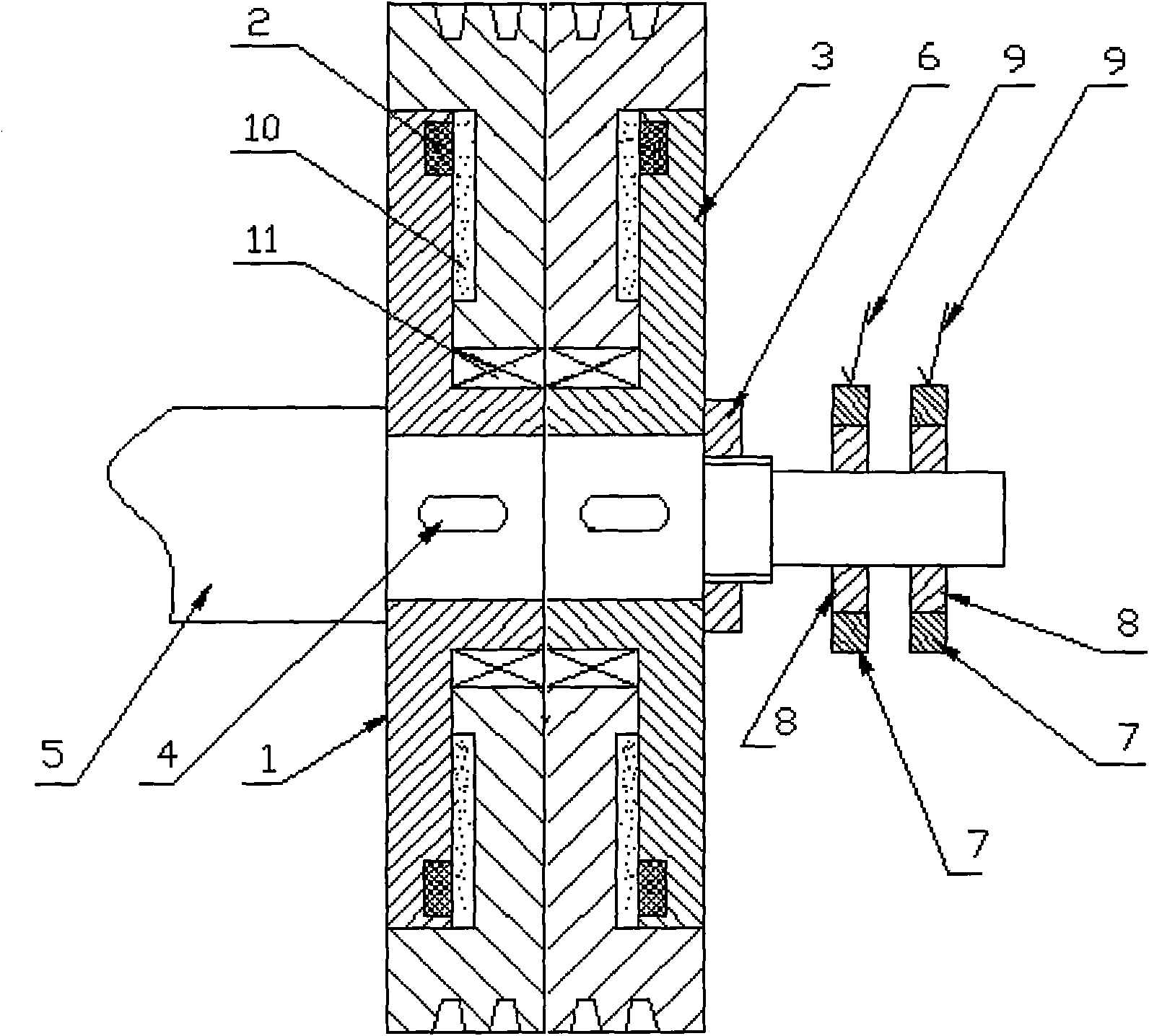

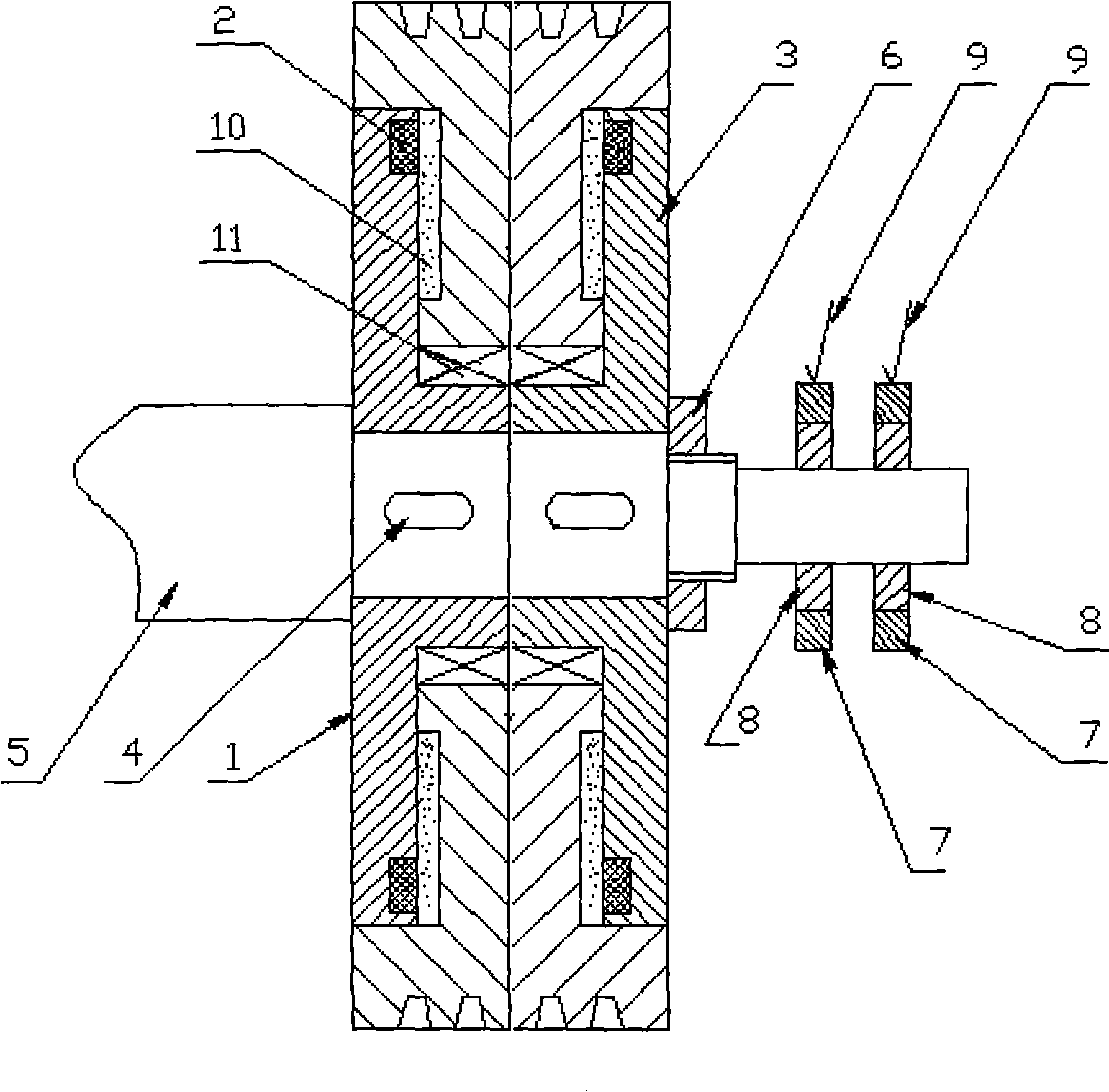

High-speed forging machine two-way clutch brake device

A two-way clutch and brake technology, applied in the field of forging machinery, can solve the problems of not being able to meet the performance requirements of high-speed forging machinery, large parts and space, and consume more energy, and achieve rapid and reliable combination and separation, less transmission inertia, and space volume little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Described flywheel (1) is installed on the outer circle of the hollow shaft of drive disc (3) by bearing (11), and drive disc (3) is installed on one end of crankshaft (5) by the hollow shaft that is connected with it, and It is fixed to the crankshaft (5) by the key (4). An annular groove is formed on the opposite side of the drive disc (3) to the flywheel (1), and the coil (2) is installed in the groove. A closed space is formed between the opposite side of the driving disc (3) to the flywheel (1) and the flywheel (1), during which an appropriate amount of magnetic powder (10) is filled, in order to make the driving disc (3) and the flywheel (1) move When the position is fixed, the external thread is produced on the outer circle on the step at one end of the crankshaft (5), and the nut (6) is screwed on the external thread to fix the driving disc (3) and the flywheel (1) on the crankshaft (5). At one end of the crankshaft (5), two insulating rings (8) are respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com