Screw-rod-driven and piston-pressurized sludge pelletizer

A technology of screw drive and granulator, which is applied in the direction of raw material extrusion granulation, dehydration/drying/thickened sludge treatment, etc., which can solve the problems of unstable granulation, low continuous operation rate, and low strength. Achieve the effect of improving equipment working efficiency, high continuous operation rate and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

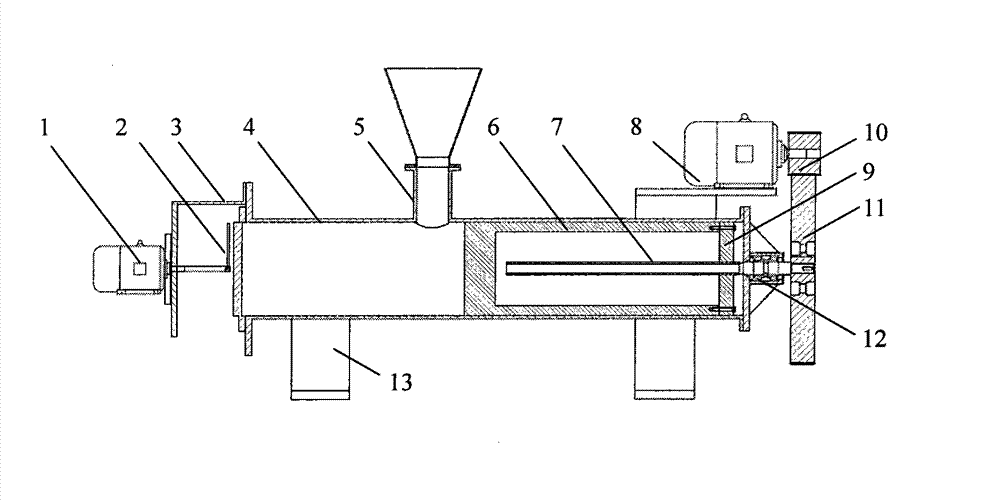

[0009] The screw-driven piston pressurized sludge granulator of the present invention is further described in detail below in conjunction with the accompanying drawings:

[0010] A lead screw driven piston pressurized sludge granulator consists of a motor, a cutting knife (2), a protective cover (3), a main working cylinder (4), a column sleeve piston, a driving gear (10), a power transmission gear (11 ), a bearing seat (12), and a bracket (13), wherein the main working cylinder (4) is in the shape of a hollow cylinder, and uniformly distributed discharge holes are arranged on the front wall of the main working cylinder (4). 4) A protective cover (3) is provided on the outer surface of the front port, a discharge port is provided at the lower end of the protective cover (3), and a first motor (1) is fixedly arranged on the protective cover (3), and the first motor ( The shaft of 1) runs through the protective cover (3) and a cutting knife (2) is arranged at the end, the cuttin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com