Oblique wedge vibration damper for railway freight car bogie

The technology of a vibration damping device and a bogie is applied to the devices, bogies, railway car body parts, etc. that move laterally between the underframe and the bogie, and can solve the problem of unsprung mass overweight, complex structure, and manufacturing and maintenance costs. Advanced problems, to achieve the effect of large anti-rhombic deformation ability, large anti-rhombic stiffness, excellent dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The wedge damping device of the railway freight car bogie of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments:

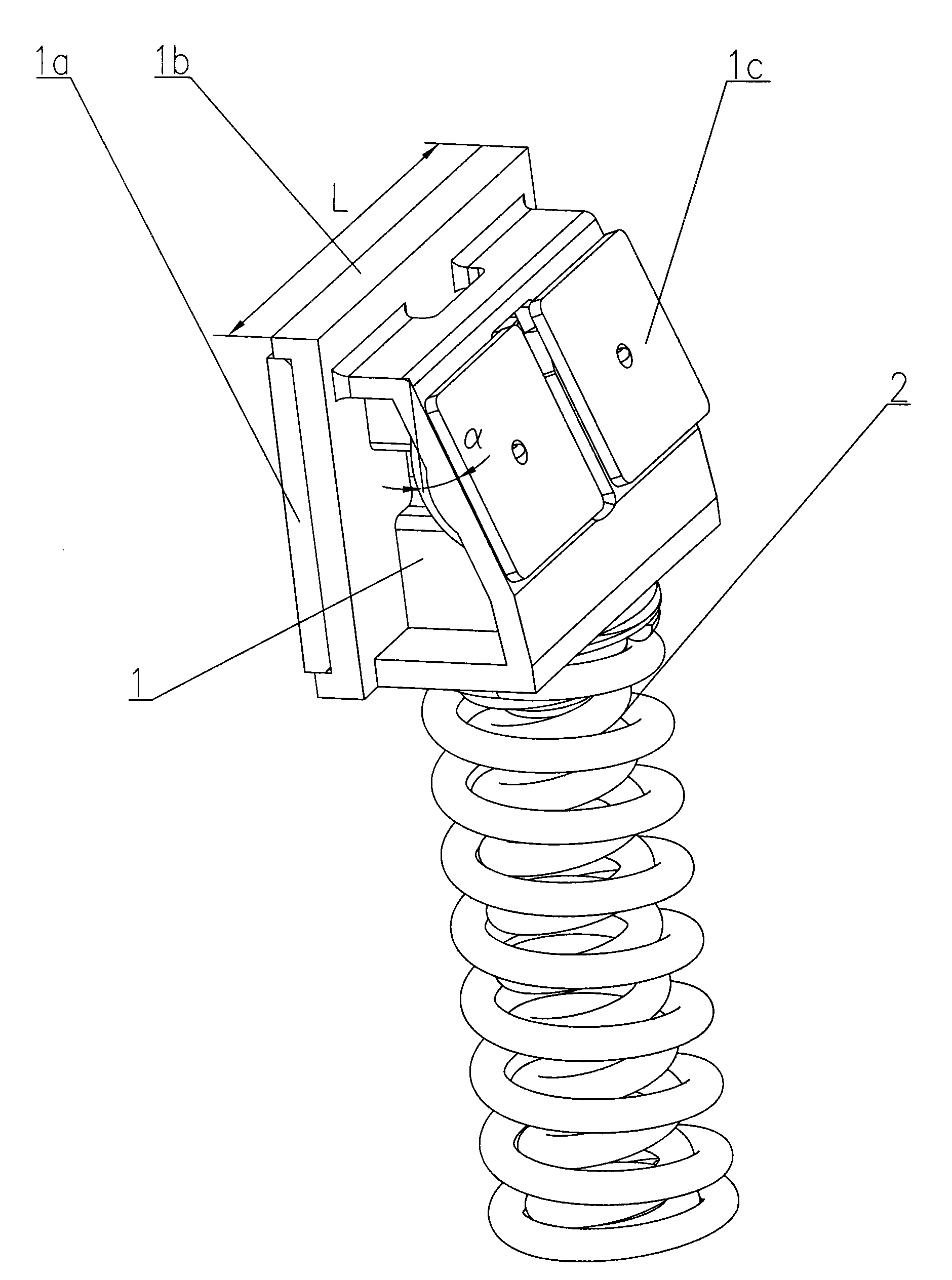

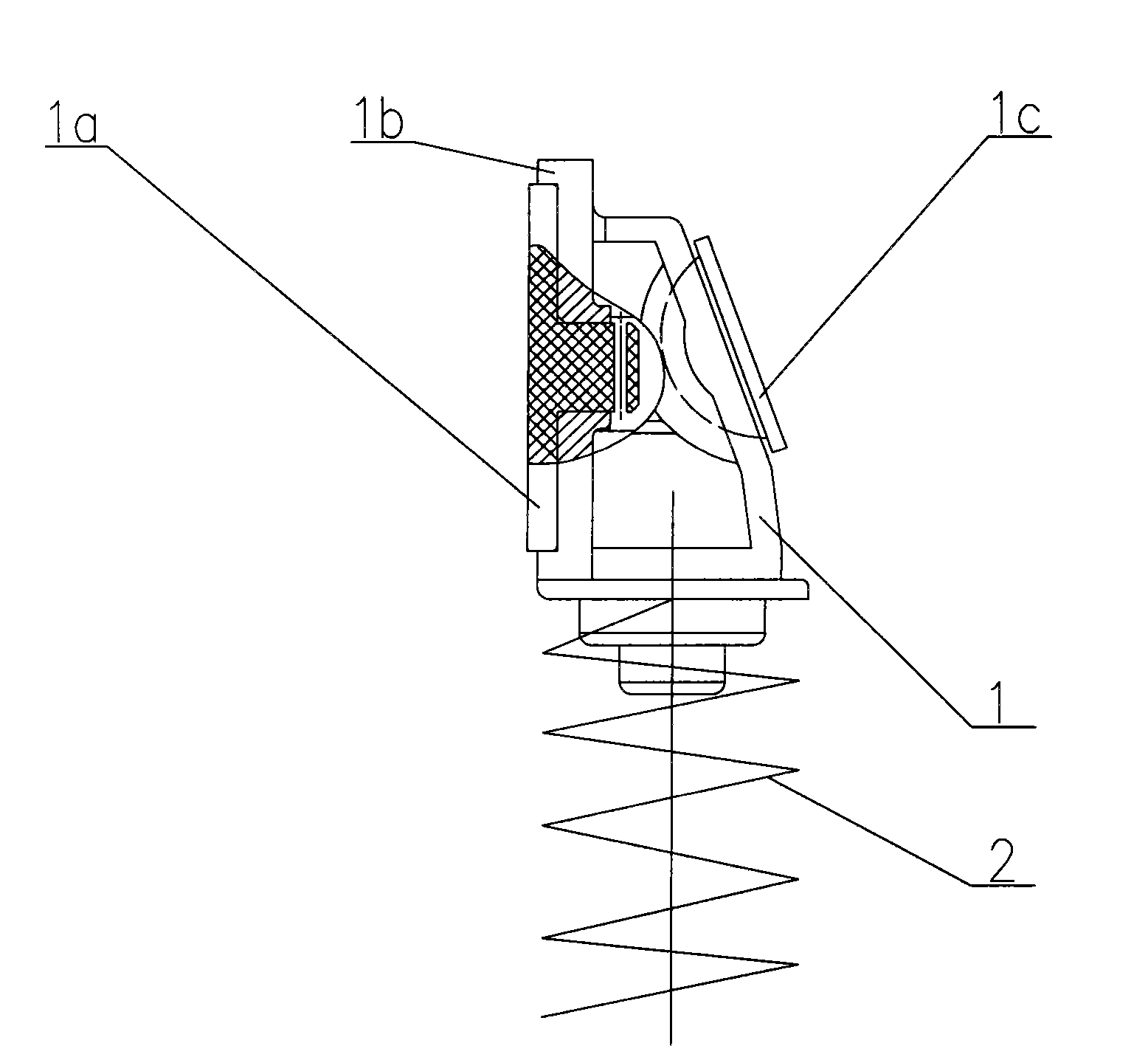

[0018] like figure 1 and figure 2 As shown, the wedge damping device of the railway freight car bogie is mainly composed of a wedge component 1 and a damping spring component 2 installed under the wedge component 1 . The wedge assembly 1 is composed of a wedge body 1b, a primary friction plate 1a arranged on the lateral surface of the wedge body 1b, and a secondary friction block 1c arranged on the inclined surface of the wedge body 1b. The structural design parameters of the wedge composition 1 above satisfy the following mathematical relationship: L=200-260mm, α=16-30°, and μ1 ; Among them, L is the width of the wedge composition 1, α is the angle between the friction surface of the secondary friction block 1c and the vertical surface, μ is the friction coefficient of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com