Grabbing device for moving wall/floor tiles

A technology for grabbing devices and wall and floor tiles, which is applied in the direction of manipulators, chucks, manufacturing tools, etc., and can solve the problems of poor placement adaptability, complex structure of the grabbing mechanism, and many grabbing actions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

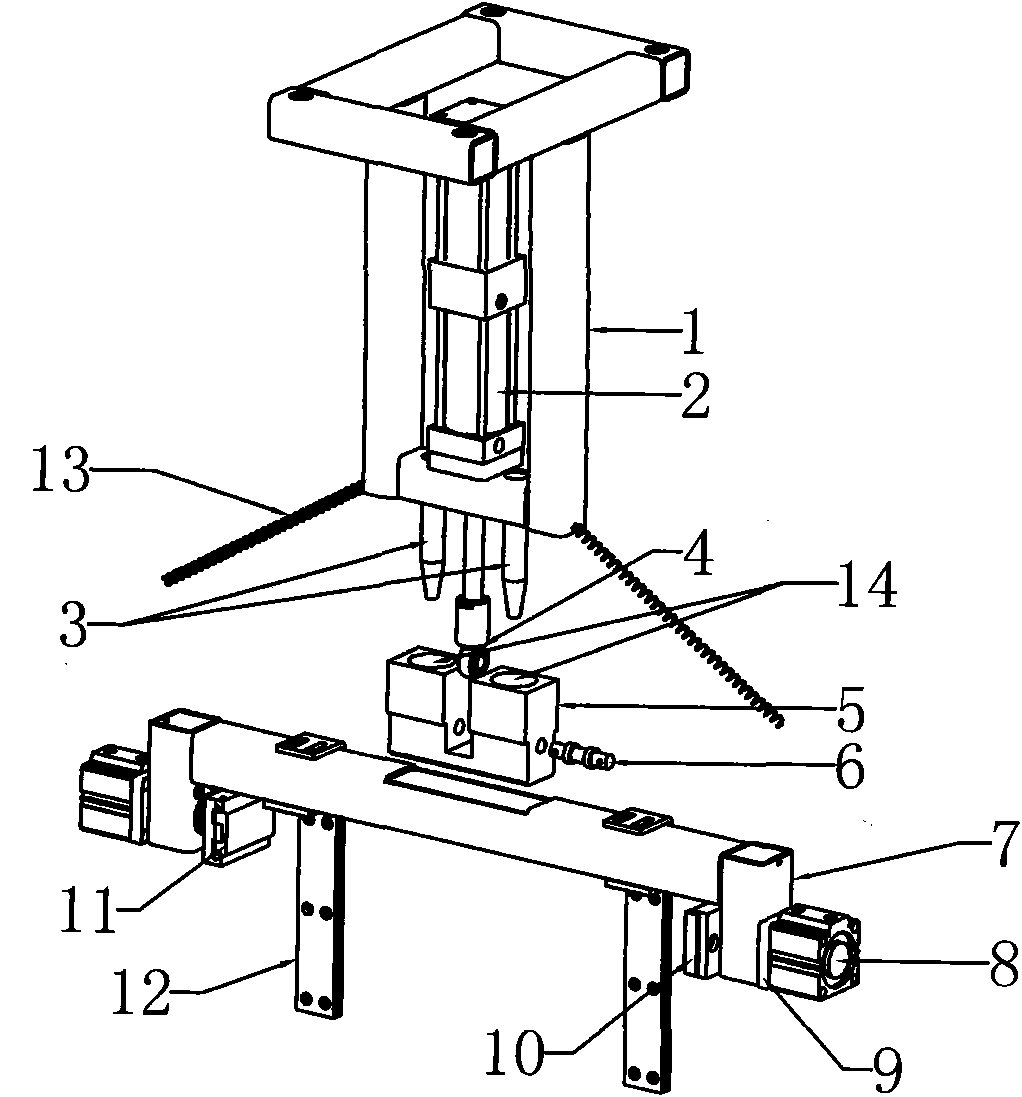

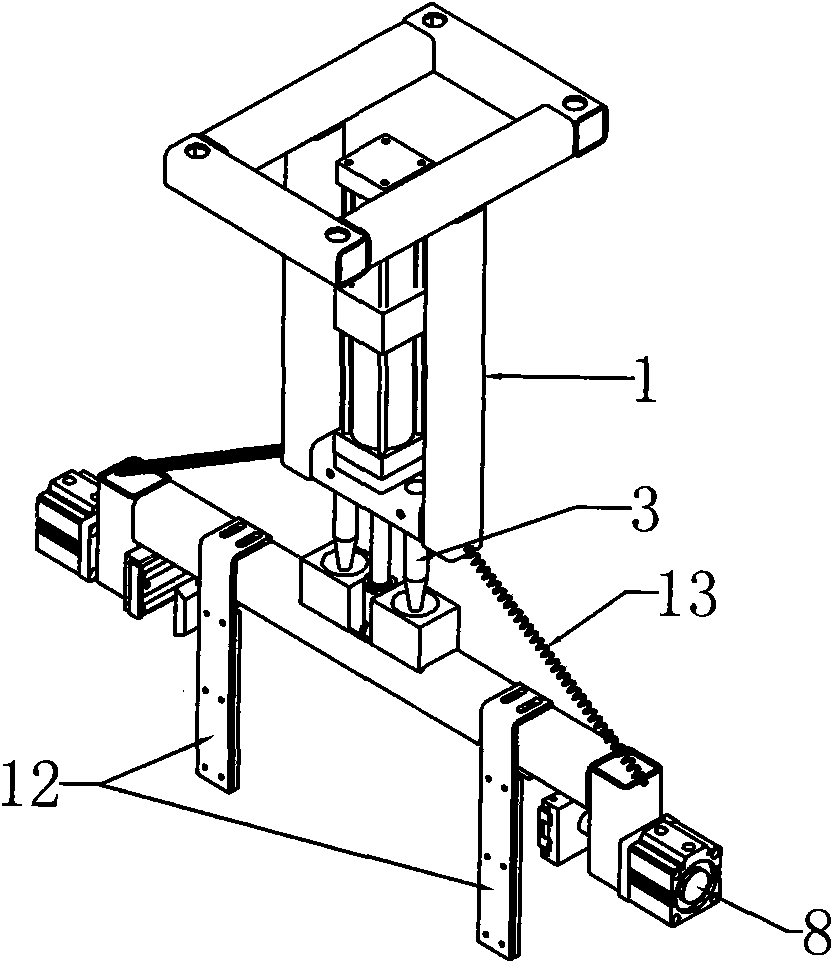

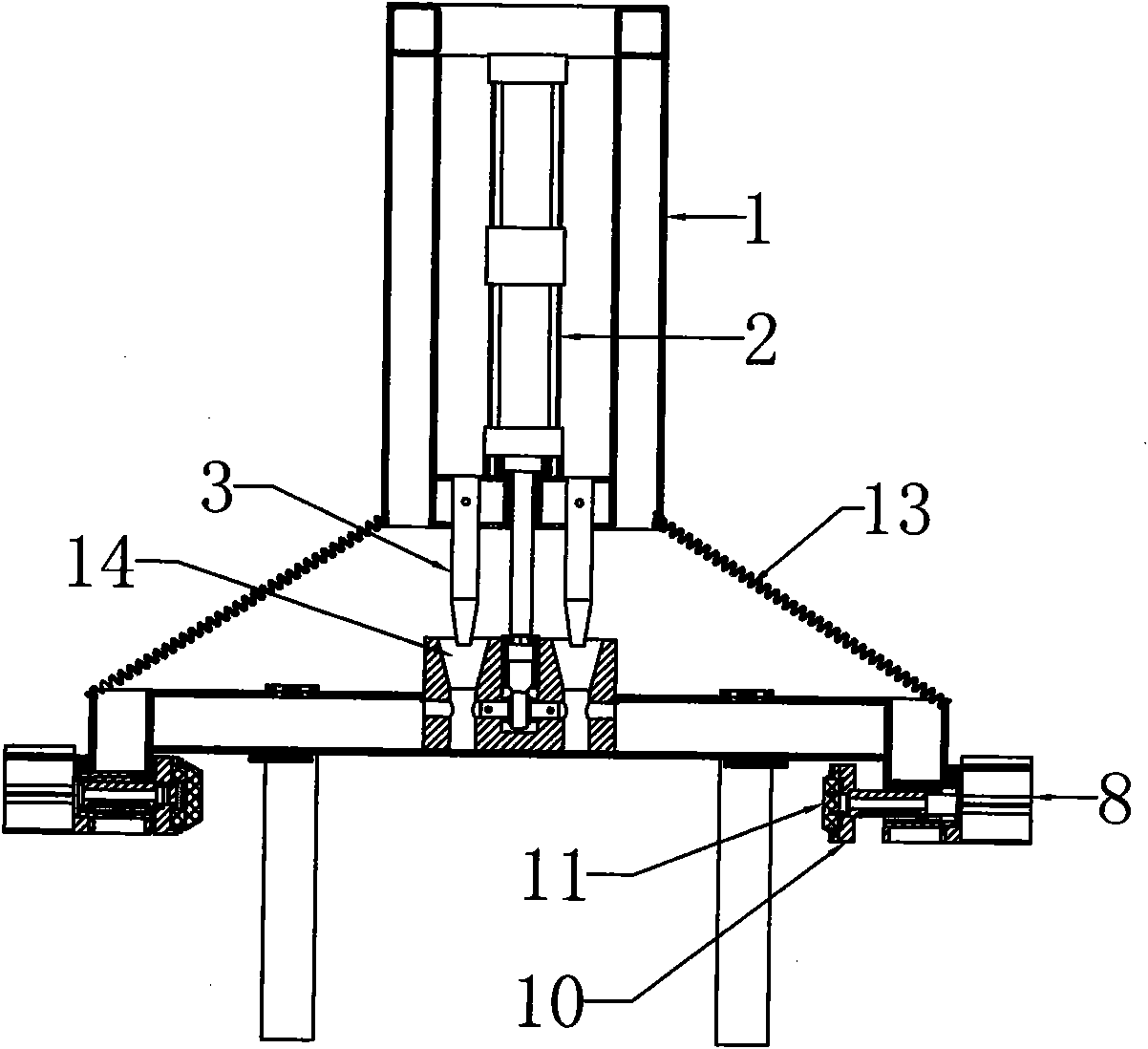

[0015] Attached below figure 1 To attach Figure 4 To further illustrate the present invention, the preferred embodiment of the present invention is: a grabbing device for transferring wall and floor tiles described in this embodiment, which includes an organic base 1, an extraction cylinder 2, a limit pin 3, a fish eye Joint 4, connecting block 5, hinged shaft 6, grasping frame 7, grasping cylinder 8, grasping claw 10, ruler plate 12, return spring 13. Wherein, the cylinder body of the extracting cylinder 2 is fixed in the machine base 1, and the fish-eye joint 4 is installed on the piston rod of the extracting cylinder 2, and is hinged with the connecting block 5 in the gripping frame 7 through the hinge shaft 6. During work, the extracting cylinder 2 drives the grasping frame 7 to descend to the top of the wall and floor tiles that need to be grasped. Support 1 lower end is provided with back-moving spring 13, and back-moving spring 13 is two, is positioned at support 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com