Inversely-constructed underground continues wall with siamesed reinforcing cage

An underground continuous wall and steel cage technology, which is applied in sheet pile walls, foundation structure engineering, excavation, etc., can solve the problems of long construction period, high cost, and prone to voids, etc., and achieve the effect of reducing construction costs and improving project progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0039] The specific implementation, non-limiting examples are as follows:

Embodiment

[0040] Example: see Figure 2A to Figure 4 , the underground diaphragm wall of the present invention adopts the reverse construction method, and the formed underground diaphragm wall has a conjoined reinforcement cage, and its construction process is carried out as follows:

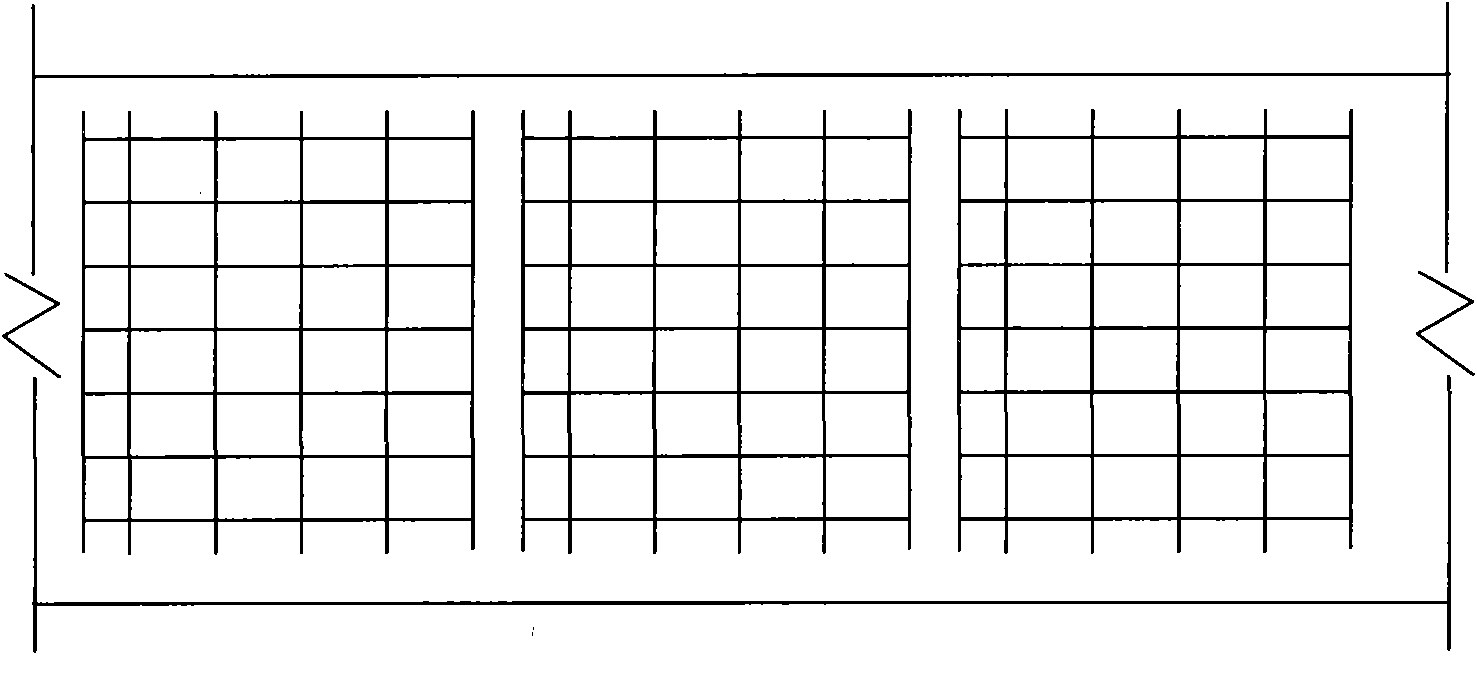

[0041] ①. Delineate the width area of the underground diaphragm wall to be built on the ground, Figure 4 The width area of the diaphragm wall is indicated, and the area surrounded by the diaphragm wall is where the building to be built is located. After the diaphragm wall is formed, a deep foundation pit needs to be dug in this area;

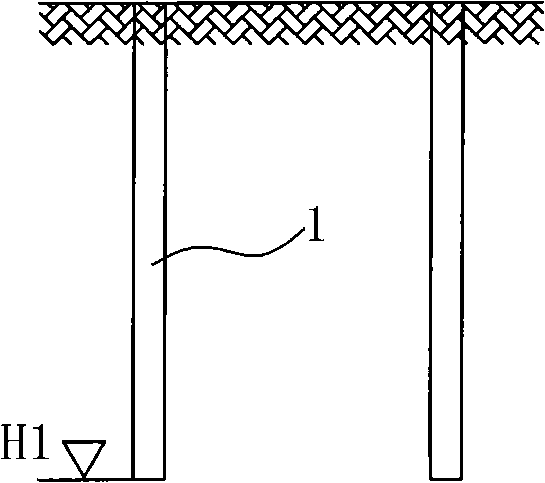

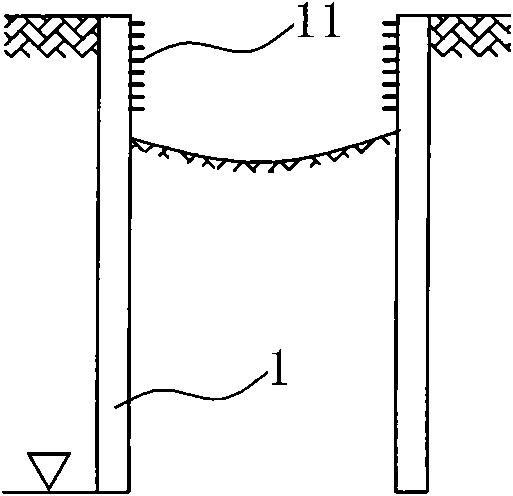

[0042] ②, image 3 As shown, prepare the prefabricated pile 1, the two sides of the upper half or the upper 2 / 3 section of the pile body (depending on the depth ratio of the depth of the foundation pit and the bearing layer) are provided with pre-embedded ribs 11 protruding from the pile body, and the The pre-embedded reinforcement is bent and attached to the two sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com