Concentric magnetic gear using squirrel cage type magnetic field regulating device

A magnetic gear and squirrel-cage technology, applied to electrical components, generators/motors, etc., can solve problems such as reduced efficiency, reduced torque, and speed difference, and achieve the effect of improving processing performance and structural rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Form (3) is taken as an example below to further illustrate the structural scheme.

[0023] Form (3) specific implementation method:

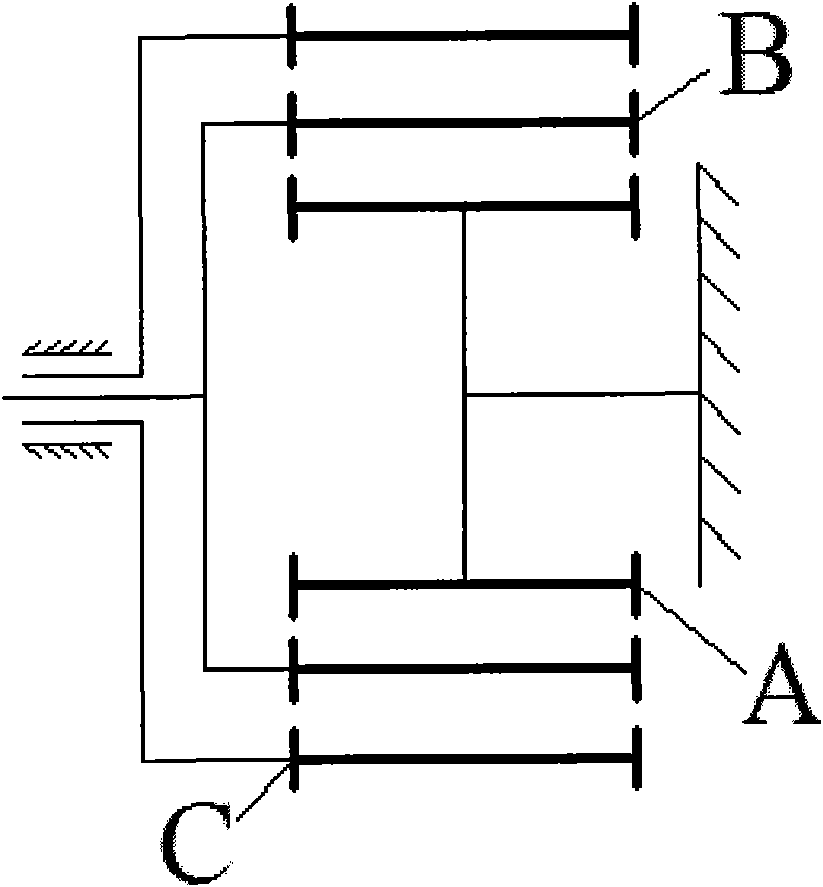

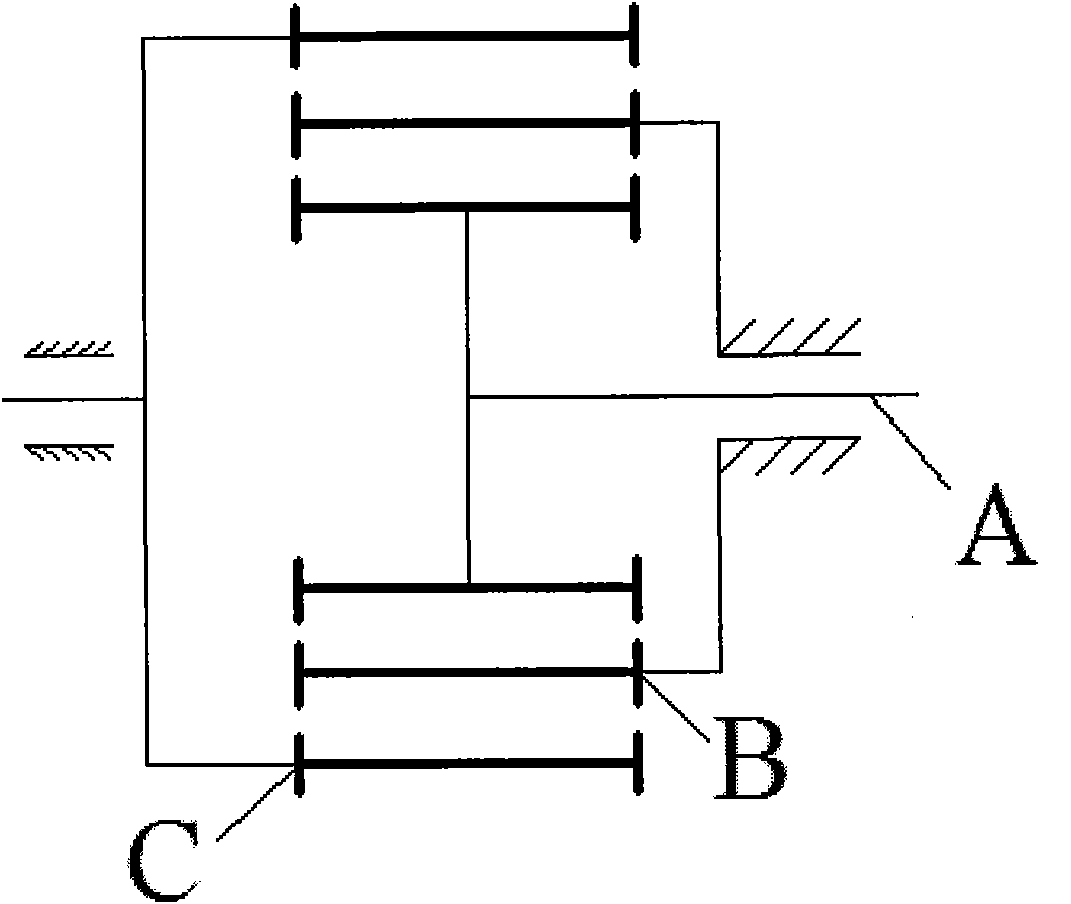

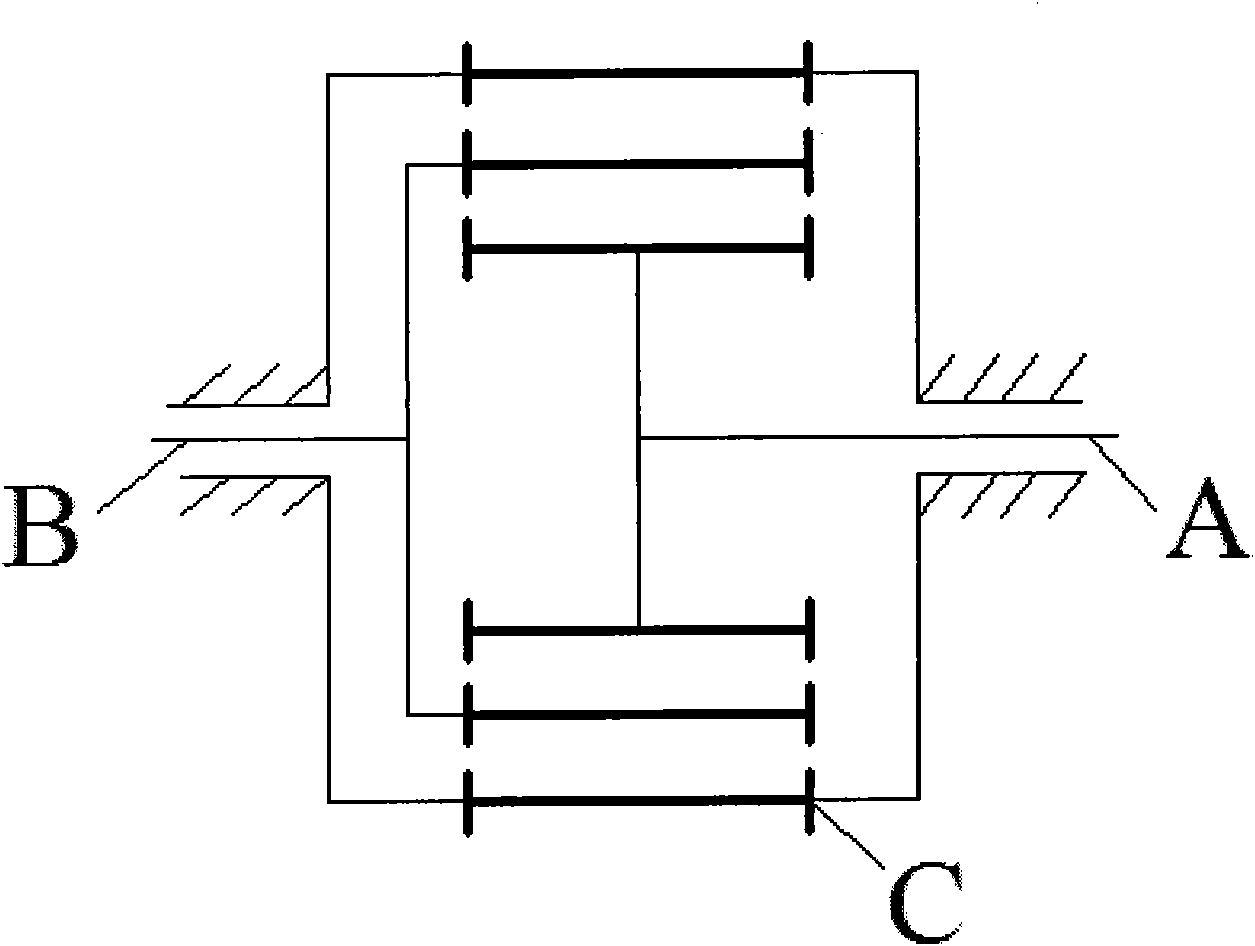

[0024] The overall structure is as Figure 4 As shown, the device includes: high-speed rotor assembly (I), low-speed rotor assembly (II) and stator assembly (III). Among them, the high-speed rotor assembly (I) is the internal permanent magnet structure (A), which is connected to the high-speed shaft through the flat key; the low-speed rotor assembly (II) is the middle magnetic adjustment structure (B), which is connected to the low-speed shaft through the flat key connection; the stator assembly (III) is the external permanent magnet structure (C), which is installed outside the structure.

[0025] The specific structure is: the high-speed rotor assembly (1) includes an inner rotor base body (8) and an inner rotor permanent magnet (7). The permanent magnets (7) of the inner rotor are closely arranged and bonded on the outer surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com