Shoulder wedge feeding frame and front guiding and positioning method thereof

A technology of tire shoulder padding and positioning method, which is applied in the field of rubber machinery to achieve the effects of improving the accuracy of edge setting, improving control ability and relieving labor load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

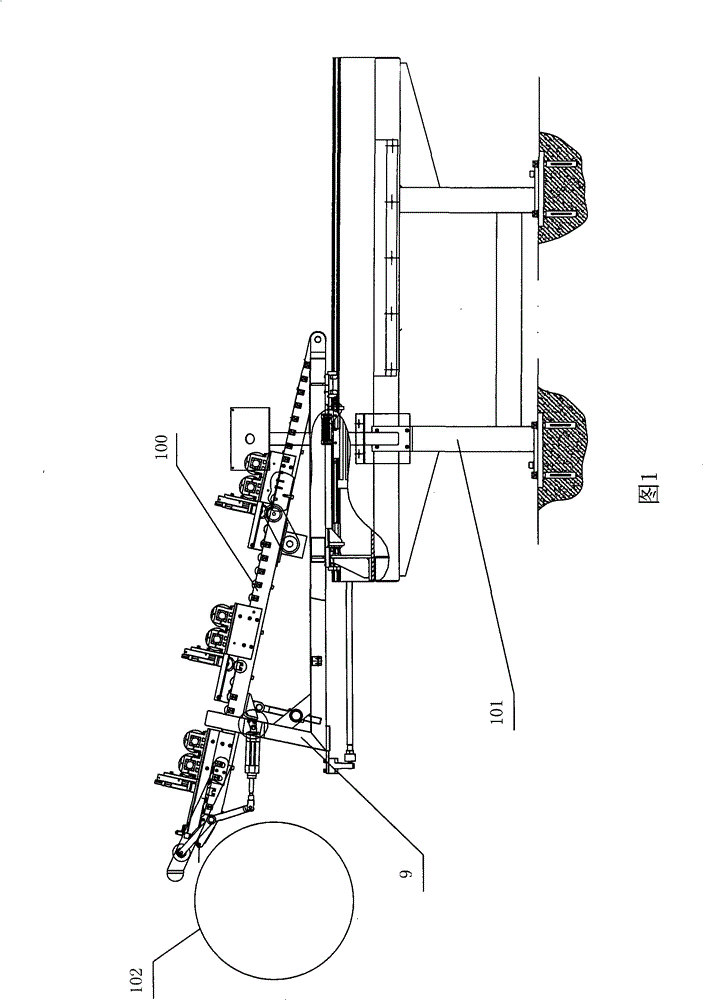

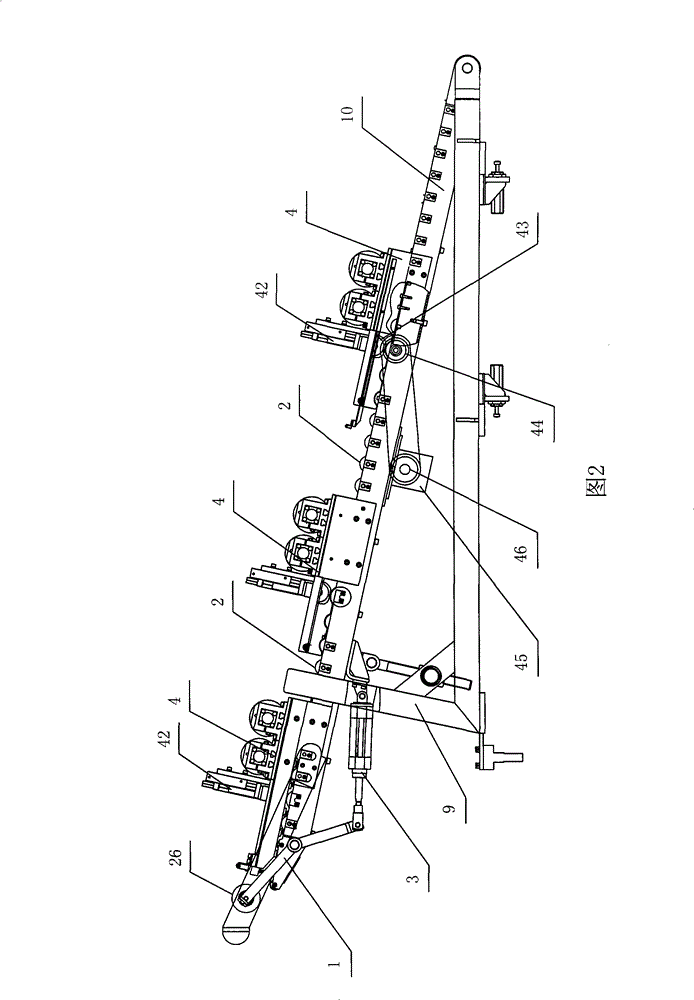

[0055] Example 1, such as Figure 1 to Figure 5 As shown, the shoulder pad rubber supply rack mainly includes a conveying template 100 and a conveying frame 101 . The conveying template 100 is installed on the conveying frame 101 through the supporting frame 9 , and the conveying template 100 is used for conveying the shoulder pad rubber to the building drum 102 .

[0056] The conveying template 100 includes two side supports 10 , and a front pressure roller 26 and a rear guide roller 14 arranged along the conveying direction of the shoulder pad rubber.

[0057] The front end pressing roller 26 is connected to a swing driving cylinder 3 through the swing arm 1 whose shaft is arranged on the support 10 . The front end pressure roller 26 can be driven by the swing driving cylinder 3 to perform vertical reciprocating swing around the middle fixed axis of the swing arm 1 .

[0058] Specifically, when the driving rod of the driving cylinder 3 retracts backward, the swing arm 1 ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com