Process for refining 2-aminoethanesulfonic acid from crude 2-aminoethane-sulfonic acid, 2-aminoethanesulfonic acid obtained there from and use thereof

An aminoethanesulfonic acid, crude technology, applied in chemical instruments and methods, applications, food preparation and other directions, can solve the problems of serious agglomeration, low purity, etc., and achieve the effects of good desalination, high purity, and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

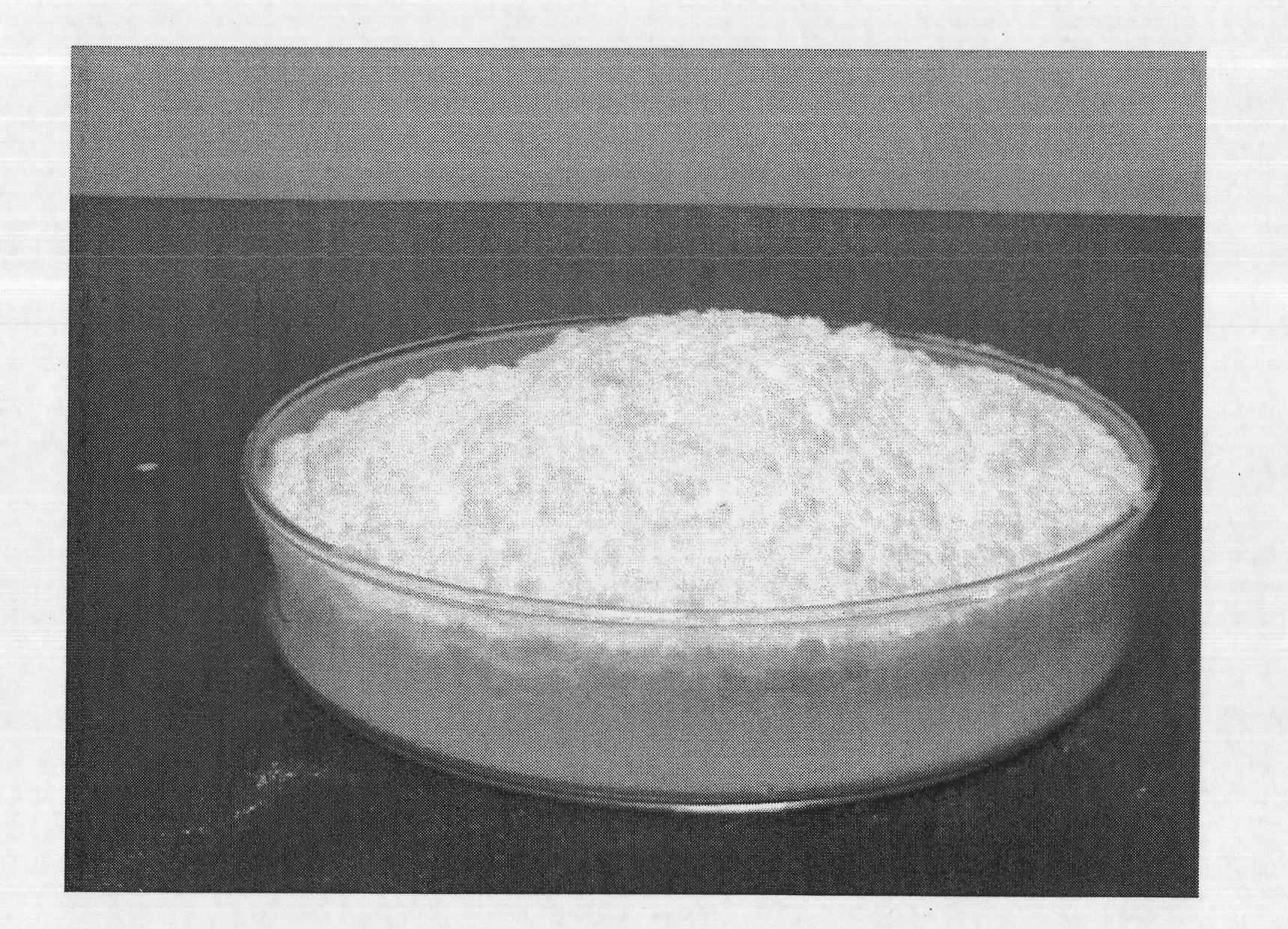

Image

Examples

Embodiment Construction

[0036] The invention will now be illustrated by specific examples. As a comparison, the properties offered by prior art methods are also shown. Comparative example (the method of CN 187,202,917)

[0037] 850kg of 2-aminoethanesulfonic acid (purchased from Hanchuan ShiZhongxin Chemical Product Ltd (Hanchuan ShiZhongxin Chemical Product Ltd), Hanchuan, Fenshui Town, product batch number: PK205-008, taurine content higher than 92%), 2400kg of purified water and 3kg of medicinal activated carbon are placed in an autoclave, heated up to 98°C, then decolorized and pressure filtered to filter out activated carbon and other impurities. The wet product is transferred to the packaging workshop, where the fine crystals are crystallized in an autoclave, cooled to 20°C to 25°C, and then centrifuged in a centrifuge. Wet products with a weight of 500kg containing more than 93% taurine and 3% to 7% water were placed in a GFG high-efficiency boiling drying and sterilizing machine, and dried ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com