Master-slave modular robot

A robot and main module technology, applied in manipulators, manufacturing tools, etc., can solve the problems of inability to reduce manufacturing costs, fixed structure, inability to quickly repair and replace, and achieve the effects of reduced manufacturing costs, rapid assembly, and simple and reliable docking mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

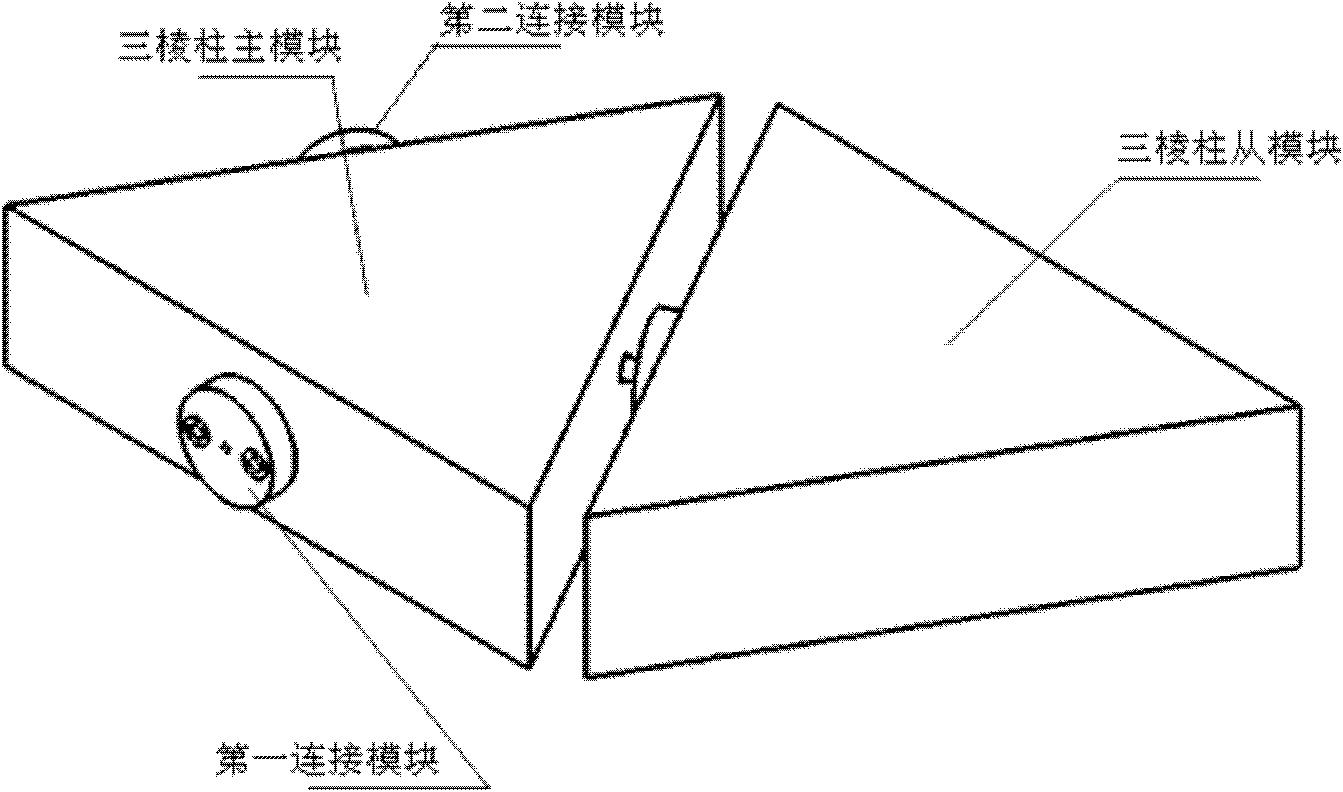

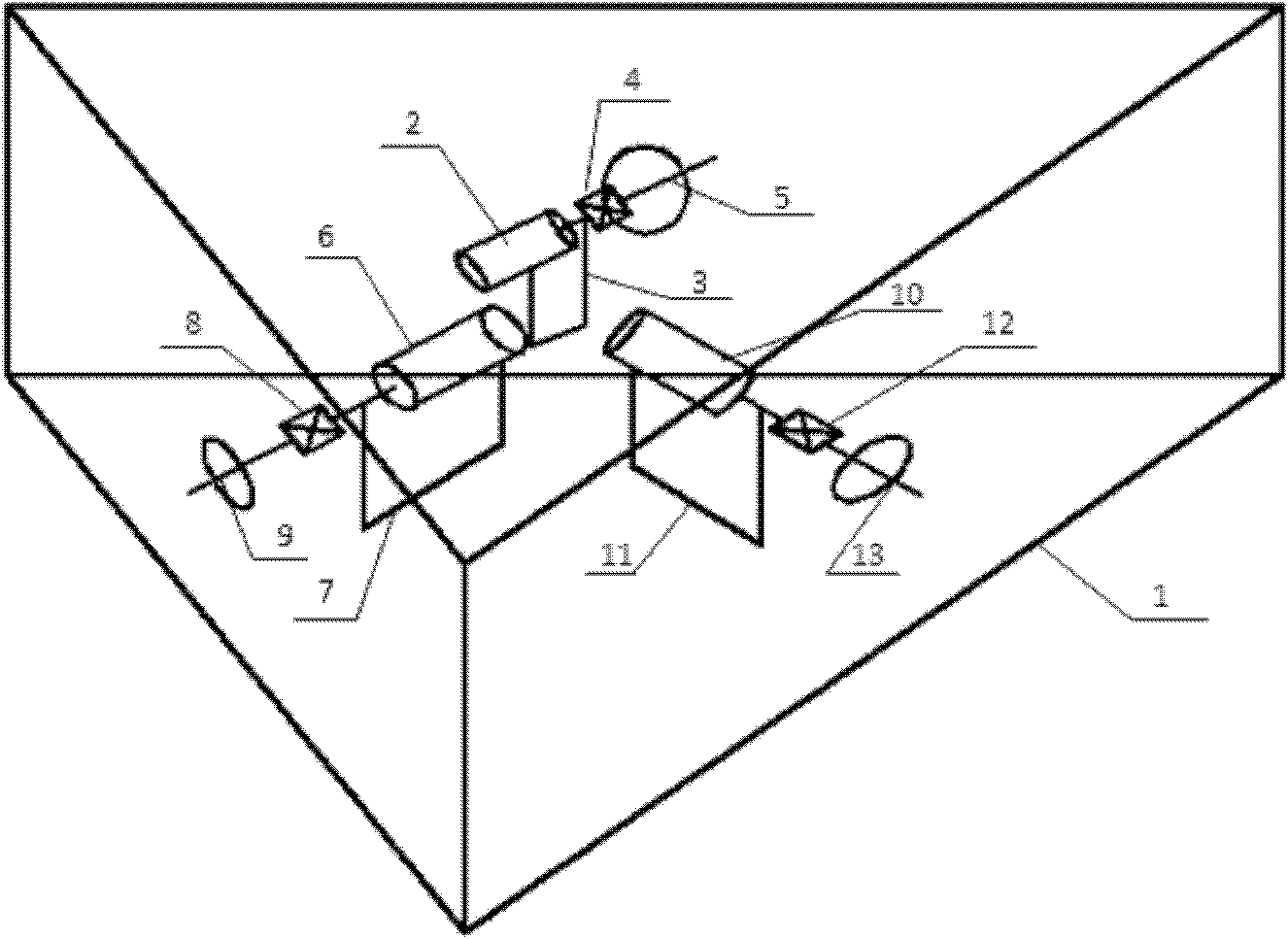

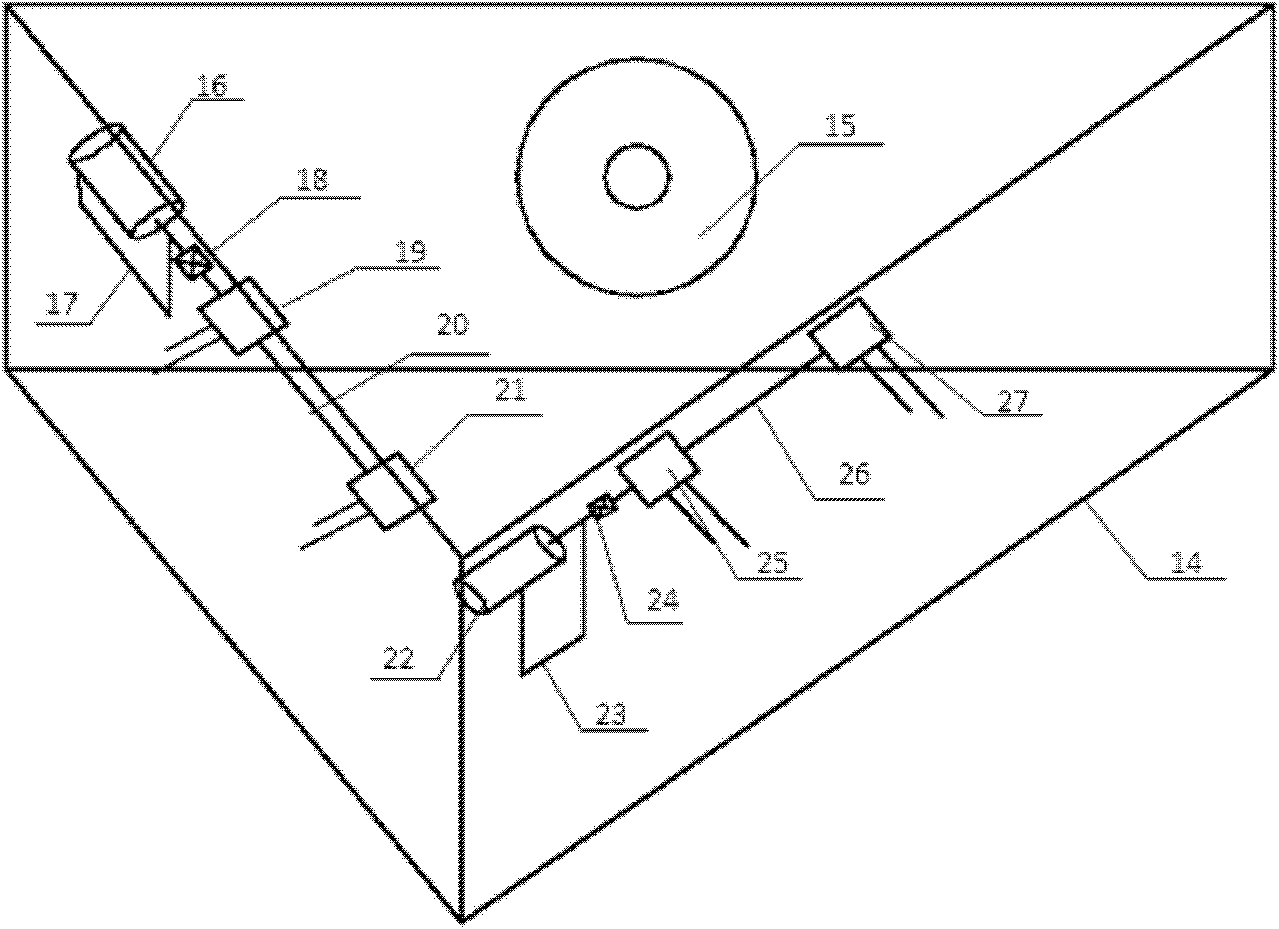

[0029] This embodiment includes several robot units, and each robot unit is connected with four adjacent robot units respectively, such as figure 1 As shown, each robot unit includes: a triangular prism main module, a triangular prism slave module and two connection modules, wherein: the first side of the triangular prism main module is fixed to the first side of the triangular prism slave module, and the three The second side of the prism main module is connected with one end of the first connection module, and the other end of the first connection module is connected with the triangular prism in the adjacent first robot unit from the module, and the third side of the triangular prism main module is connected with One end of the second connection module is connected, the other end of the second connection module is connected with the triangular prism slave module in the adjacent second robot unit, and the second side of the triangular prism slave module is connected with the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com