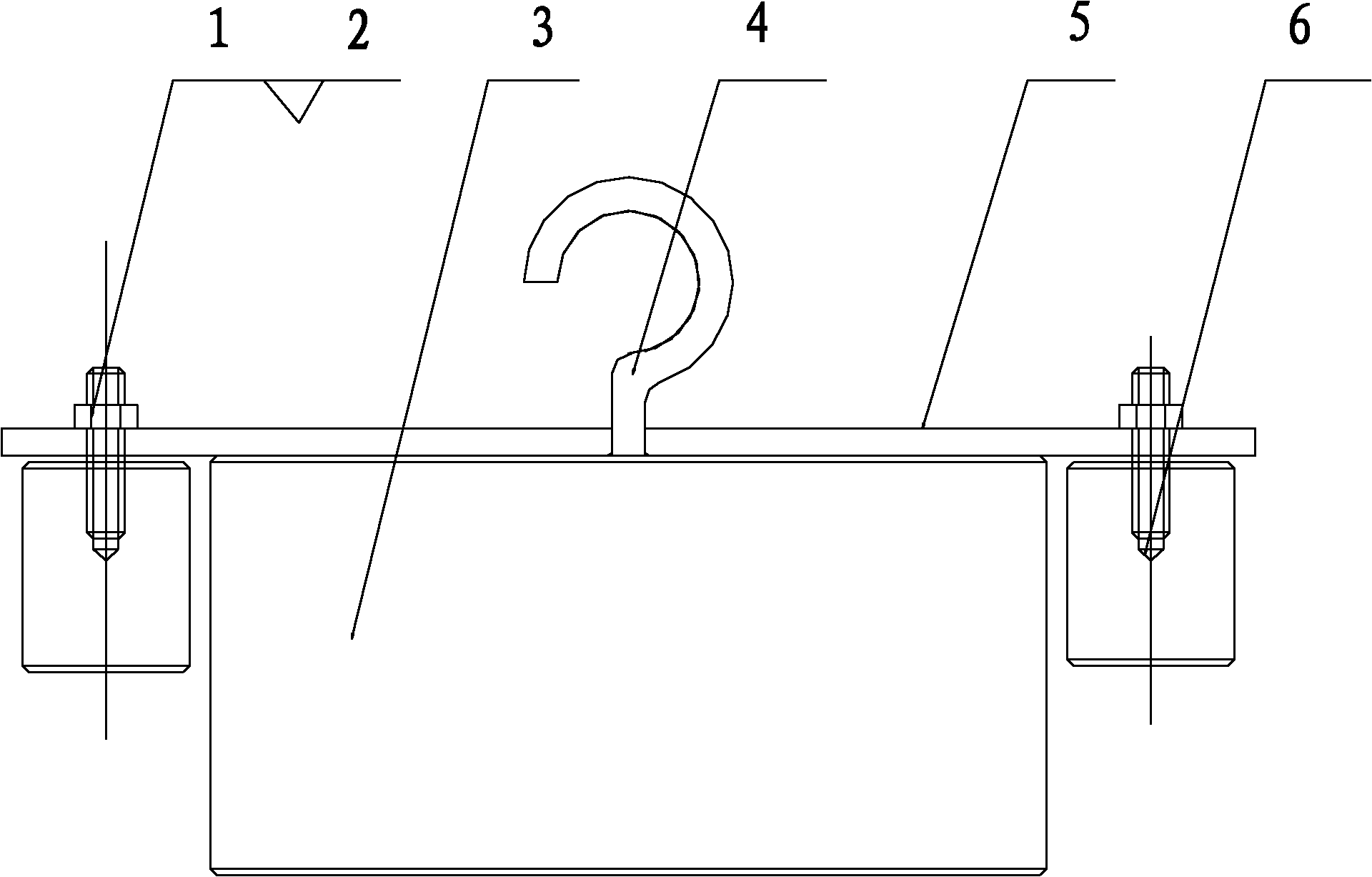

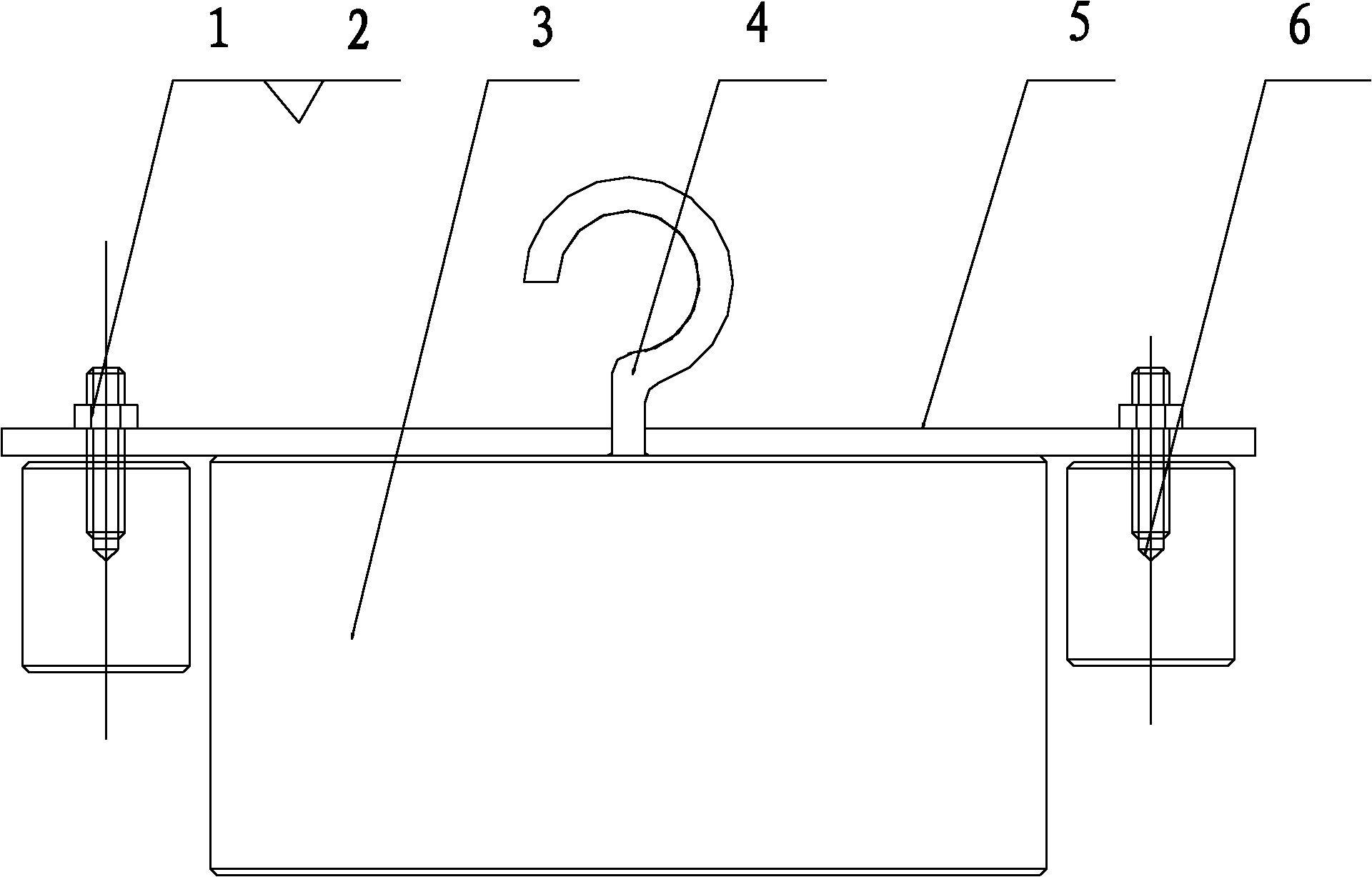

Counterweight balancing device for flat coil winding machine

A counterweight balancing and flat winding technology, applied in measuring devices, coil manufacturing, static/dynamic balance testing, etc., can solve the problems affecting coil winding quality and appearance quality, unfavorable mold management, and low production efficiency. It is beneficial to mold management, safe and reliable equipment operation, and easy adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1 A counterweight balance device for a coil flat winding machine, comprising a counterweight disc 3, a support plate 5 and a roller 6, the counterweight disc 3 is connected with a support plate 5, and the support plate 5 is provided with holes for supporting Plate 5 is fitted with counterweight rollers 6 . The support plate 5 is provided with uniform holes, and the rollers are threaded, and the holes are connected by the adjustment support 1 and the nut 2 to assemble the heavy rollers. The counterweight disc 3 is welded with a suspension hook 4 for hoisting the roller.

[0015] Taking the 18000KW unit as an example, the flat winding process of the magnetic pole coil: 1. First connect the flat winding mold and the base with fastening bolts, then install it on the flat winding machine disk, adjust the position of the mold and fasten the Machine plate and base dovetail handle and firm.

[0016] 2. Discharge the copper after primary annealing on the support tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com