Electric air pressure pot

An electric and pneumatic technology, applied in non-pressure containers, fixed-capacity gas storage tanks, gas/liquid distribution and storage, etc., can solve problems such as difficulty in injection volume, and achieve the effect of reducing the possibility of splashing and contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

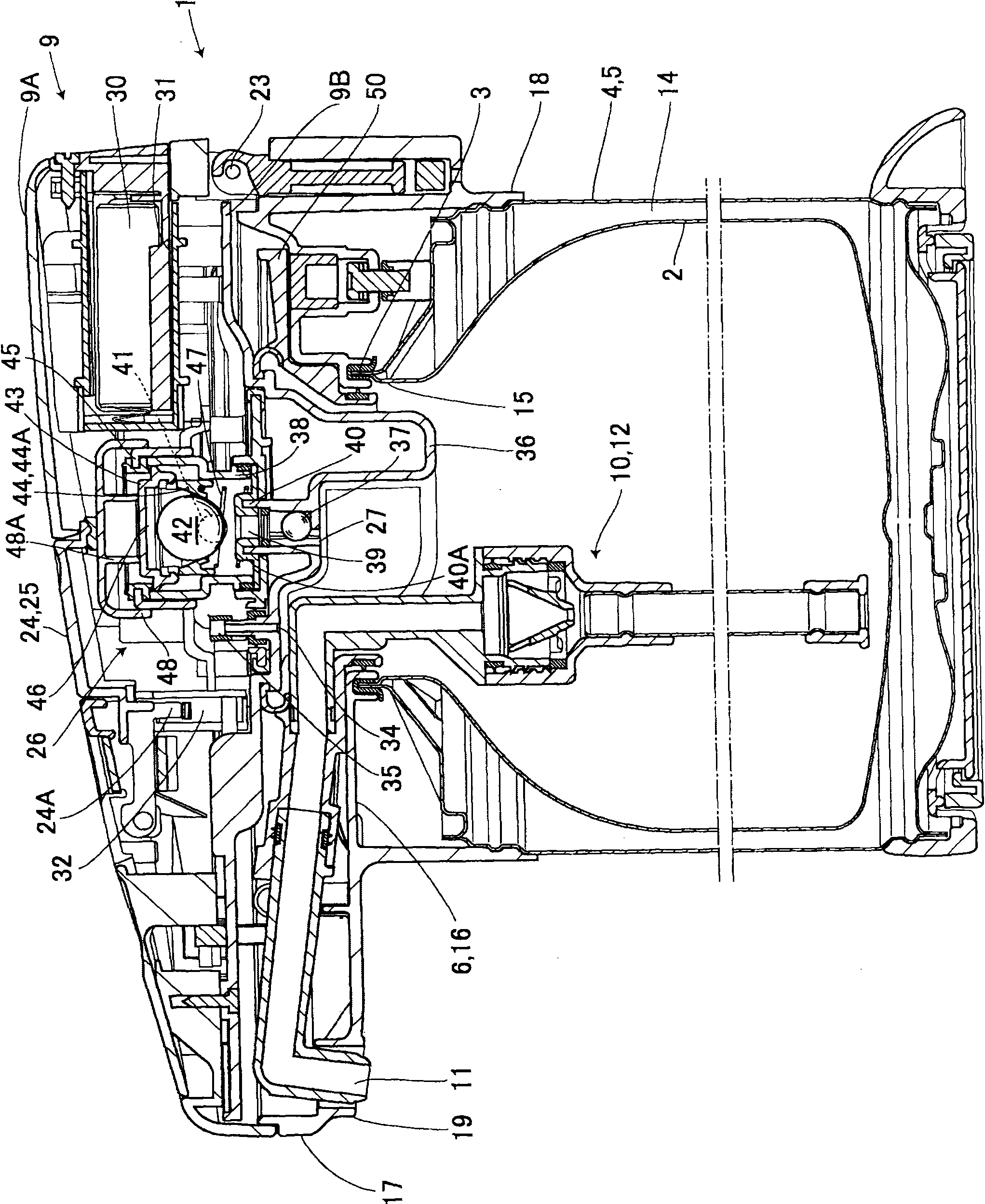

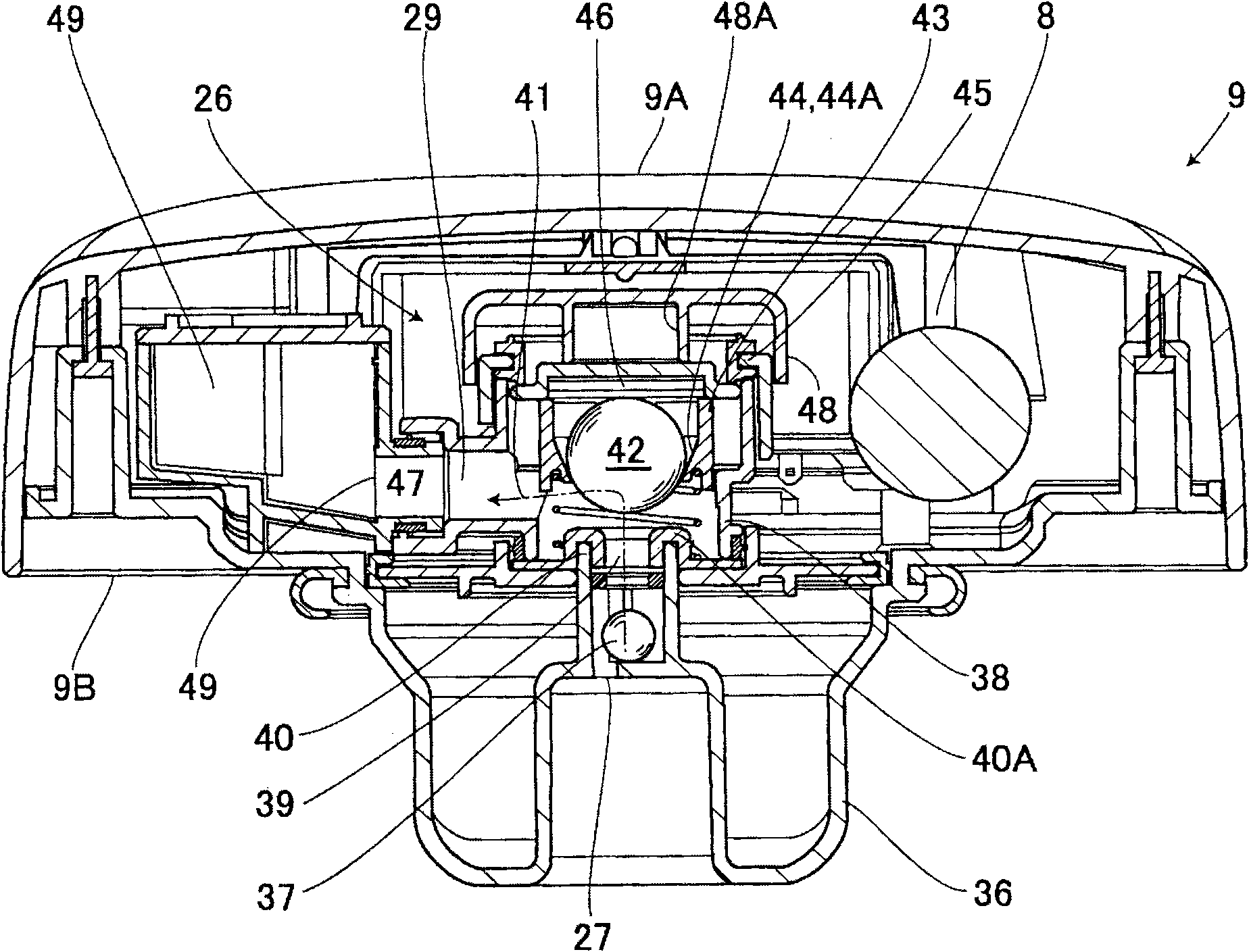

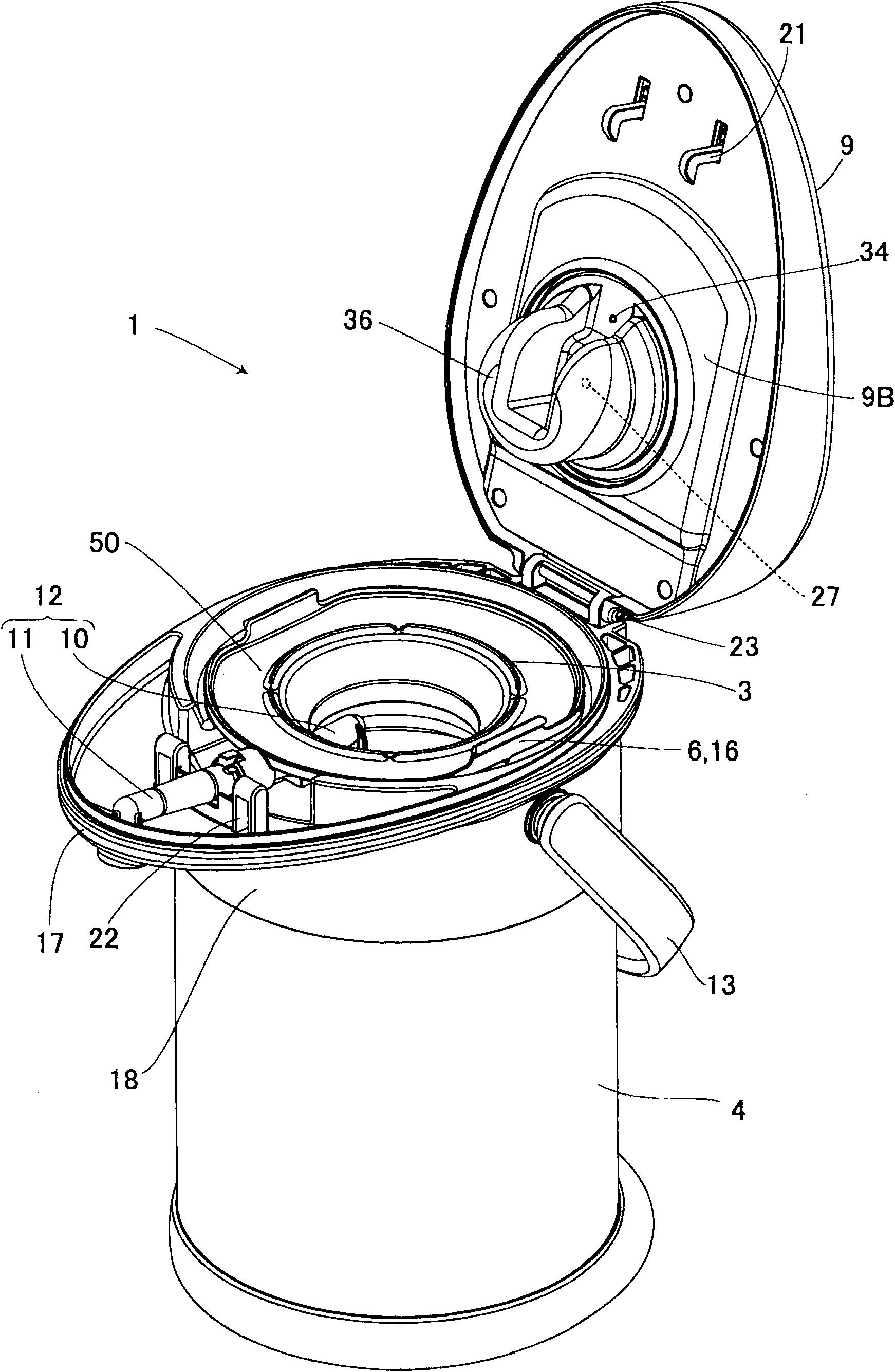

[0043] Figure 1 to Figure 8 Representing embodiment 1, the electric pressure pot 1 includes: a container body 5 having a bottomed inner cylinder 2 for containing liquids such as water and a bottomed outer cylinder 4, and the outer cylinder 4 also serves as a port on the outside of the inner cylinder 2. The role of the outer shell that the parts 3 are connected to each other; a substantially horizontal and substantially disc-shaped shoulder member that is also called a water blocking member or the like and is combined in a manner to cover the outer peripheral upper end side of the outer cylinder 4 and the mouth 3 of the container body 5 6; On the shoulder part 6, an electric pump 8 as an air pump with an electric diaphragm (not shown) is built in and a hollow cover 9 is freely installed; The pipe assembly 12 of the water pipe 10 for discharging the liquid and the water injection pipe 11 communicating with its upper part;

[0044] The container main body 5 has a double vacuum ...

Embodiment 2

[0067] Next, other examples will be described. In addition, the same reference numerals are assigned to the same parts as those in the above-mentioned first embodiment, and detailed description thereof will be omitted.

[0068] Figure 9 It shows Example 2, and in Example 2, the power supply which converted AC commercial power supply into DC voltage was used.

Embodiment 3

[0070] Figure 10 Example 3 is shown, and in Example 3, in addition to Example 2, a rechargeable battery 30A is further incorporated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com