Energy-saving transformer

A technology of energy-saving transformers and step-up transformers, applied in the field of transformers, can solve the problems of transformers with huge electric energy, large power loss, and energy waste, and achieve the effects of reducing eddy current loss, reducing heat loss, and being easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

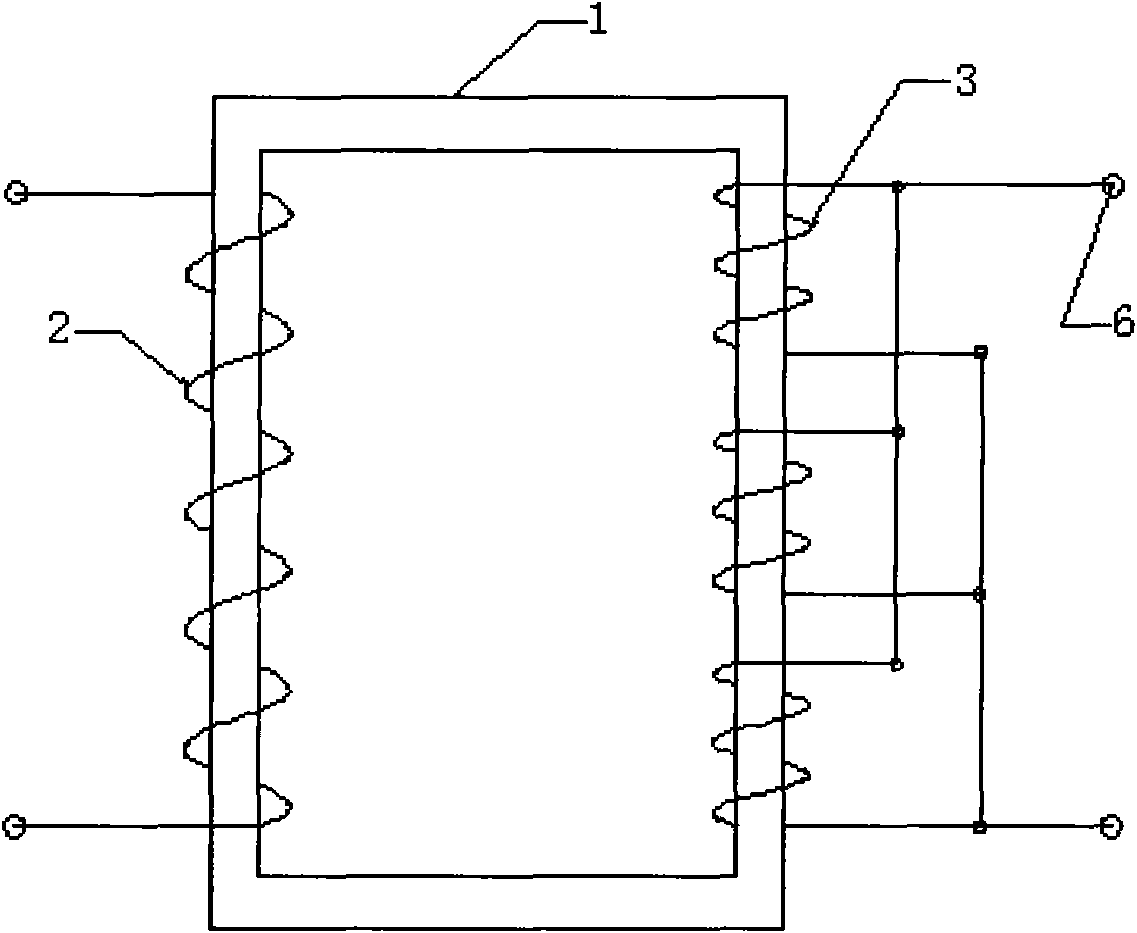

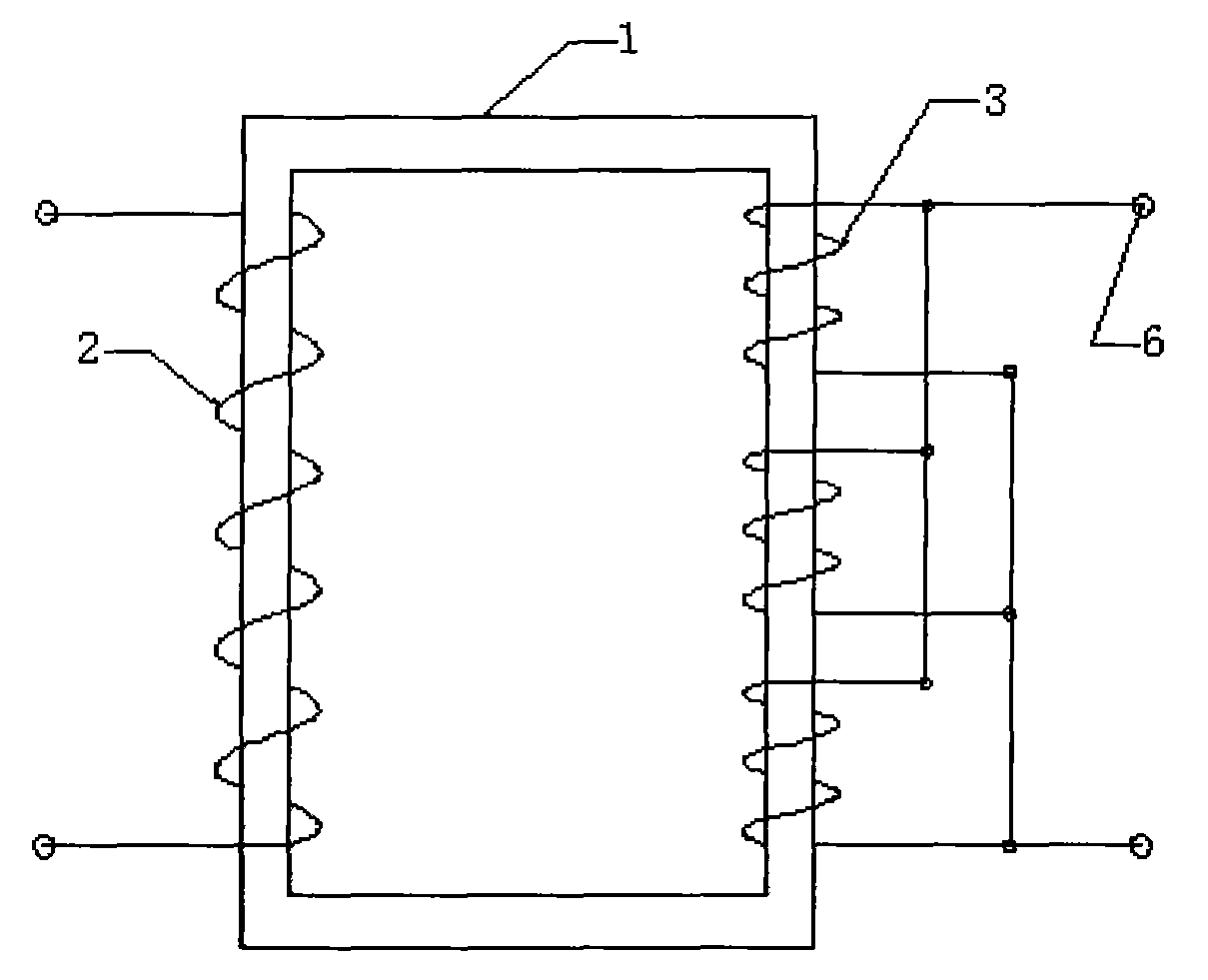

[0013] figure 1 Among them, the energy-saving step-down transformer includes a magnetic core 1, a primary coil 2 and a secondary coil 3, and is characterized in that: the number of coils in the secondary coil 3 of the step-down transformer is multiple, and the resistance value of each coil is equal, more After the two coils are connected in parallel, the terminal 6 is drawn out, and the heat loss of the transformer is inversely proportional to the number of coils of the secondary coil 3 of the step-down transformer.

[0014] The energy-saving step-down transformer has a constant rated output voltage and a rated output current of I 2 , the primary coil 2 of the step-down transformer remains unchanged, assuming that the resistance value of the secondary coil of the original step-down transformer is r, the number of coils of the secondary coil 3 of the step-down transformer of the invention is n, and the resistance value of each coil is R , the resistance value after n coils are...

Embodiment 2

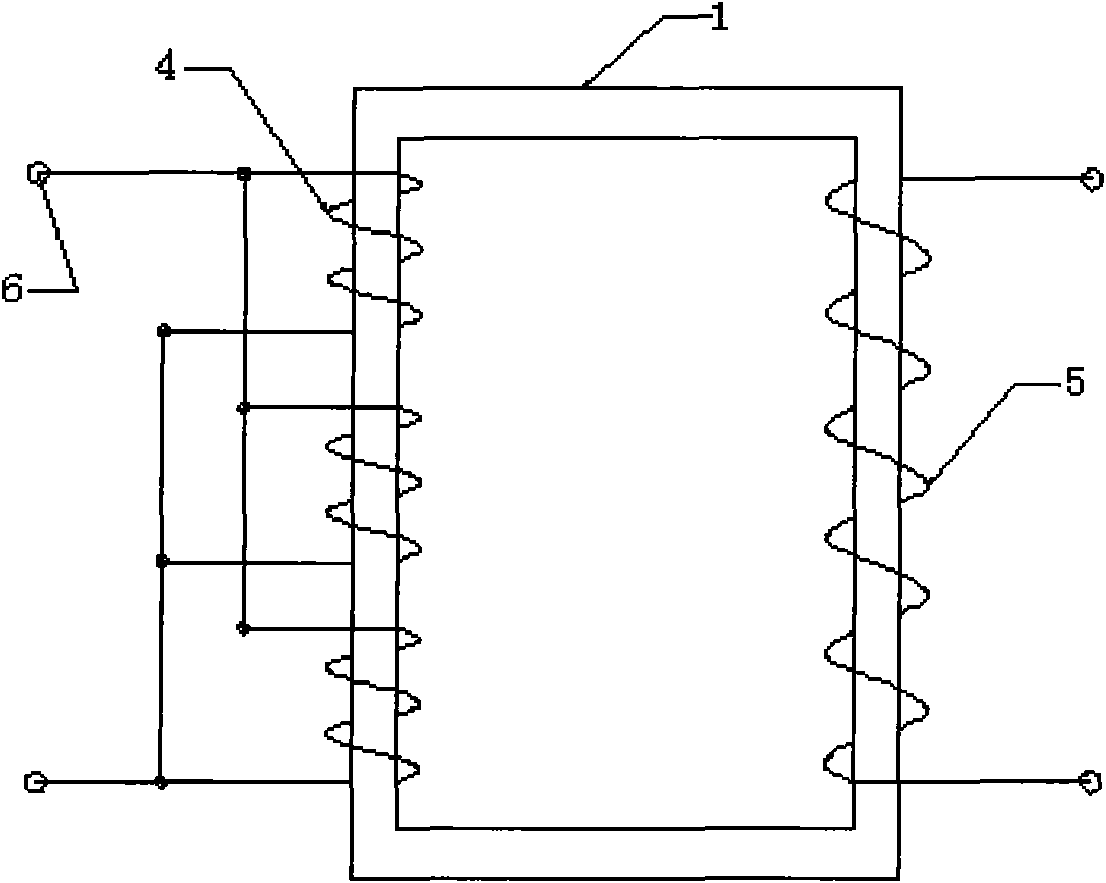

[0019] figure 2 Among them, the energy-saving step-up transformer includes a magnetic core 1, a primary coil and a secondary coil. After the connection, the terminal 6 is drawn out, and the heat loss of the transformer is inversely proportional to the number of coils of the primary coil 4 of the step-up transformer.

[0020] The energy-saving step-up transformer has a constant rated input voltage and a rated input current of I 1 , the secondary coil 5 of the step-up transformer remains unchanged, assuming that the resistance value of the primary coil of the original step-up transformer is r, the number of coils of the primary coil 4 of the step-up transformer of the invention is n, and the resistance value of each coil is R, The resistance value after n coils are connected in parallel is R / n, and the heat loss of the existing transformer is The heat loss of the energy-saving step-up transformer of this invention is

[0021] 1) If R=r, then the heat loss of the energy-sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com