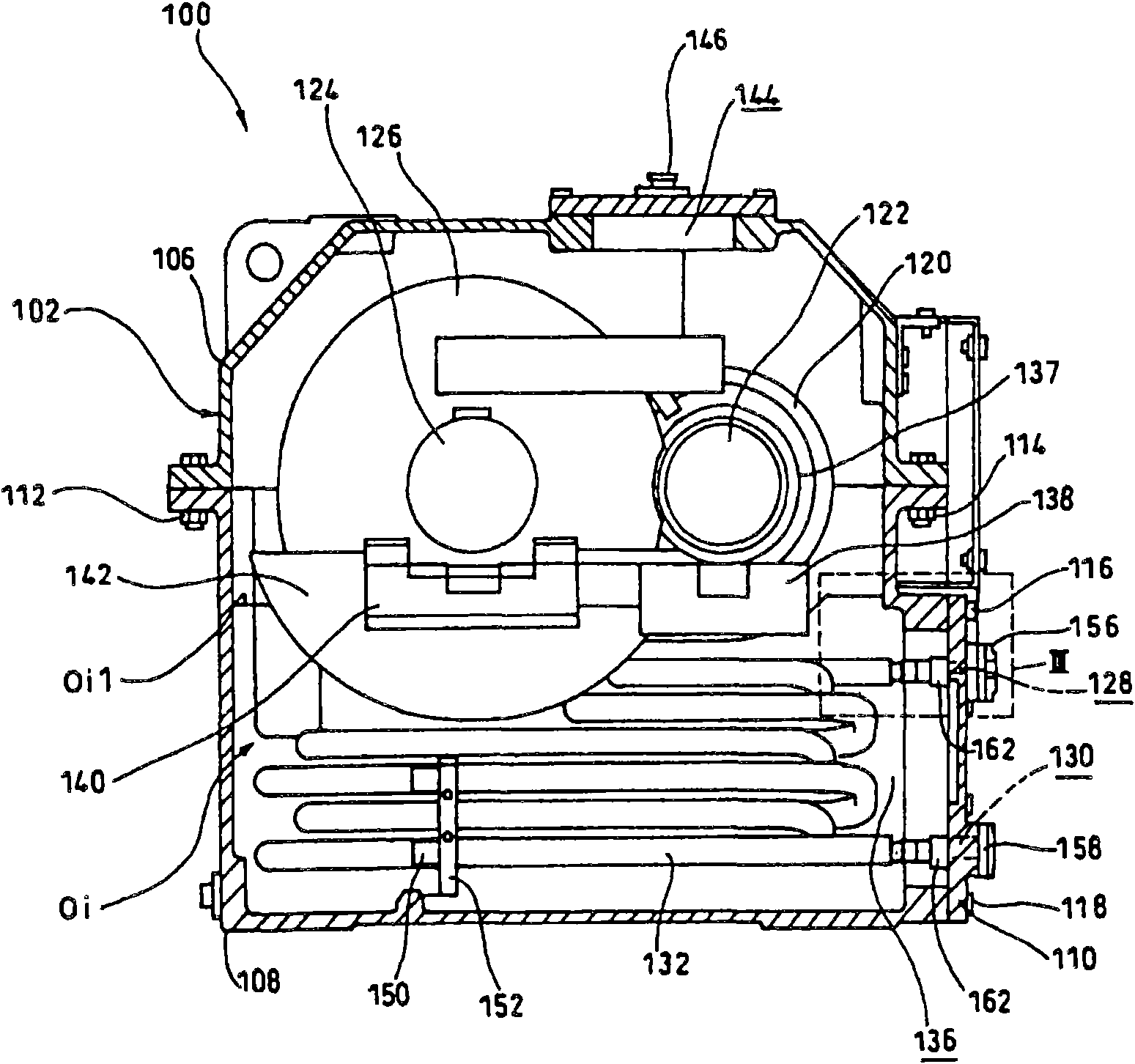

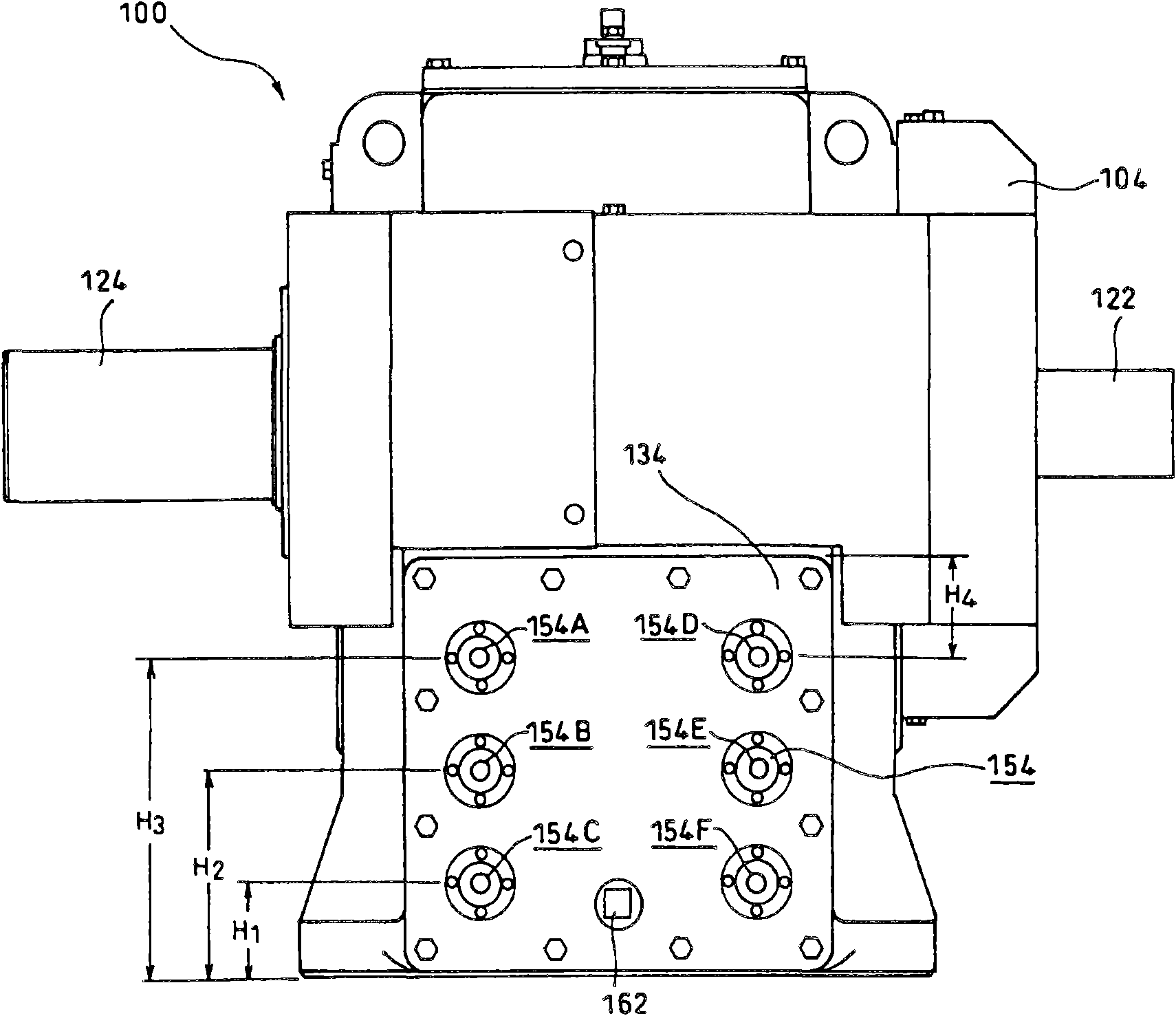

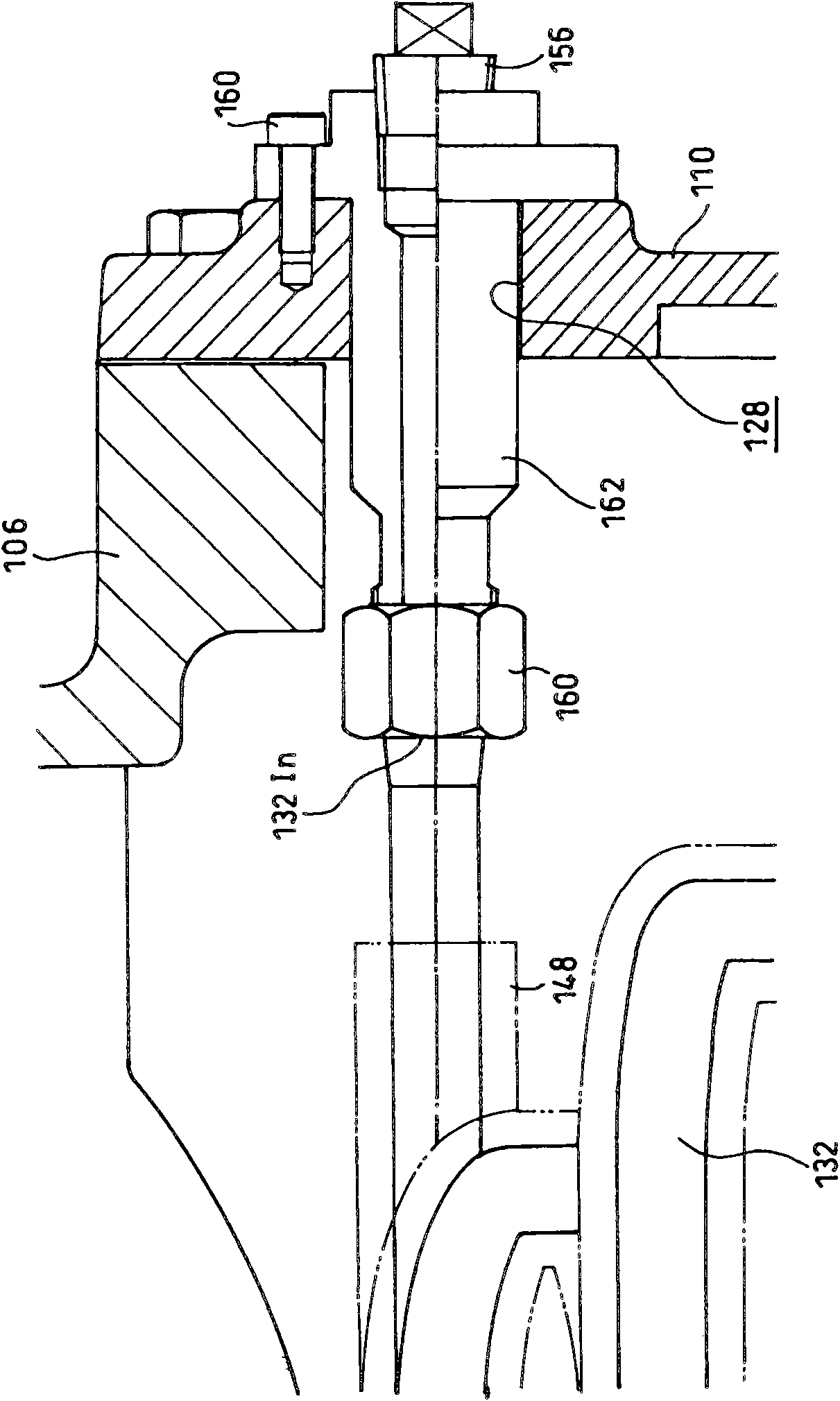

[0024] figure 1 It is a longitudinal cross-sectional view of the reduction gear 100 which concerns on an example of embodiment of this invention. Furthermore, in figure 2 Shows figure 1 A side view of the reducer 100 is shown, in image 3 Shows figure 1 A partial enlarged view of the reducer 100 shown in the direction view III.

[0025] First, the overall structure of the reduction gear 100 will be described.

[0026] The reduction gear 100 includes a gear transmission 102 . The housing 104 of the gear box 102 includes an upper cover 106 , a lower cover 108 and a side cover 110 .

[0027] The upper side cover 106 and the lower side cover 108 are fastened by bolts 112 and 114 . In addition, the lower side cover 108 and the side cover 110 are fastened with bolts 116 and 118 .

[0028] The gear case 102 has a cooling medium introduction hole 128 and an outlet hole 130 on the side surface on the side of the high-speed gear (small-diameter gear) 120 inside the gear case...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com