Phosgene treatment method and a method for producing TDI with phosgene

A treatment method, phosgene technology, applied in chemical instruments and methods, preparation of organic compounds, preparation of isocyanic acid derivatives, etc., to achieve the effect of reducing the difficulty of system operation and stabilizing operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

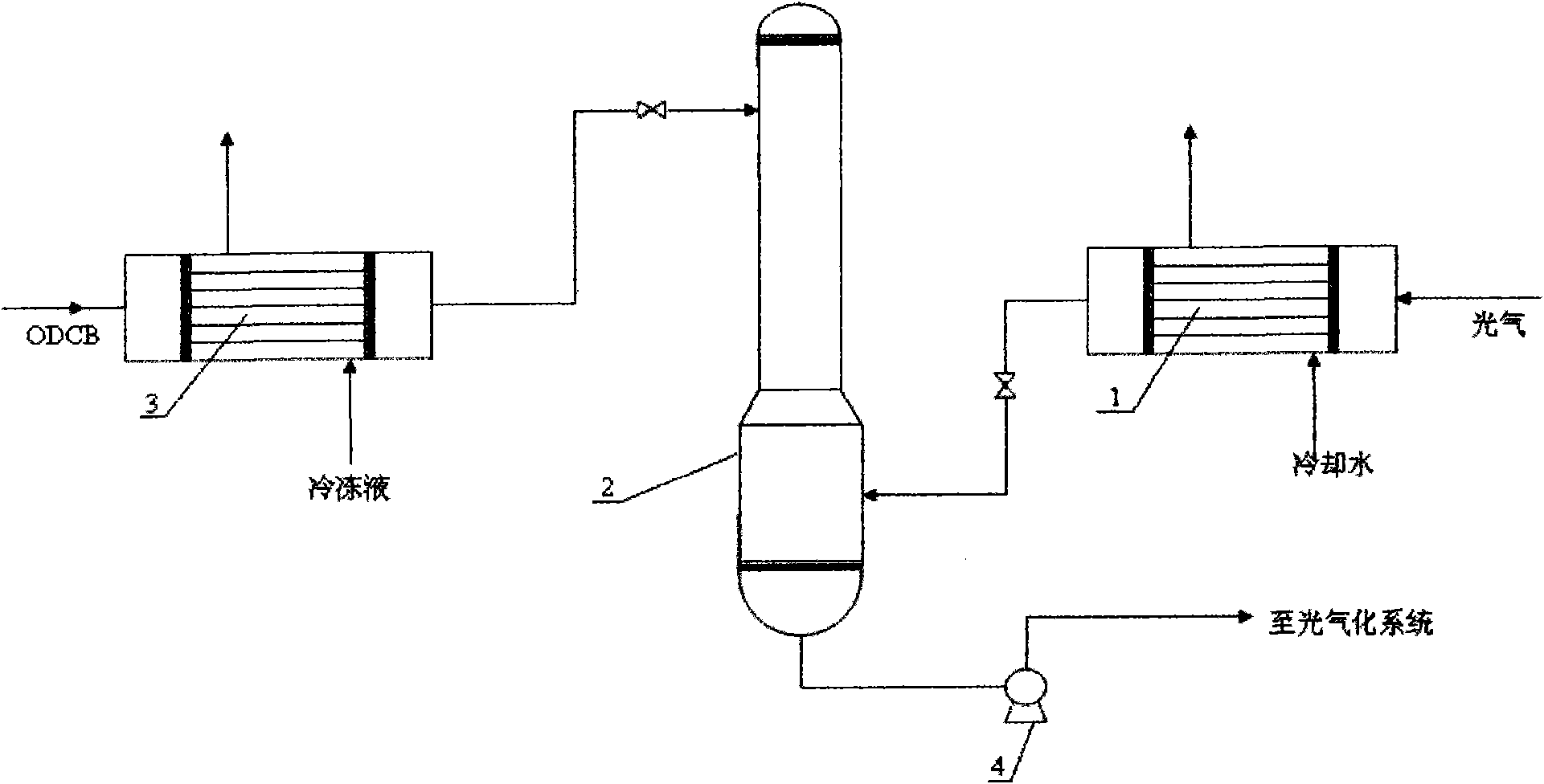

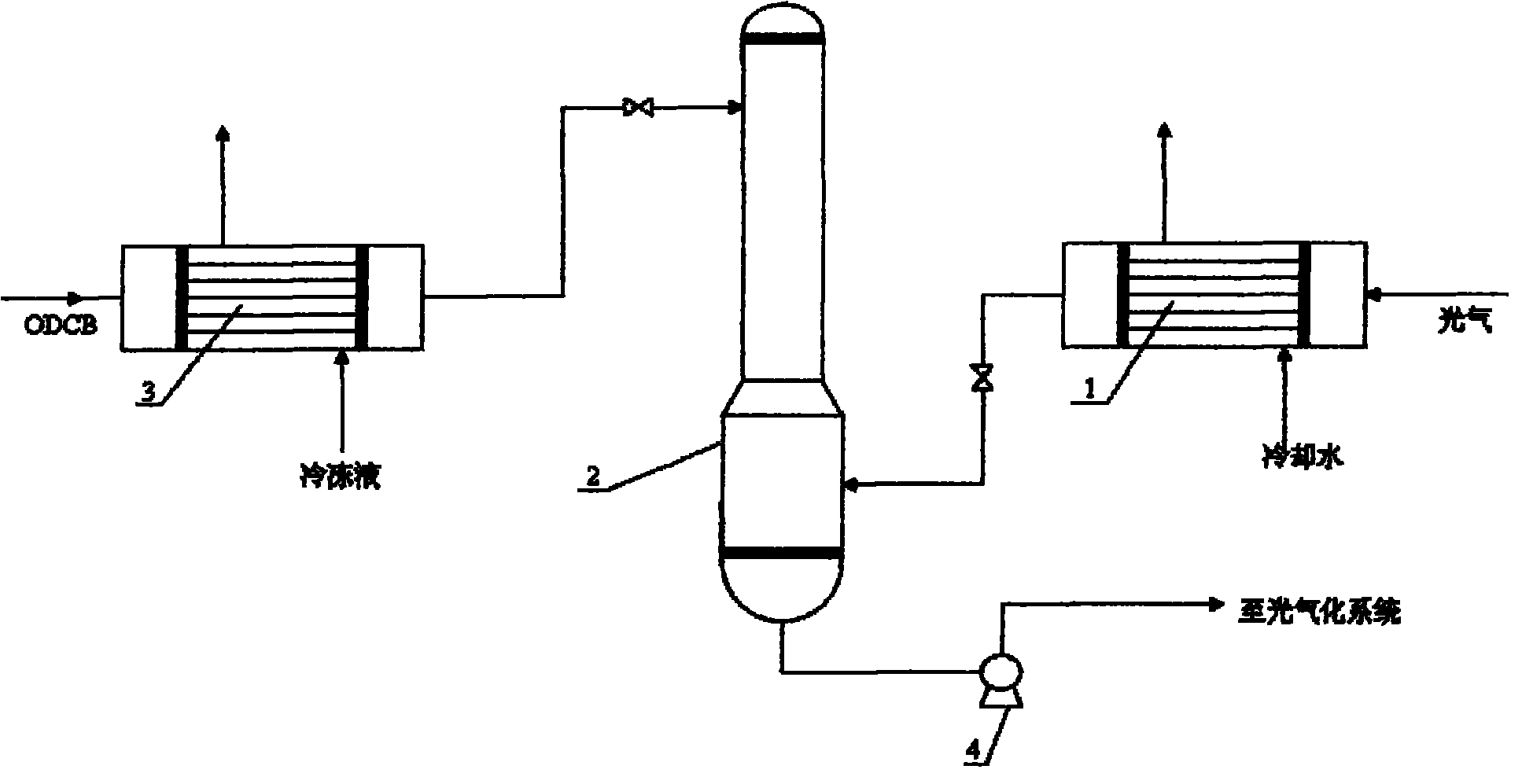

[0011] Below in conjunction with figure, the present invention will be further described:

[0012] The schematic flow chart of the present invention is disclosed in Fig. 1, the temperature of fresh phosgene from the phosgene synthesis process is 65°C is passed into the cooler 1 to cool down to 45°C, and then enters the bottom of the phosgene absorption tower 2. The 30°C o-dichlorobenzene (ODCB) from the irrigation area is cooled to -10°C through cooler 3 (the coolant in cooler 3 is an aqueous solution of ethylene glycol from -15°C to -20°C) and enters phosgene absorption The upper part of the column, where gaseous phosgene is dissolved in o-dichlorobenzene (ODCB). Then, the ortho-dichlorobenzene (ODCB) that has absorbed phosgene is sent to the phosgenation system through the pump 4 to perform phosgenation reaction to generate TDI.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com