Automatic welding device and method for welding straight fins on inner wall of long small-bore seamless steel tube

A seamless long steel pipe, automatic welding technology, applied to welding equipment, welding accessories, electrode support devices, etc., to improve the safety of use, save labor costs, and ensure the quality of welds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

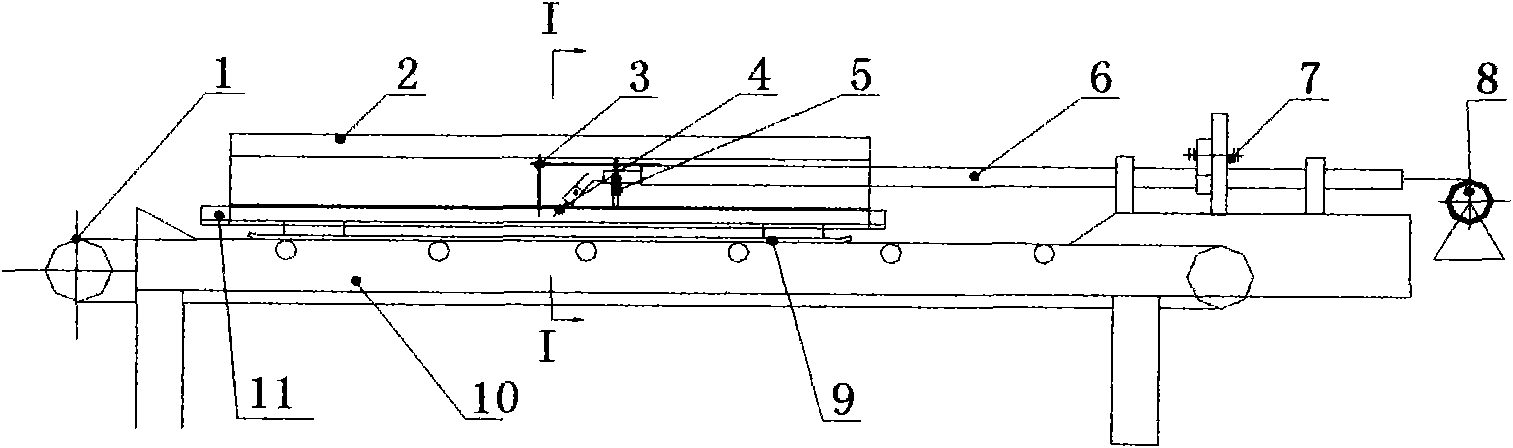

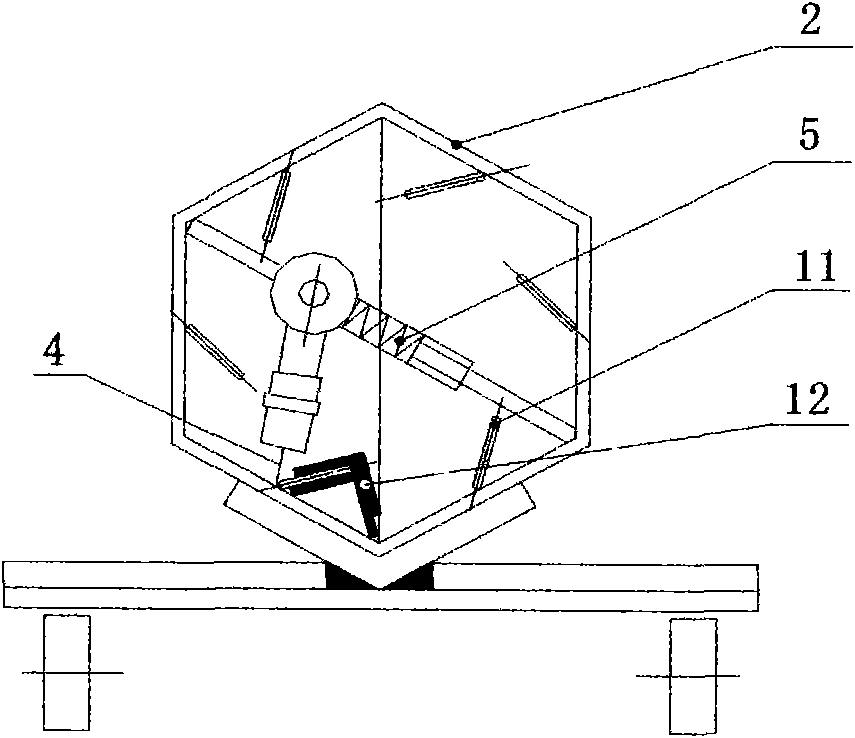

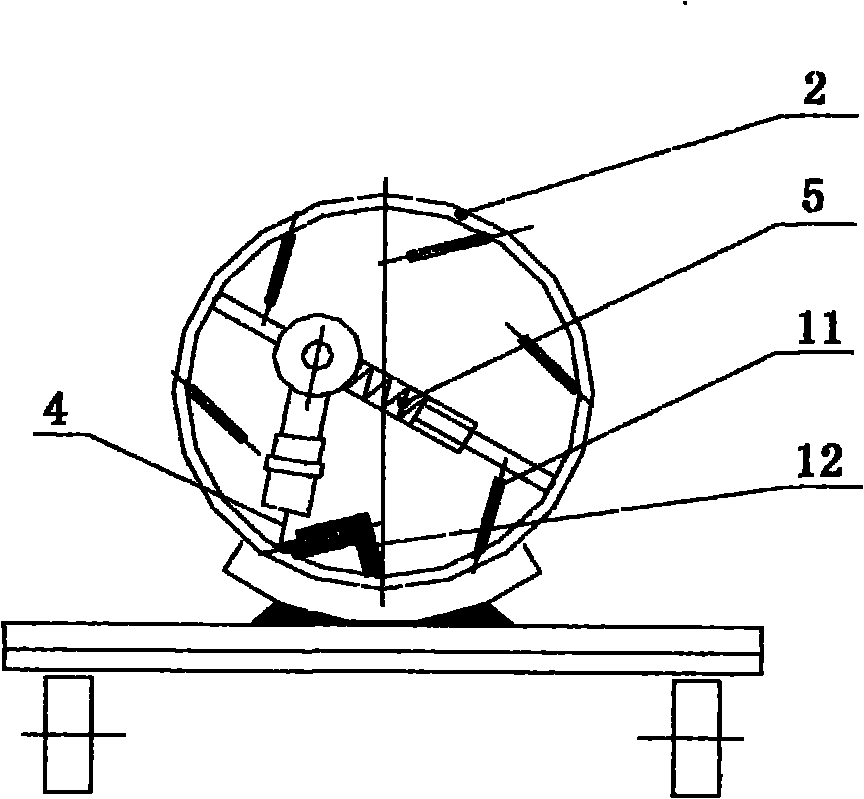

[0038] Such as figure 1 Shown: an automatic welding device for welding straight fins on the inner wall of a small-diameter seamless long steel pipe, characterized in that the device consists of a power control device, a frame 10, a driving device 1, a traveling mechanism 9, a support arm 6 and a support arm 6 is composed of an adjusting device 7, a wire feeding mechanism 8, and a welding torch head 4 with a welding wire spout, wherein:

[0039] The traveling mechanism 9 is installed on the frame 10 and performs reciprocating motion on the frame 10, and the traveling mechanism 9 is driven by the driving device 1;

[0040] A travel switch for controlling the stroke of the traveling mechanism 9 is mounted on the frame 10;

[0041] The adjusting device 7 of the support arm 6 and the support arm 6 is mounted on the frame 10, the welding torch head 4 is mounted on the front end of the support arm 6, and the welding torch head 4 is suspended above the traveling mechanism 9.

[0042...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com