Cotton collecting device of roving machine

A technology of roving frame and cotton collection, which is applied in textiles and papermaking, etc., can solve the problem that waste flowers cannot be scraped, and achieve the effect of preventing sagging and improving cotton collection effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

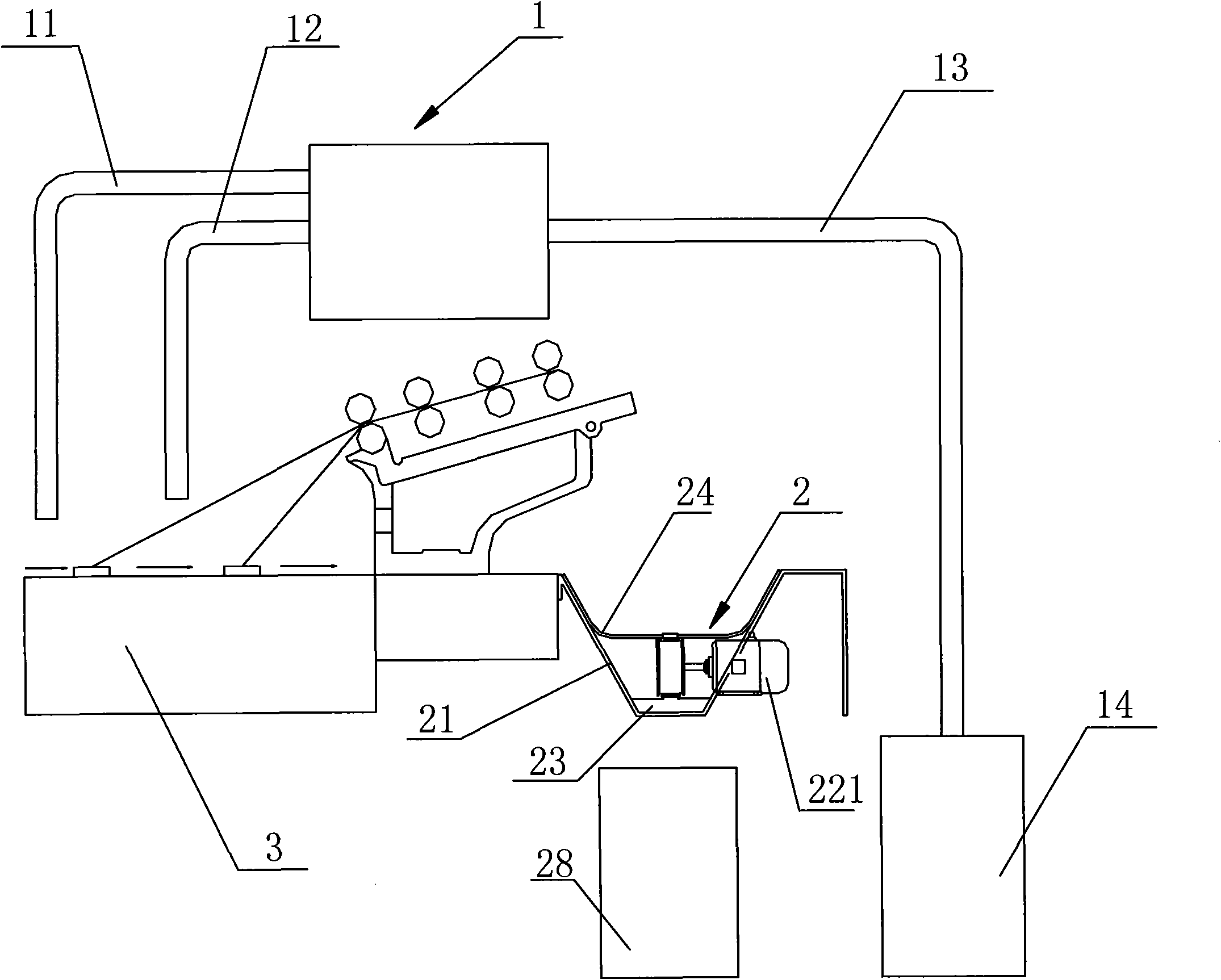

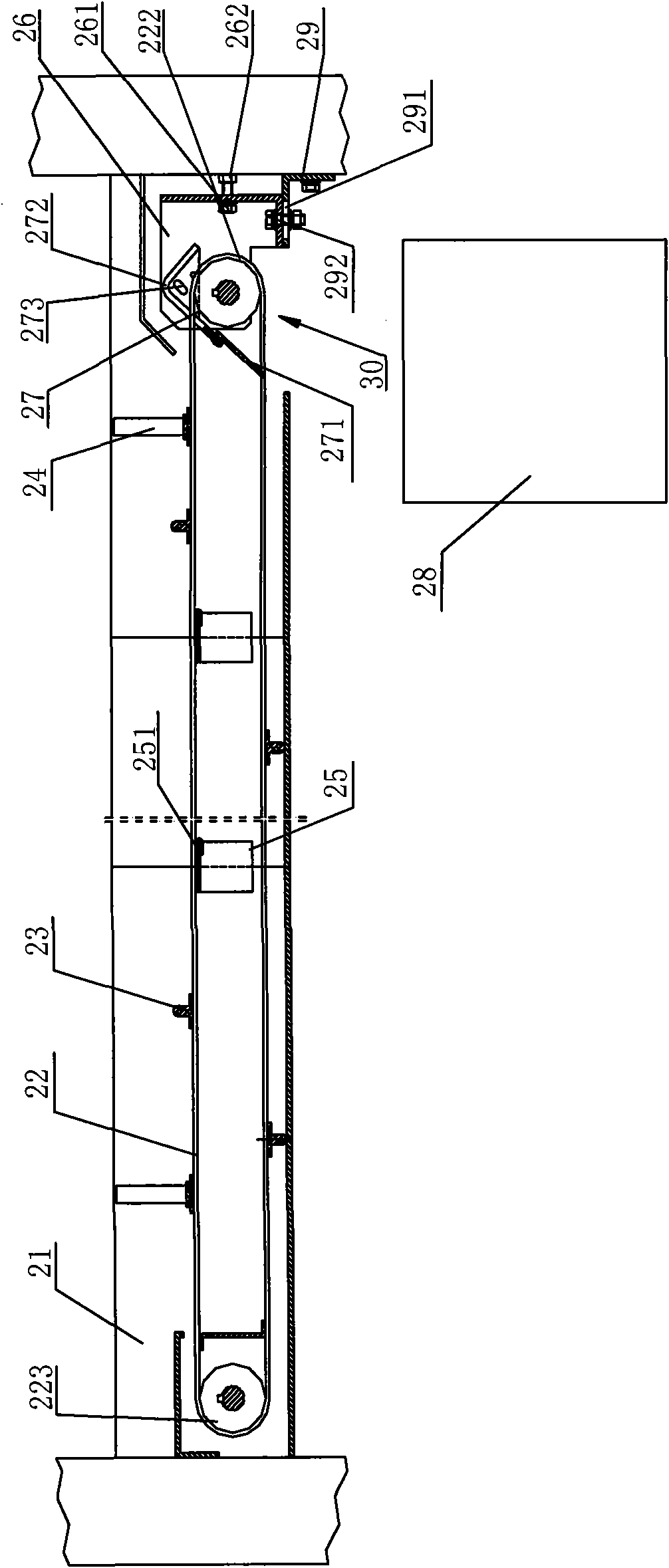

[0022] combine figure 1 and figure 2 , a roving frame cotton collection device, comprising a blowing and suction cleaner 1 located above a roving frame body 3 and a cotton collector 2 located at the rear side of the roving frame body 3 . Above-mentioned blowing and sucking cleaner 1 is provided with blowing pipe 11, suction pipe 12, dust discharge pipe 13 and suction fan 14, and the nozzle of blowing pipe 11 and suction pipe 12 is towards roving machine body 3, and dust discharge pipe 13 is connected with suction blower. Fan 14 is connected. The waste flowers on the roving frame body 3 are blown up by the blowing pipe 11 of the above-mentioned blowing cleaner, and part of the blown waste flowers are inhaled through the suction pipe 12 of the blowing cleaner, and then passed through the dust discharge pipe. 13 is discharged under the effect of suction fan 14. The cotton collector 2 is used to collect a part of the waste flowers that are blown up and transferred to the rear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com