Oil analysis method for diagnosing equipment failure

A technology for oil analysis and equipment failure, applied in particle size analysis, particle and sedimentation analysis, testing of machine/structural components, etc. problems such as low dispersion, to achieve the effect of improving automatic identification ability, rich information, and high definition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

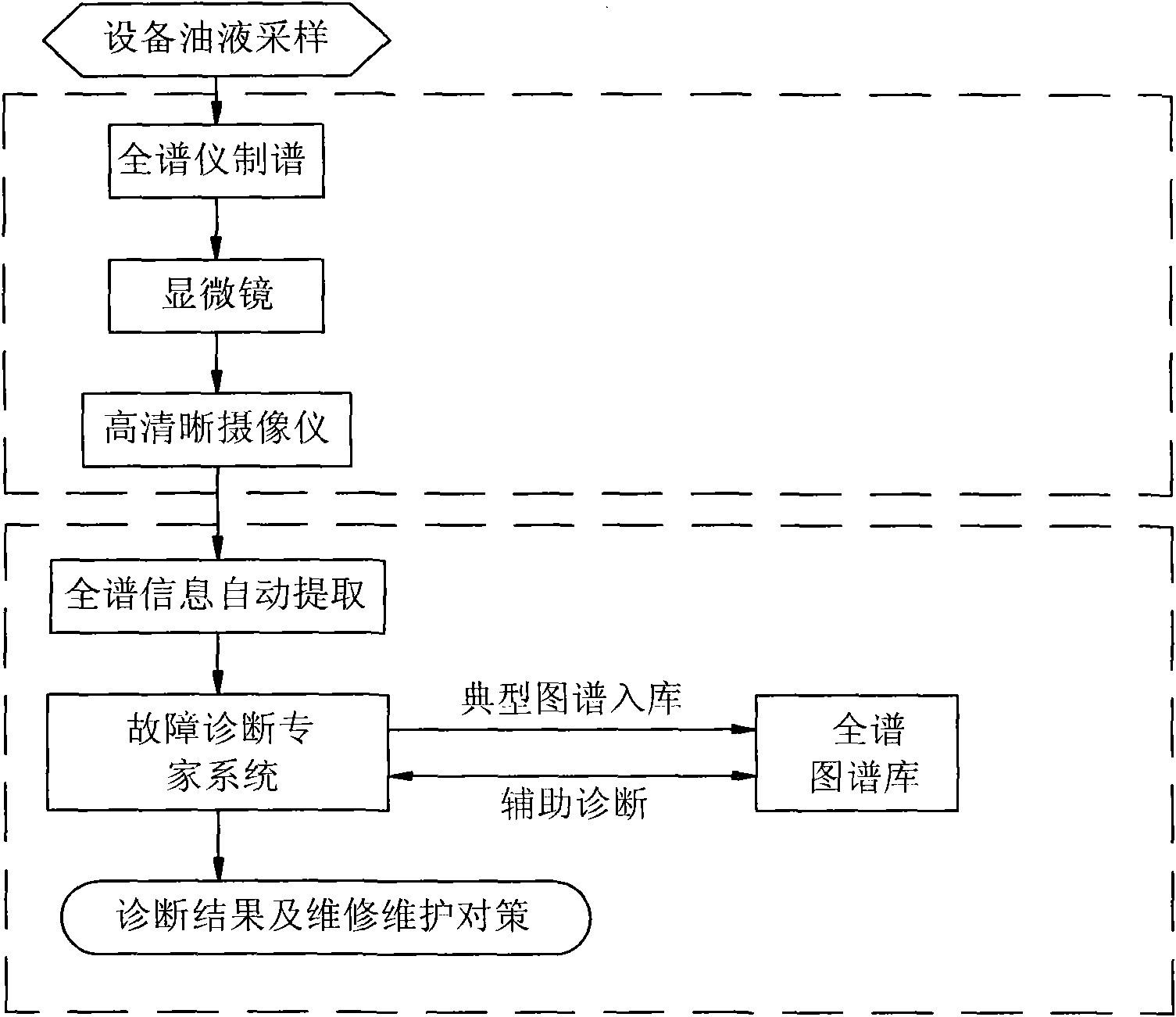

[0016] An oil analysis method for equipment fault diagnosis includes the following steps:

[0017] 1) Arrange the nitrocellulose filter membranes with different filter pore sizes in order from large to small filter pore sizes, and let the oil to be tested flow through the nitrocellulose filter membranes in sequence from the large filter pore to the small filter pore.

[0018] 2) Arrange the nitrocellulose filter membranes on the glass slide 1 in order according to the filter pore size from large to small.

[0019] 3) Dissolving the nitrocellulose filter membrane with an aqueous solution of dimethylformamide, leaving wear particles arranged in a particle size gradient on the slide glass 1 . like figure 1 As shown, according to the size of the filter pore size, as shown in the figure, there are four specifications of nitrocellulose fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com