Rectilinear vibrating screen for two groups of split seat-type vibration exciters

A technology of linear vibrating screens and exciters, which is applied in the fields of filtration, solid separation, chemical instruments and methods, etc. It can solve problems such as unstable synchronization of screen machines, torsional vibration of screen machines or changes in projection angle, etc., and achieve self-synchronization The effect is improved, the synchronization effect is good, and the trajectory is stable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

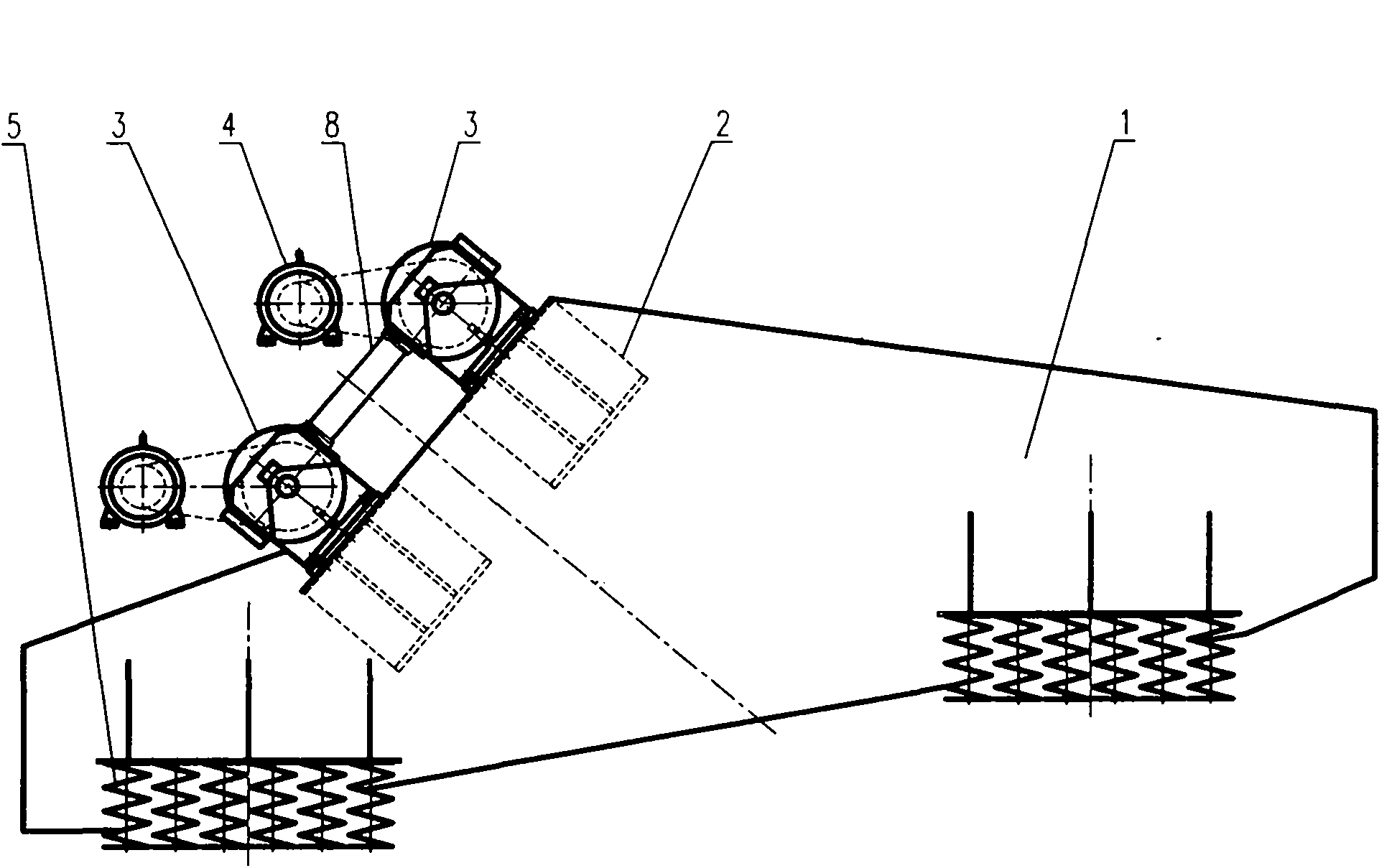

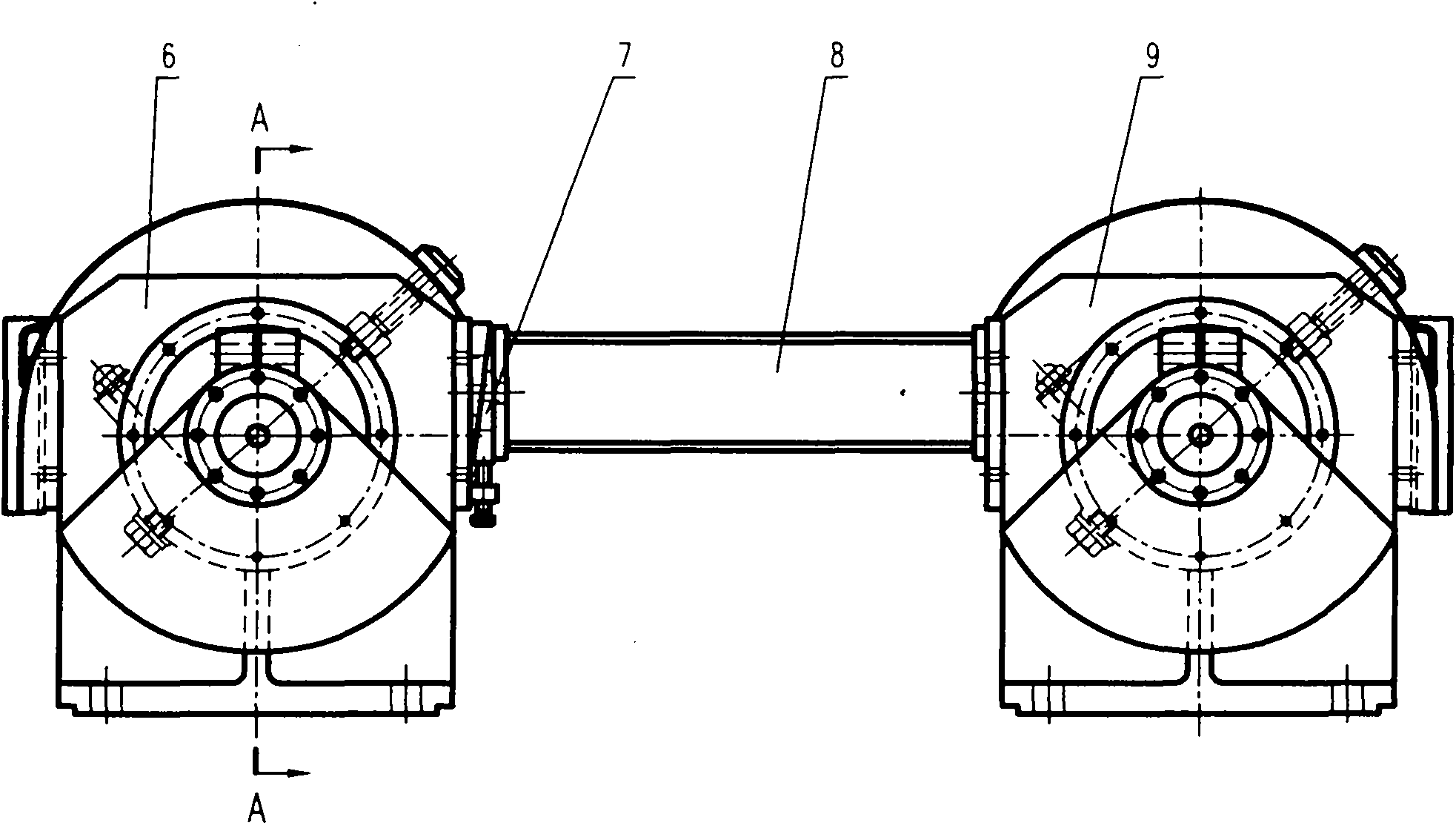

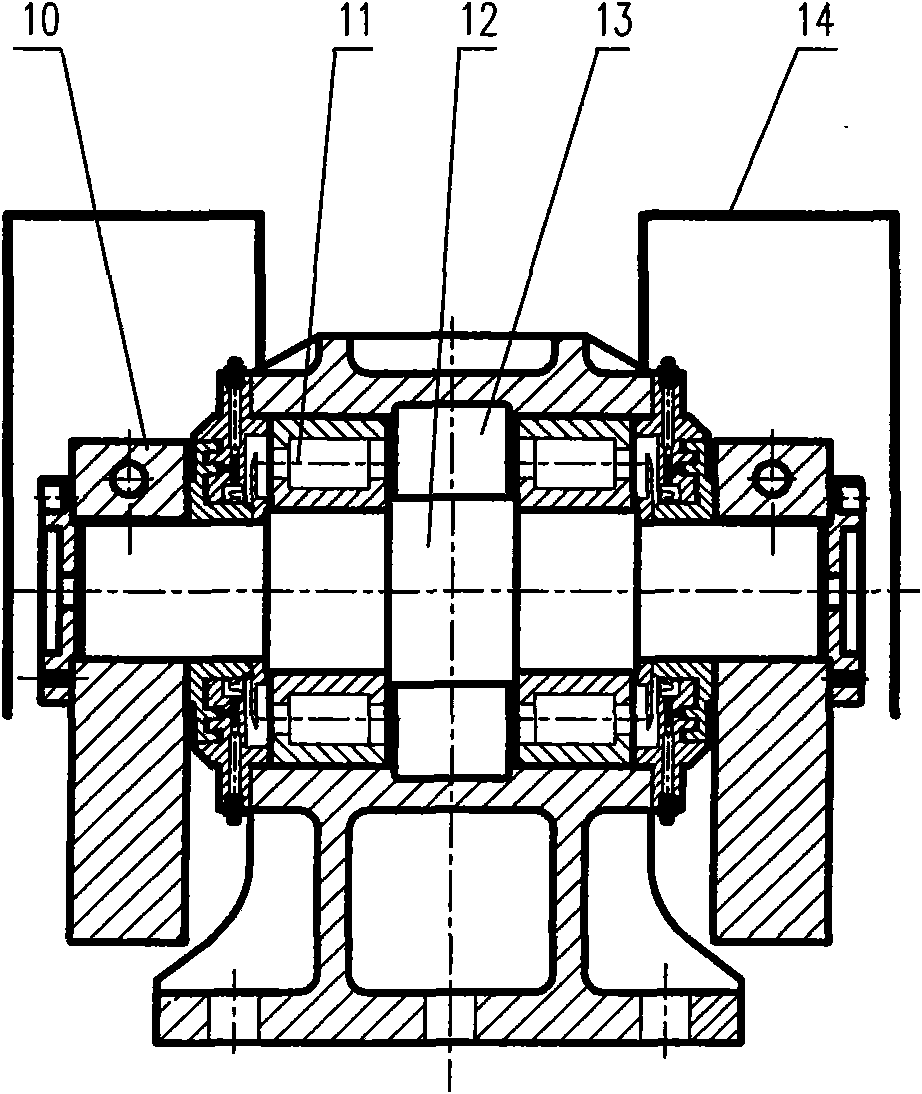

[0009] combined with figure 1 , attached figure 2 And attached image 3 One of the embodiments of the present invention is described: the linear vibrating screen is mainly composed of a screen box 1, a screen surface, a single-shaft seat type vibrator 3, a motor transmission device 4 and a base vibration damping device 5. Two exciter installation beams 2 are arranged on the screen frame of the screen box 1, and each installation beam 2 is respectively equipped with a group of single-axis seat type vibration exciters 3, and each group of single-axis seat type vibration exciters 3 is composed of Four uniaxial seat vibrators are connected in series in the width direction of the screen machine. The main shaft 12 of the uniaxial seat type vibrator 3 is installed on the casing of the vibrator through two bearings 11 , and two eccentric blocks 10 are installed at both ends of the main shaft 12 . The rotation directions of the main shafts 12 of the uniaxial seat type vibrators 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com