Integral electromagnetic valve

A solenoid valve, integrated technology, applied in the direction of valve details, valve devices, valve housing structure, etc., can solve the problems of increasing fuel injection system assembly work, increasing manufacturing costs, etc., to reduce the burden of research and precision assembly, reduce The effect of manufacturing cost and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in more detail below in conjunction with accompanying drawing example:

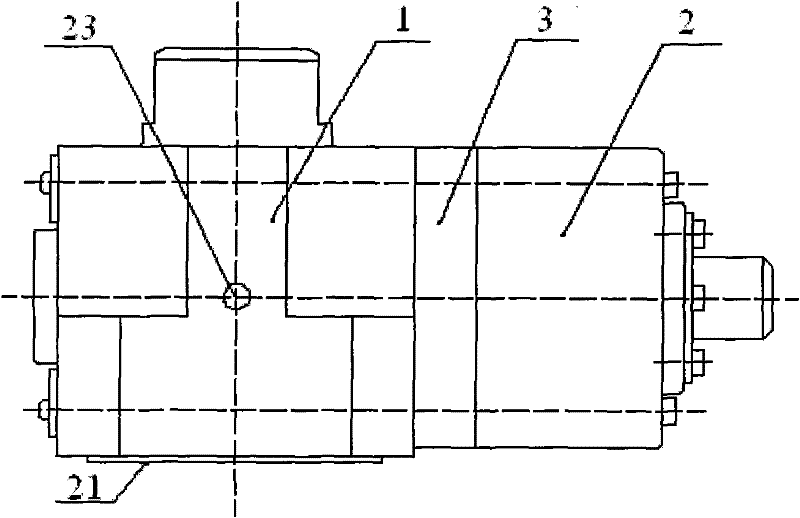

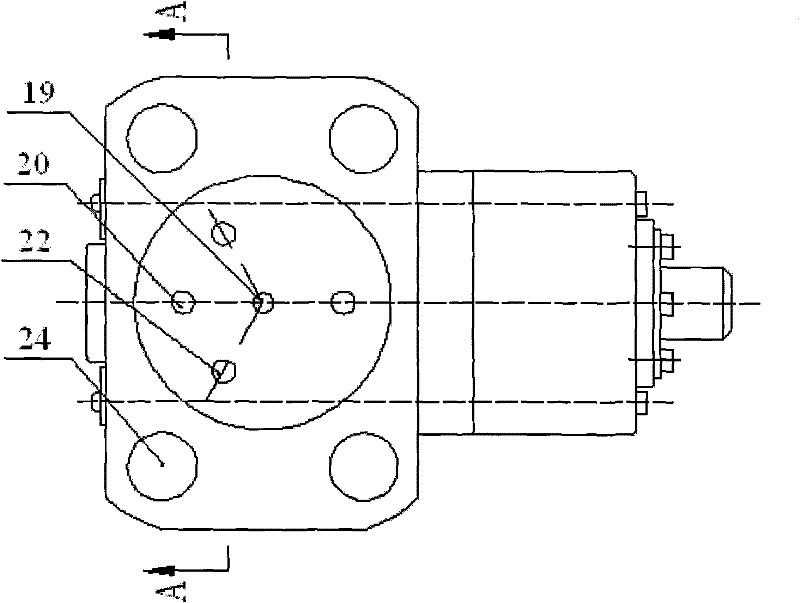

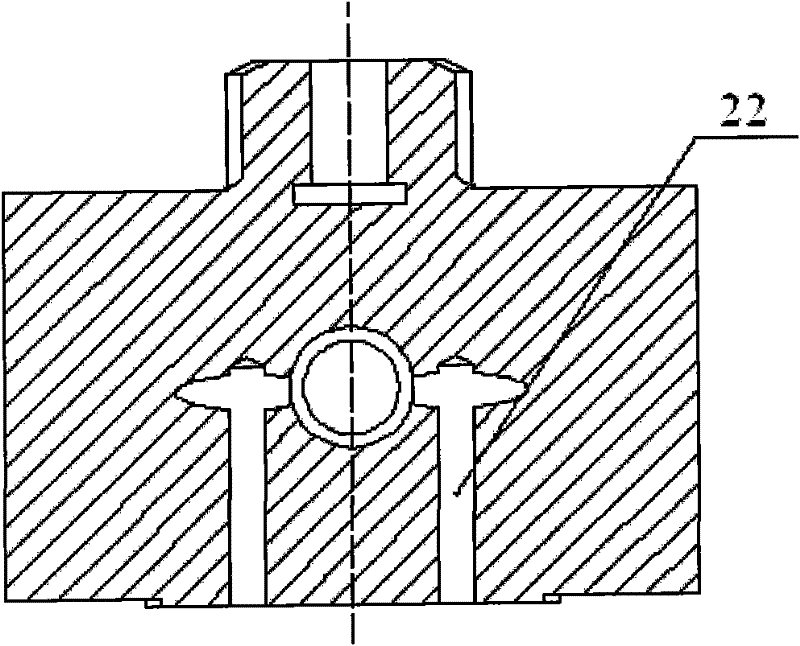

[0022] combine Figure 1-8 , an integral solenoid valve, which is mainly fastened by a valve body 1, an electromagnet housing 2, an electromagnet pad 3, an armature 4, a control valve stem 5, a plug 6, an electromagnet 7, an electromagnetic coil 8, and an armature Screw 9, return spring baffle plate 10, control valve rod return spring 11, return spring seat 12, washer 13 etc. are formed. The solenoid valve is a normally open valve, and the sealing cone surface of the control valve stem 5 is closely matched with the sealing cone hole of the valve body 1 to form the fuel inlet and return control cone surfaces. The armature 4 is connected with the control valve stem 5 through the armature fastening screw 9, so that the control valve stem 5 can move together with the armature 4 through the electromagnetic force of the electromagnet 7 on the armature 4, thereby closin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com