Electromagnetic water inlet valve

A water inlet valve and electromagnetic technology, applied in the field of electromagnetic valves, can solve the problems of small flow and no water outlet, and achieve the effect of increasing flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

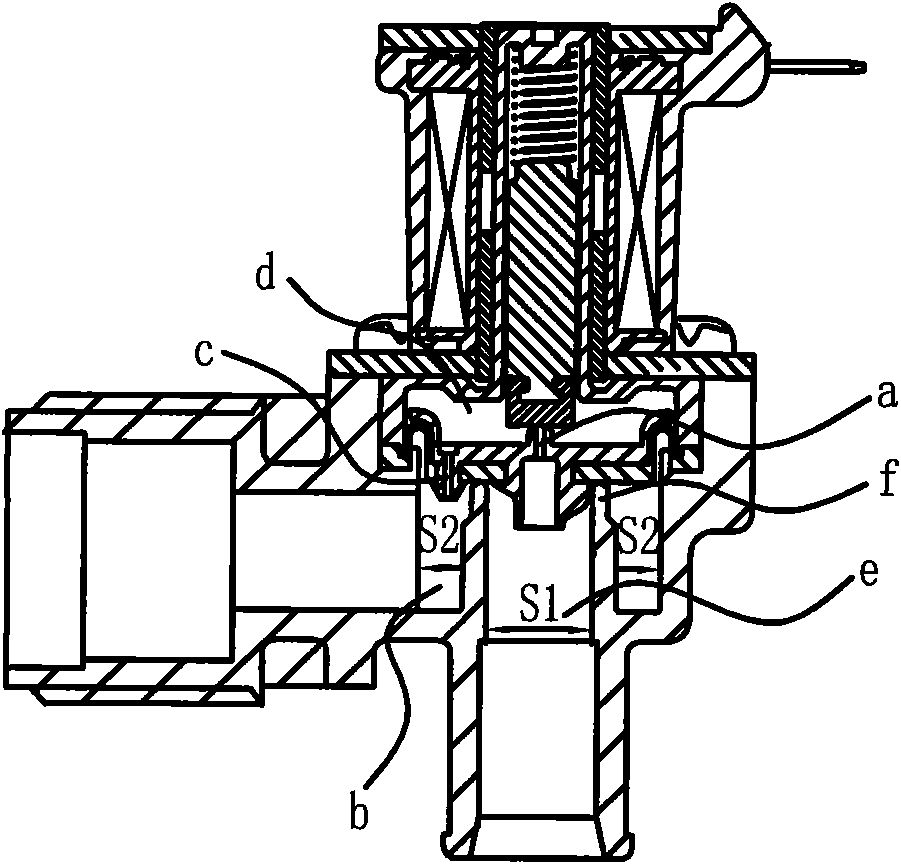

[0058] The electromagnetic water inlet valve of the present embodiment, see Figure 4 , Figure 5 , Figure 6a , Figure 6b , including a valve body 1, the valve body 1 is provided with a water supply chamber 101 and a water outlet chamber 102, there is a valve seat 103 between the water supply chamber 101 and the water outlet chamber 102, the valve seat 103 is matched with a diaphragm 2, and the center of the diaphragm 2 has a perforation 201 Embedded in the matching groove 301 of the diaphragm plate 3, the valve body 1 is provided with a conduit 4, and the radially outwardly expanded lower end 401 of the conduit 4 is pressed against the sealing portion 202 on the periphery of the diaphragm 2 to form a back pressure chamber 104. The center of the diaphragm plate 3 A guide hole 302 is opened at the top, and a side flow channel 303 is opened on the periphery. The water supply chamber 101 communicates with the back pressure chamber 104 through the side flow channel 303. An ele...

Embodiment 2

[0065] The electromagnetic water inlet valve of the present embodiment, see Figure 9 The difference between this embodiment and the first embodiment is that the diaphragm plate 3 is formed by a combination of the diaphragm A31 and the diaphragm B32, and the water inlet 3201 on the diaphragm B32 is formed by fitting the diaphragm A31 and the diaphragm B32. The pressure loss chamber 33 and the back pressure chamber inlet 3101 on the partition A31 constitute the side flow channel 303 .

[0066] Compared with the first embodiment, the manufacturing process of this embodiment is different due to the difference in the structure of the diaphragm plate. In practice, the user can make a choice according to the needs.

Embodiment 3

[0068] The electromagnetic water inlet valve of the present embodiment, see Figure 10There are one or several protrusions 34 on the outer periphery of the diaphragm plate 3, and there are fitting grooves 3401 on the protrusions, and the outer periphery of the diaphragm 2 also has corresponding holes 203, and the fitting grooves 3401 embedded in the hole 203. Other structures are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com