Connector device for trough pans on mining equipment trough pan and assembly component for the same

A technology for connecting device and mining equipment, applied in the direction of connection, earth-moving drilling, cutting machinery, etc., can solve the problems of troublesome, difficult and time-consuming bolt removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

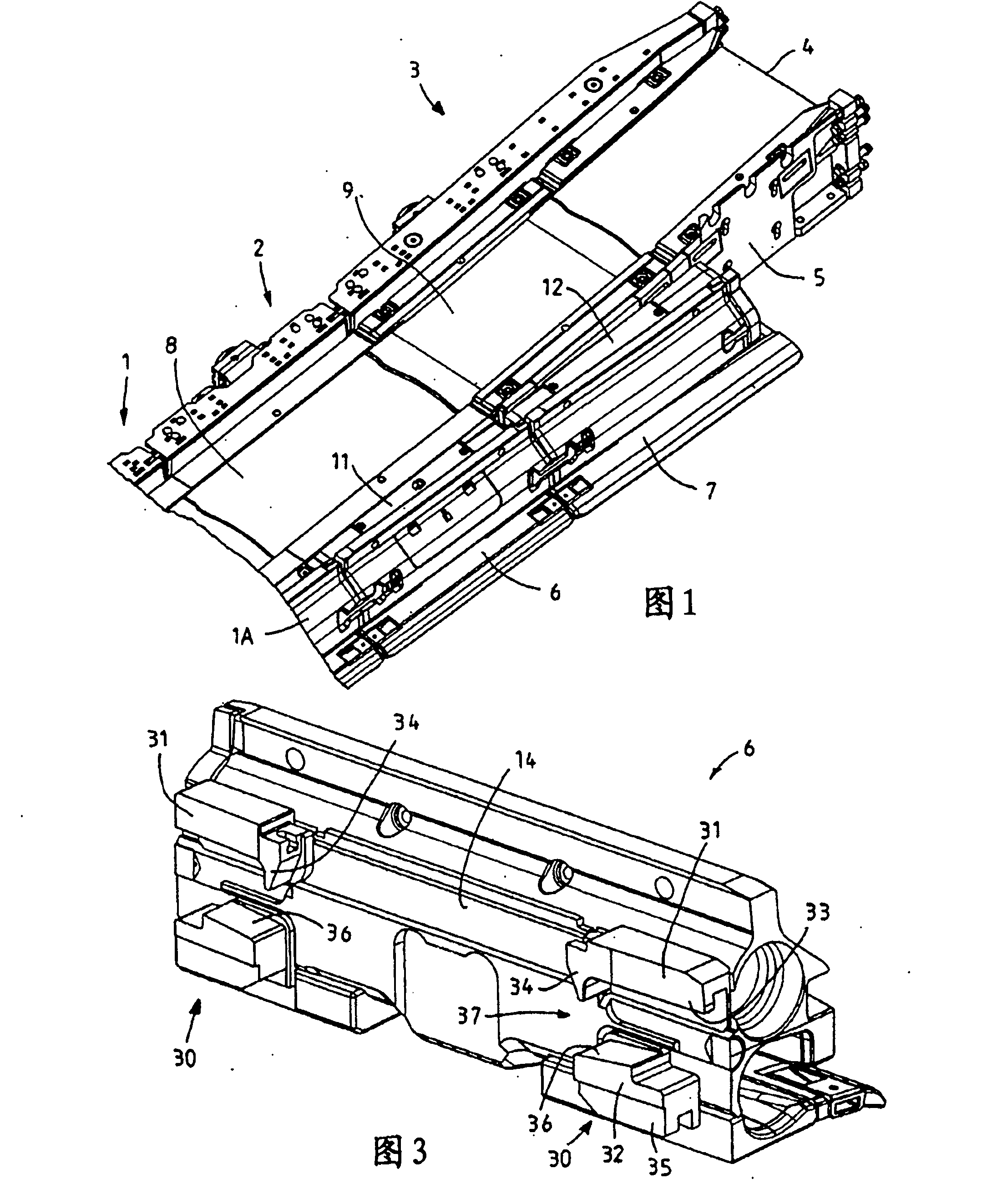

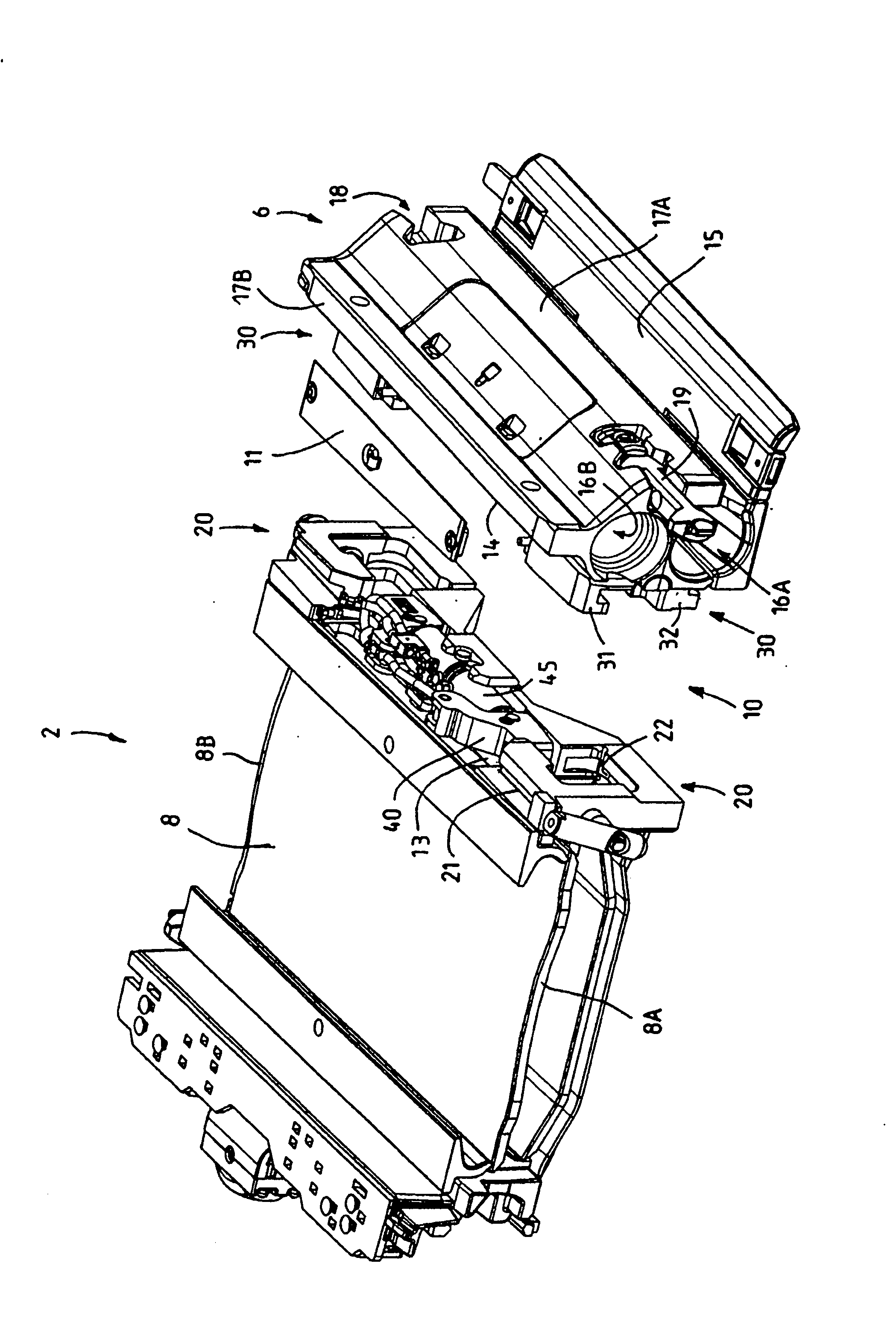

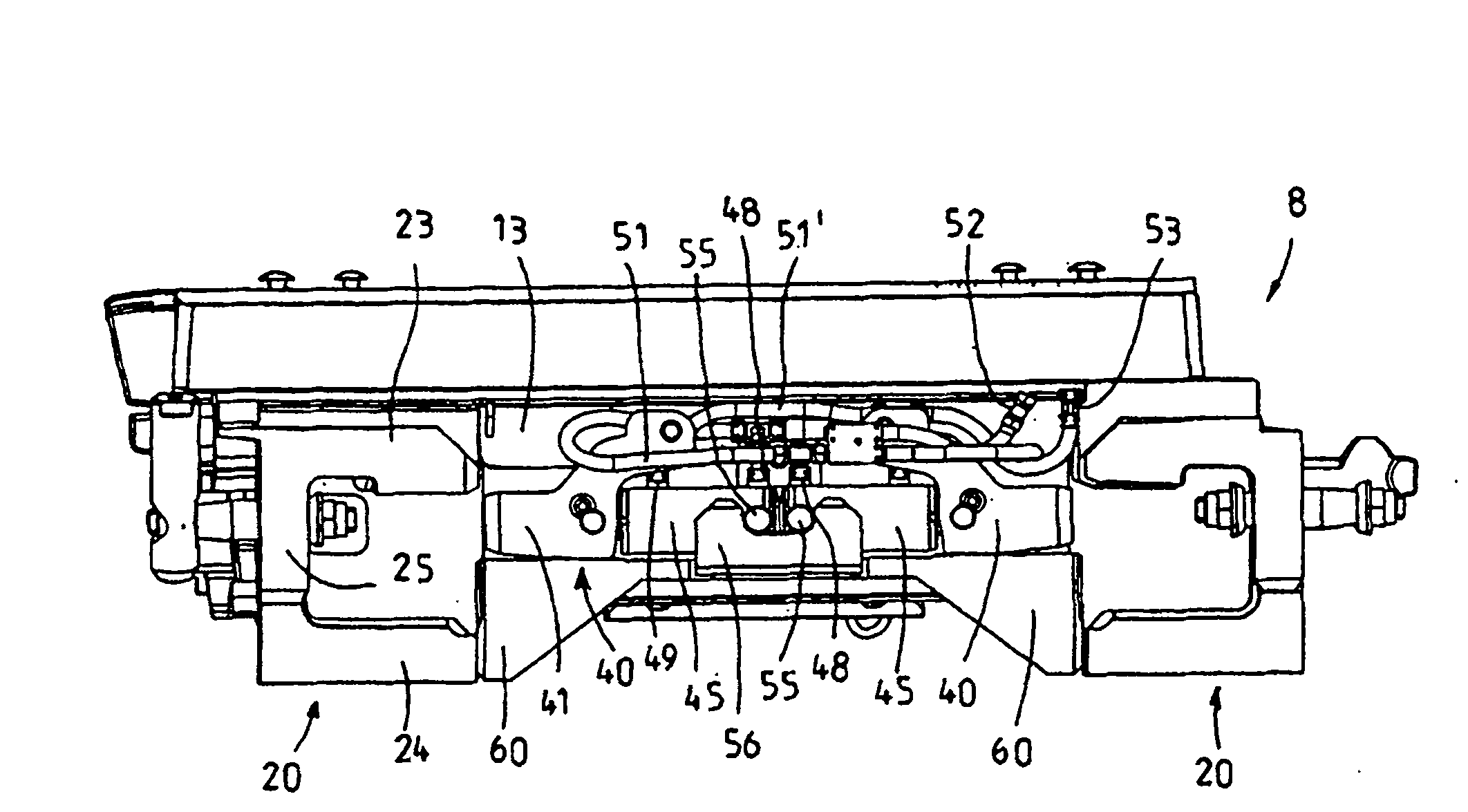

[0020] exist figure 1 A conventional chute 1, a wedge-shaped chute 2 and a connecting chute 3 in a mining equipment that does not show other structures in detail are shown in the figure. On the head 4 of the connecting chute 3, a frame can be connected in a known manner. The frame has sprockets for a conveyor chain (not shown) and a plow chain (not shown) for moving a mining plow, also not shown, as a mining machine. At the same time, before the conveyor chain plate is conveyed to the frame through the connecting chute 3, the three shown chutes 1, 2, 3 just form a belt consisting of one or more conventional chutes 1 arranged in the working face. Transition region or end region of the conveying chute with connected planer guides, in which several wedge-shaped chutes 2 can also be arranged. As is known to those skilled in the art in underground mining, a plow end stop can be mounted on the connection chute 3, for example on the connection bracket 5, so that the mining plow does...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com