Hinge device for opening and closing of washing machine cover

A washing machine cover and hinge device technology, applied in washing devices, other washing machines, applications, etc., can solve the problems of torque adjustment difficulty, self-weight reduction, shaking, etc., and achieve the effect of damper, improve safety, and easy lifting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, the specific technical content of the present invention will be further described in detail according to the accompanying drawings.

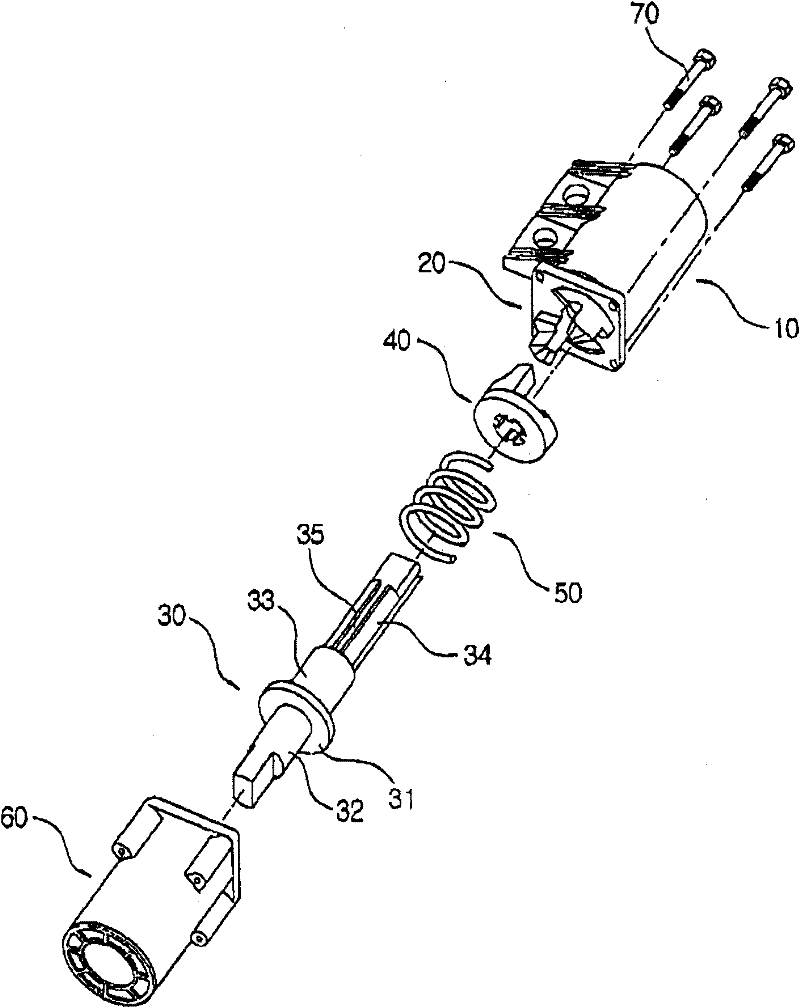

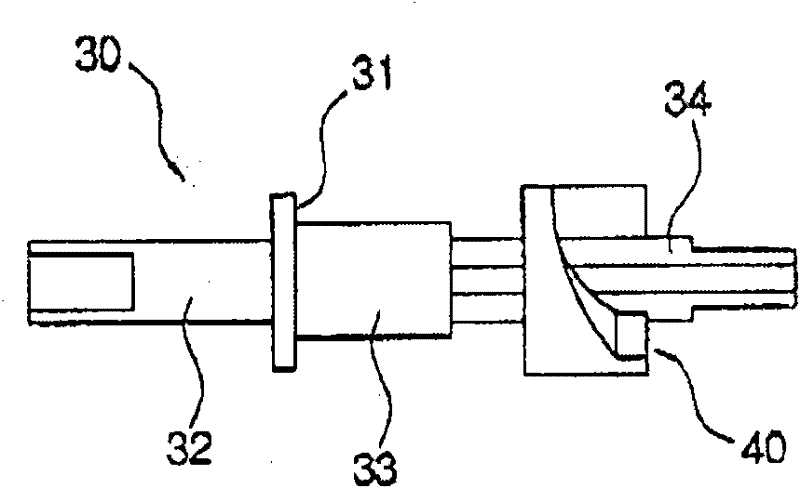

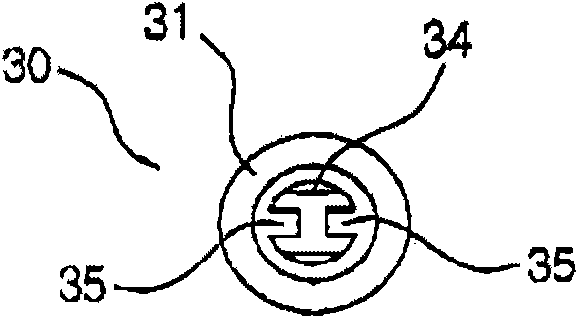

[0026] figure 1 An exploded perspective view showing an embodiment of the present invention, figure 2 A front view showing the joint state of the hinge shaft and the driven cam of this embodiment, image 3 and Figure 4 A side view of the hinge shaft and a side view of the driven cam of this embodiment are shown.

[0027] The hinge device 100 for opening and closing the washing machine cover of the present invention has: a shaft damper 10, which is fixedly installed inside the hinge connection part 210 of the washing machine cover 200, generates a variable torque corresponding to the rotation angle, and rotates in one direction. The damping force is set to be larger; the driving cam 20 is fixedly arranged at the front end of the shaft damper 10, and transmits the rotational force of the shaft damper 10 to the driven cam 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com