Hydroxylated tung oil and ester group-aminated preparation method thereof

A technology of hydroxylation and ester-based amines, applied in the field of organic chemical synthesis, can solve the problems of increasing by-products and wasting energy, and achieve the effects of improving utilization rate, reducing dependence and short reaction time

Inactive Publication Date: 2010-09-29

HIGH & NEW TECH RES CENT OF HENAN ACAD OF SCI

View PDF3 Cites 38 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Compared with the aminolysis method, the common disadvantage of the alcoholysis method is that it needs to be carried out at a high temperature (200°C-240°C), which not only wastes energy, but also may increase by-products when reacting at a high temperature for a long time; In addition to obtaining hydroxylated products at a lower temperature, the structure of the product can be more easily controlled and the side reactions are less

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

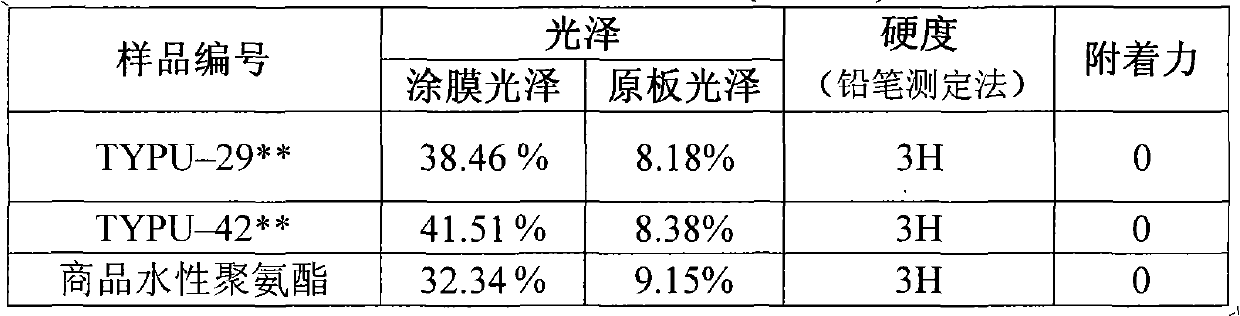

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Login to View More

Abstract

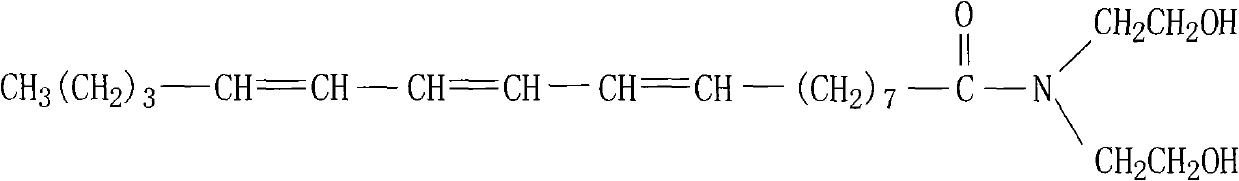

The invention discloses a hydroxylated tung oil and an ester group-aminated preparation method, belonging to the technical field of organic chemosynthesis. In the method, under a certain condition, ester groups in the tung oil and diethanol amine are subjected to aminolysis reaction on the premise of reserving conjugated double bonds, thus the tung oil is hydroxylated to mainly produce a compound containing terminated hydroxyl and three conjugated double bonds. The structural formula of the compound is shown in the specification. The aminolysis reaction product plays an important role in developing and producing processes of leading the tung oil into waterborne polyurethane, not only can combine the advantages of the tung oil and the polyurethane, but also can improve the utilization ratio of tung oil resources as special local products in China and decrease the dependence on petroleum products; and simultaneously, the method has the advantages of simplicity, practicability, high conversion rate and convenience in industrialized production.

Description

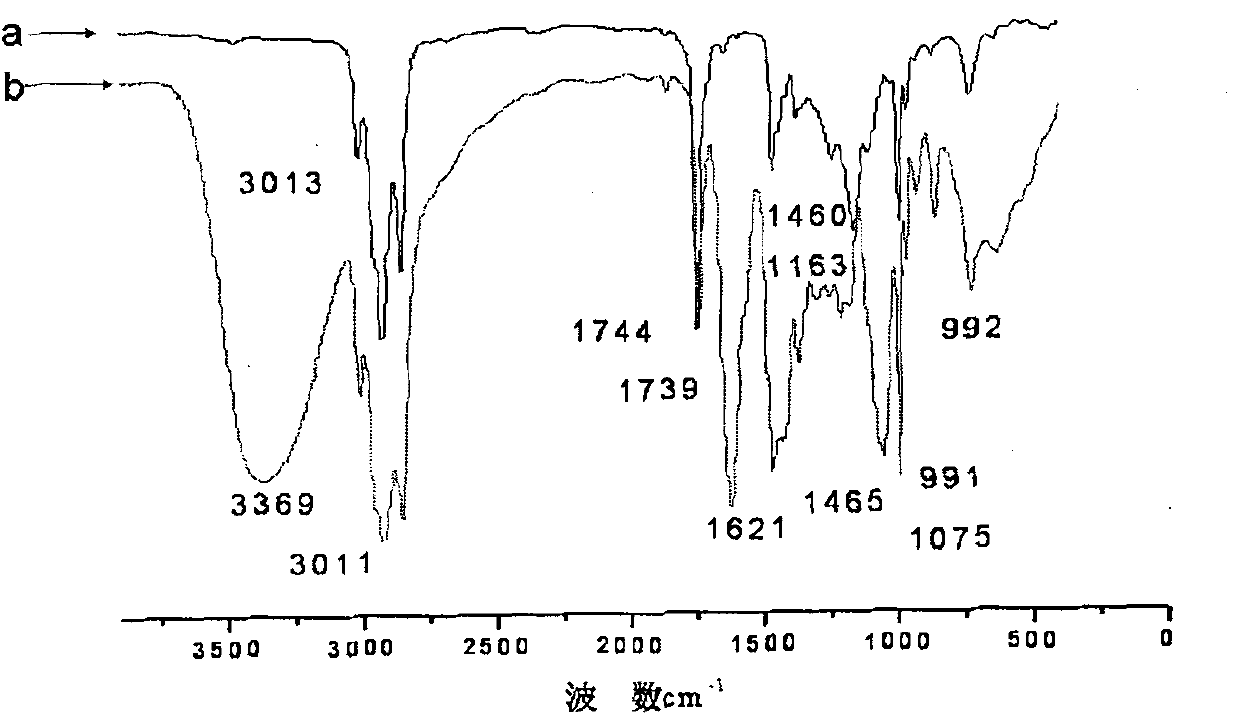

technical field The invention relates to a preparation method of hydroxylated tung oil and ester aminolysis thereof, belonging to the technical field of organic chemical synthesis. Background technique Tung oil is a special product of our country, and it is also an important industrial raw material and a traditional export commodity. The annual output of tung oil in my country is more than 100,000 tons, accounting for 80% of the world's tung oil production and 60% of the world's sales. Therefore, it is of special significance to study tung oil and make more products related to tung oil industrialized. The main component of tung oil is tung oil triglyceride, that is, octadecyl-conjugated-9,11,13-acid triglyceride, and its structural formula is as follows: CH 3 (CH 2 ) 3 -CH=CH-CH=CH-CH=CH-(CH 2 ) 7 -COOCH 2 | CH 3 (CH 2 ) 3 -CH=CH-CH=CH-CH=CH-(CH 2 ) 7 -COOCH | CH 3 (CH 2 ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C11C3/00

Inventor 任志勇姜垒付阳朱诚身朱琰何素琴刘文涛

Owner HIGH & NEW TECH RES CENT OF HENAN ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com