Electric core structure of lithium battery

A lithium battery and cell technology, applied in structural parts, secondary batteries, battery pack parts, etc., can solve problems such as active material shedding, electrode plate breakage, lithium battery short circuit, etc., to reduce breakage, improve capacity, increase The effect of the radius of curvature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

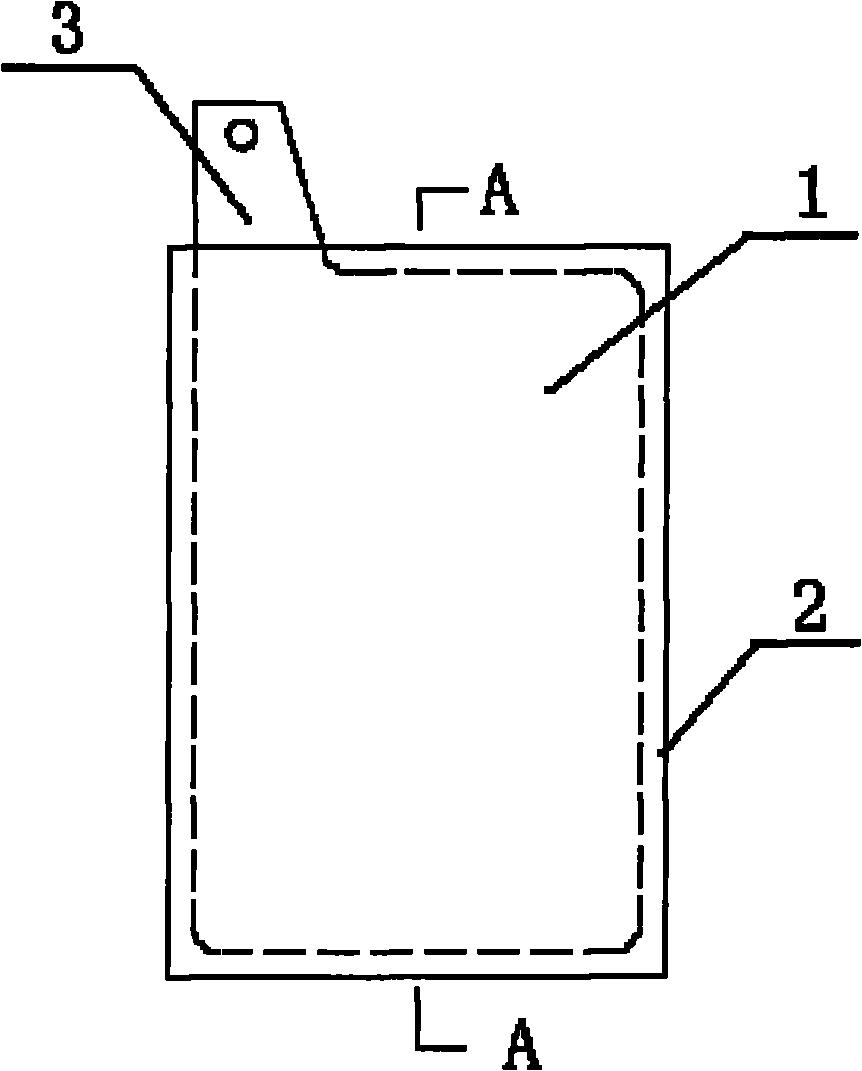

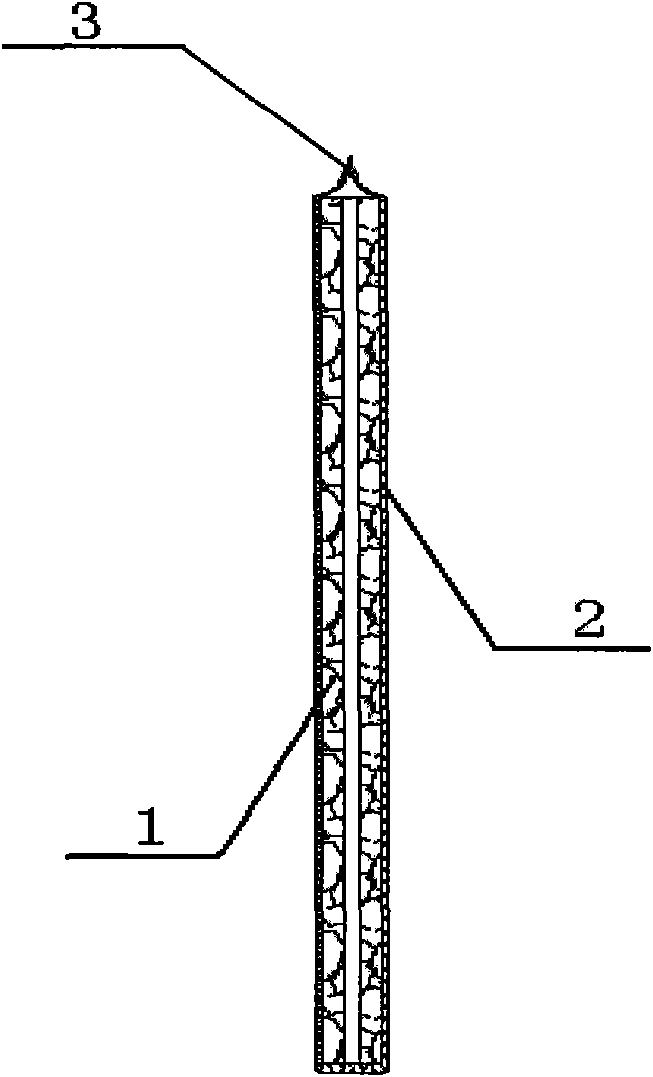

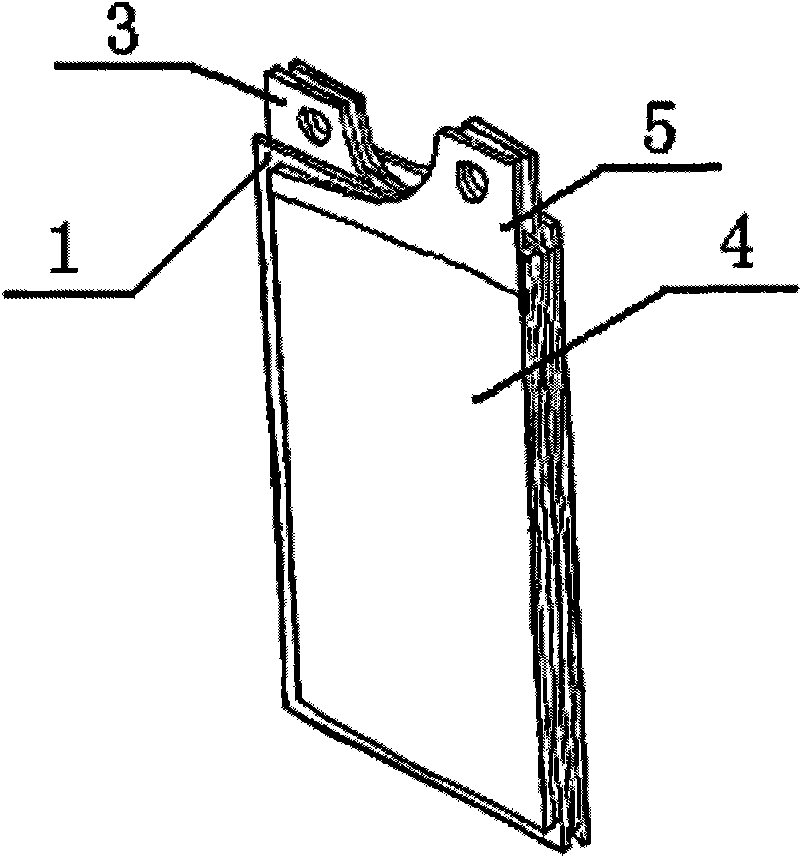

[0017] Such as figure 1 As shown, the positive electrode sheet 1 is inserted into the diaphragm bag 2, and the periphery of the diaphragm bag is sealed by thermal melting, leaving the position of the positive lead-out sheet 3 unsealed, thus forming the positive electrode plate packaged in the diaphragm bag. Such as figure 2 As shown, the positive electrode material is adhered to both sides of the positive electrode current collector to form a positive electrode plate 1, and the periphery of the positive electrode plate 1 is completely wrapped by a separator bag 2 except for the positive electrode lead-out piece 3, forming a layer of positive electrode layer of the inner core of the battery. Such as image 3 As shown, the positive electrode plate 1 and the negative electrode plate 4 packaged in the separator bag 2 are stacked in sequence, wherein the positive electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com