Blending construction method of blended gravelly soil for dam watertight core

A construction method and core wall technology, applied in dams, barrages, water conservancy projects, etc., can solve the problems of difficult control of mechanical performance indicators, large labor waste, and insufficient supply of materials, so as to achieve convenient mining, increase construction efficiency, and save energy. labor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

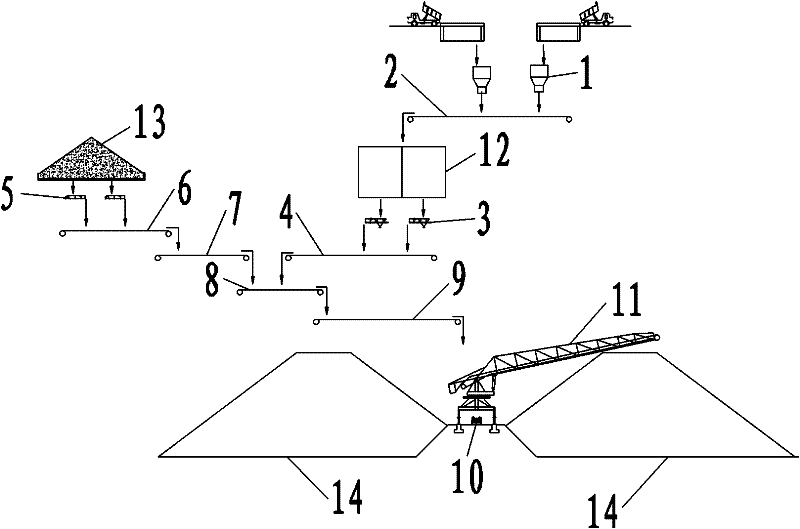

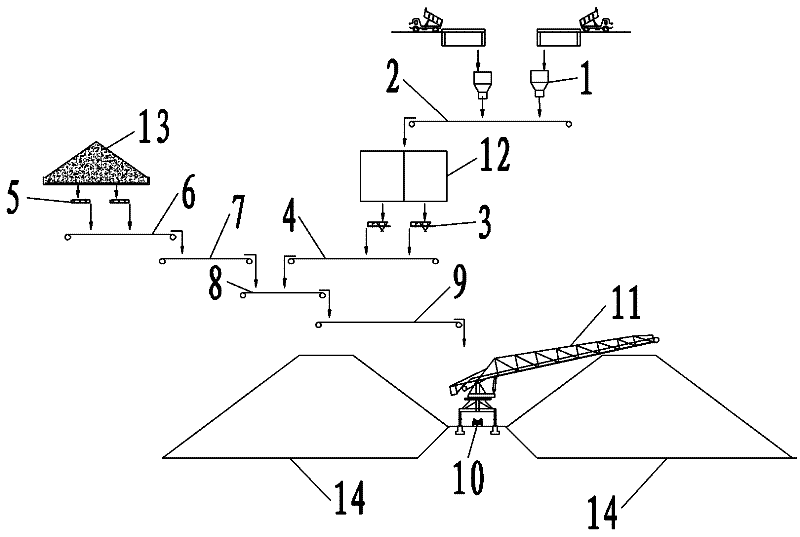

[0016] In the present invention, the mixed gravel soil adopts a belt machine mixing scheme. A dam anti-seepage core wall mixed gravel soil mixing construction method, comprising the following steps:

[0017] 1) The clay material is transported from the soil material yard to the blending yard by car, and after being crushed by the crushing equipment 1 in the material pit, it is sent to the clay material collection hopper 12 by the first belt conveyor 2, and the clay material collection hopper 12 is equipped with a clay material vibration Feeder 3 is supplied to clay material tape machine 4 by clay material vibrating feeder 3, and electronic belt scale is installed on clay material tape machine 4, and is metered to clay material tape machine 4 batching by 65% weight part blending ratio;

[0018] 2) The gravel material is fed to the gravel material belt conveyor (6) by the gravel material vibrating feeder (5) in the gravel material storage yard (13) of the gravel material proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com