Indoor unit for air conditioner

An air conditioner and indoor unit technology, applied in the field of indoor units, can solve the problems of large-scale indoor units and flying out, and achieve the effect of improving air supply performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

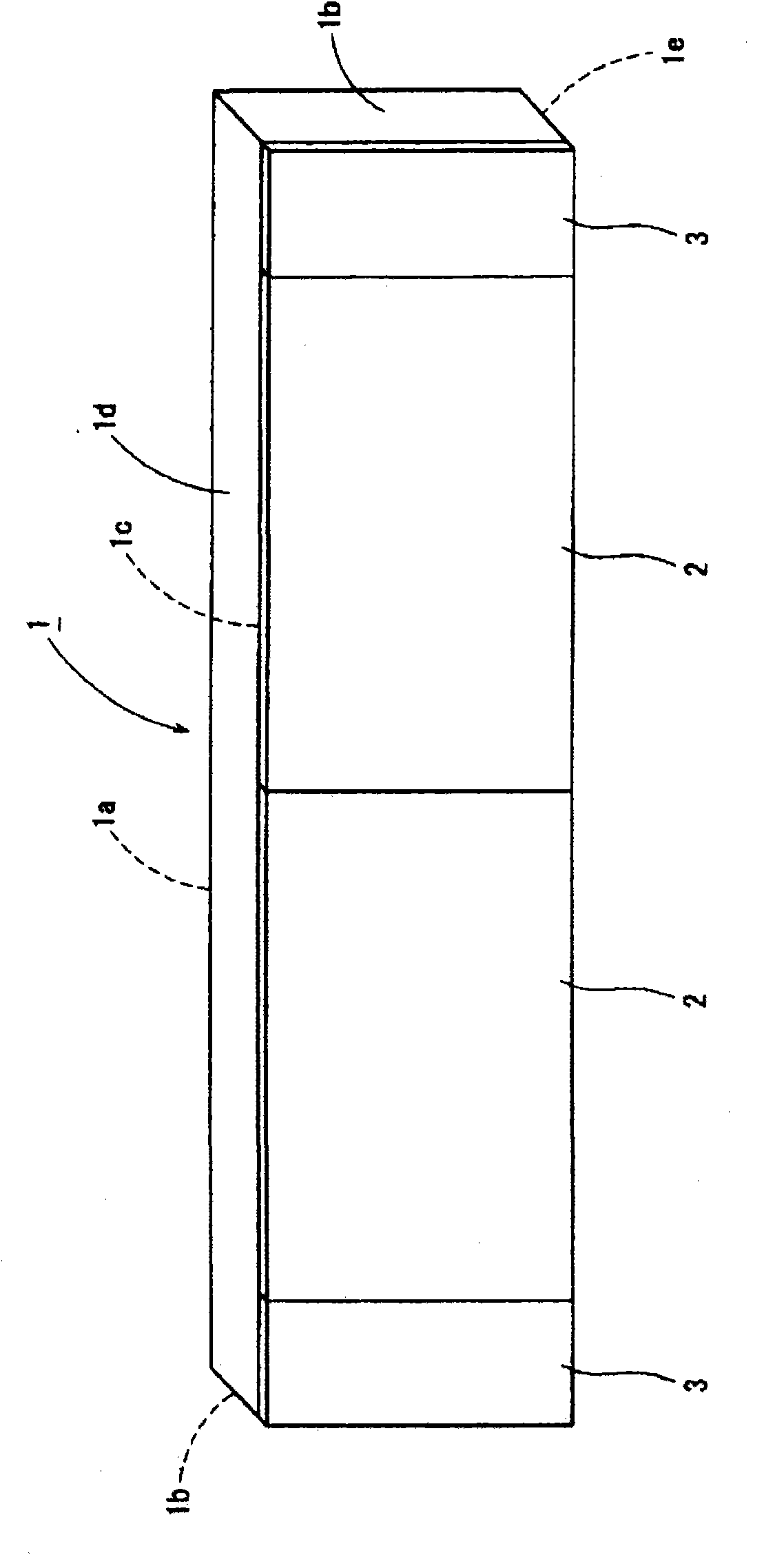

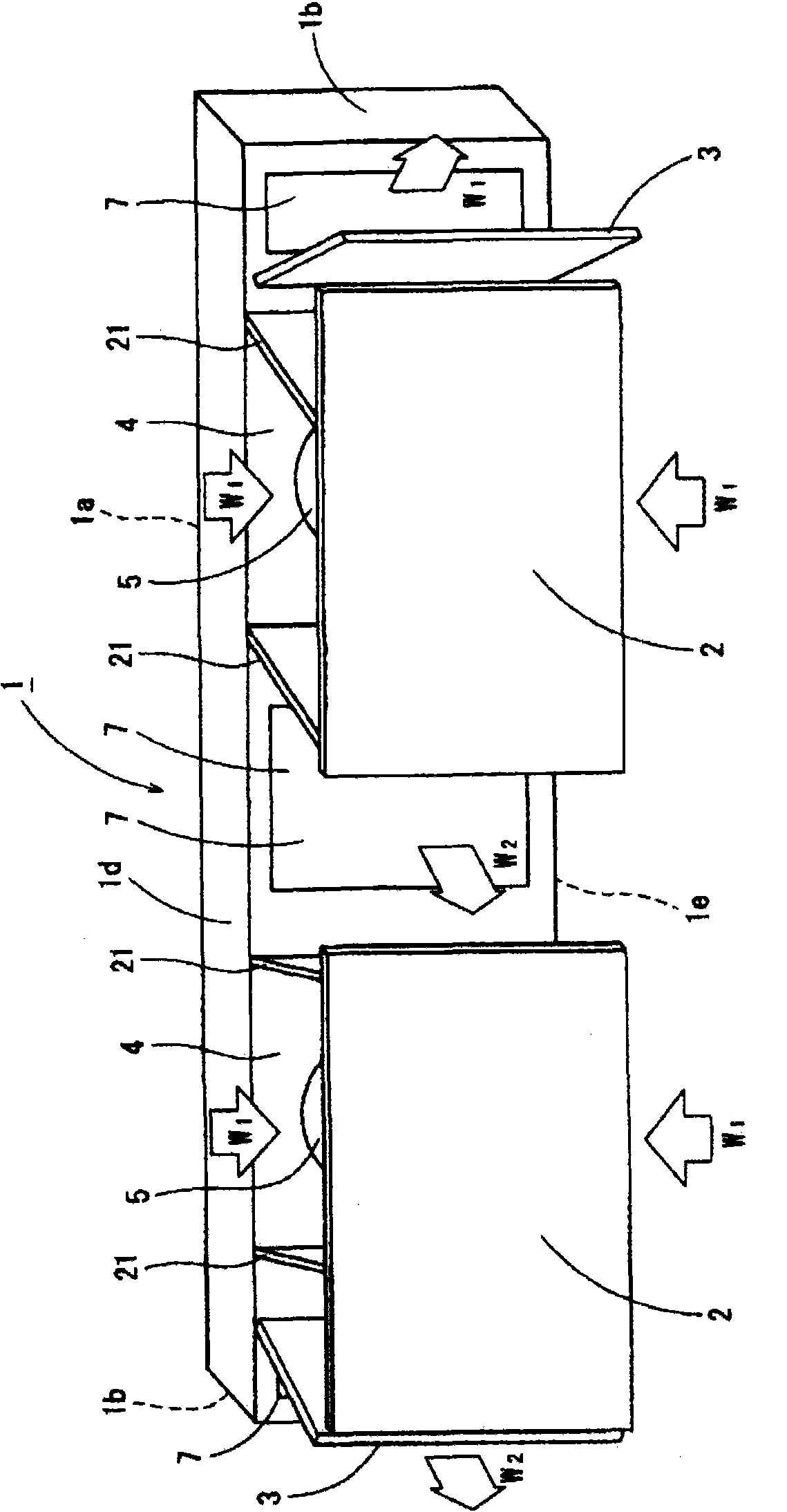

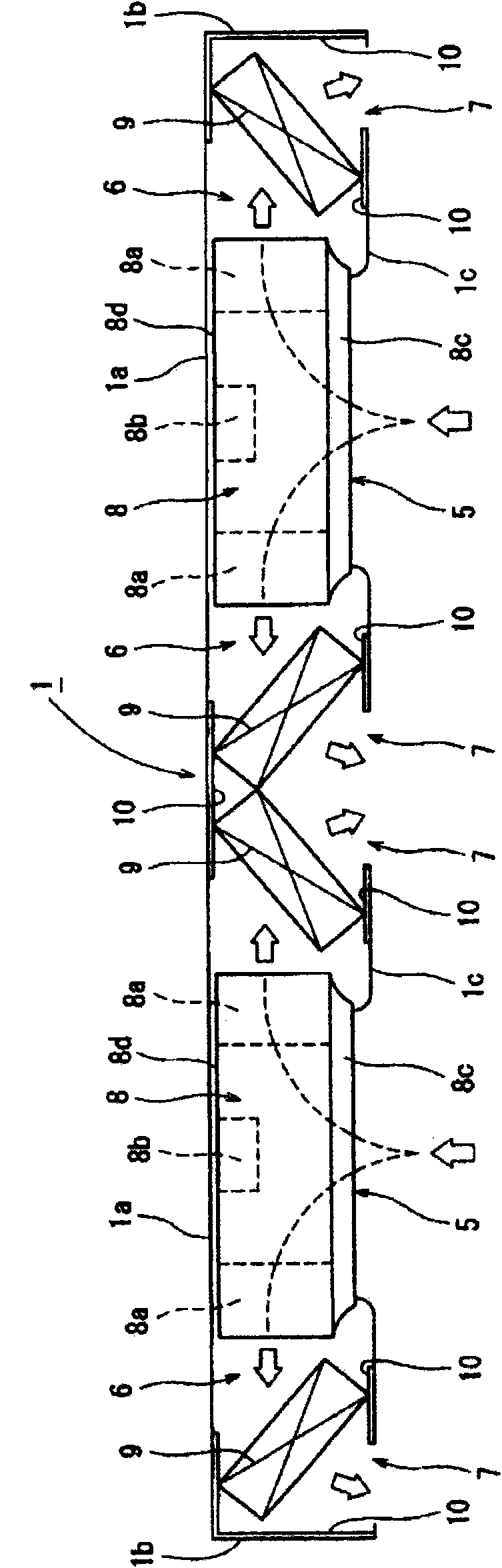

[0051] refer to Figure 1 to Figure 12 , the configuration of the indoor unit for an air conditioner according to the first embodiment of the present invention will be described.

[0052] Such as Figure 1 ~ Figure 3 As shown, the indoor unit for an air conditioner is a twin type composed of a pair of indoor unit units arranged side by side. Each indoor unit is provided with a fan and two heat exchangers arranged on both sides of the fan.

[0053] The indoor unit for an air conditioner is provided with a horizontally long and thin flat box-shaped main body case 1 . The main body case 1 is composed of a rear panel (back panel) 1a, two side panels (side panels) 1b, a front panel (front panel) 1c, an upper panel (top panel) 1d, and a bottom panel (bottom panel) 1e. The back panel 1 a constitutes a mounting surface of a fan motor 8 b of a turbo fan 8 described later.

[0054]Among these panels 1a, 1b, 1c, 1d, and 1e, the panels 1b, 1c, 1d, and 1e other than the rear panel 1a a...

no. 2 approach

[0088] Next, refer to Figure 13 to Figure 16 The configuration of the indoor unit for an air conditioner according to the second embodiment of the present invention will be described.

[0089] The second embodiment differs from the first embodiment in that a step portion 15 b is formed on the drain pan 15 . Specifically, the positioning members 24 and 25 for setting the inclination angle are arranged in the drain pan 15, and the lower part of the drain pan 15 is formed with, for example, Figure 13 ~ Figure 15 The step portion 15b shown. The upper surface of the stepped portion 15b functions as a positioning member in the height direction. Step portion 15 b is formed by a wide portion at the top of drain pan 15 and a narrow portion at the bottom of drain pan 15 . On the other hand, on the outer surface of the narrow portion of the stepped portion 15b (the outer surface of the bottom of the drain pan 15), for example, Figure 16 The vacuum insulation material 10 whose thic...

no. 3 approach

[0094] Next, refer to Figure 18 ~ Figure 20 , the configuration of the indoor unit for an air conditioner according to the third embodiment of the present invention will be described.

[0095] The third embodiment is characterized in that the subcooling heat exchanger 19 having the structure of the above-mentioned first embodiment is changed from a cylindrical heat exchanger with spine fins to, for example, Figure 18 ~ Figure 20 A flat cross-fin coil subcooling heat exchanger 19 is shown.

[0096] With such a configuration, it is possible to further improve the heat exchange efficiency during supercooling.

[0097] Specifically, the cross-fin coil type subcooling heat exchanger 19 has a much thinner thickness than the above-mentioned ridge-fin type subcooling heat exchanger. Therefore, the space problem can be solved naturally, and the pressure loss of the turbofan 8 is low, and the heat exchange capacity increases by more than 50% under the same ventilation resistance val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com