Machining method of long-rod motor stand

A processing method and a technology of a motor frame, applied in metal processing equipment, manufacturing tools, boring/drilling, etc., can solve problems such as inconvenient processing, and achieve the effects of convenient processing, easy machine tool equipment, and easy product quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

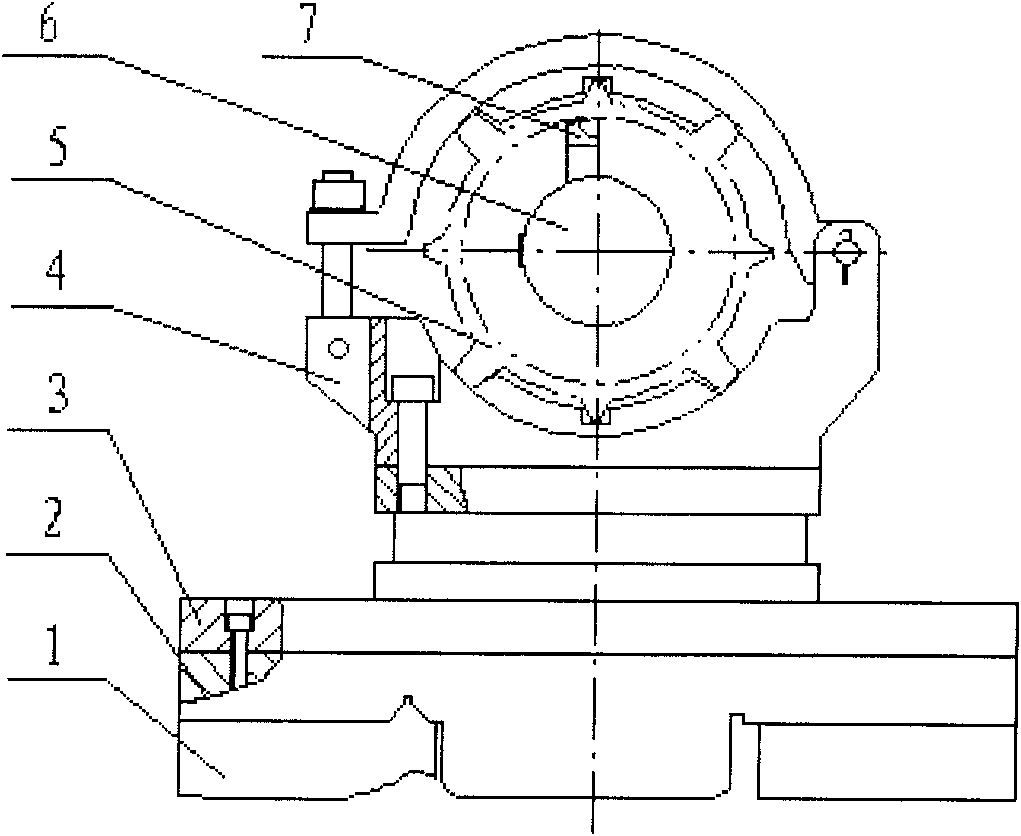

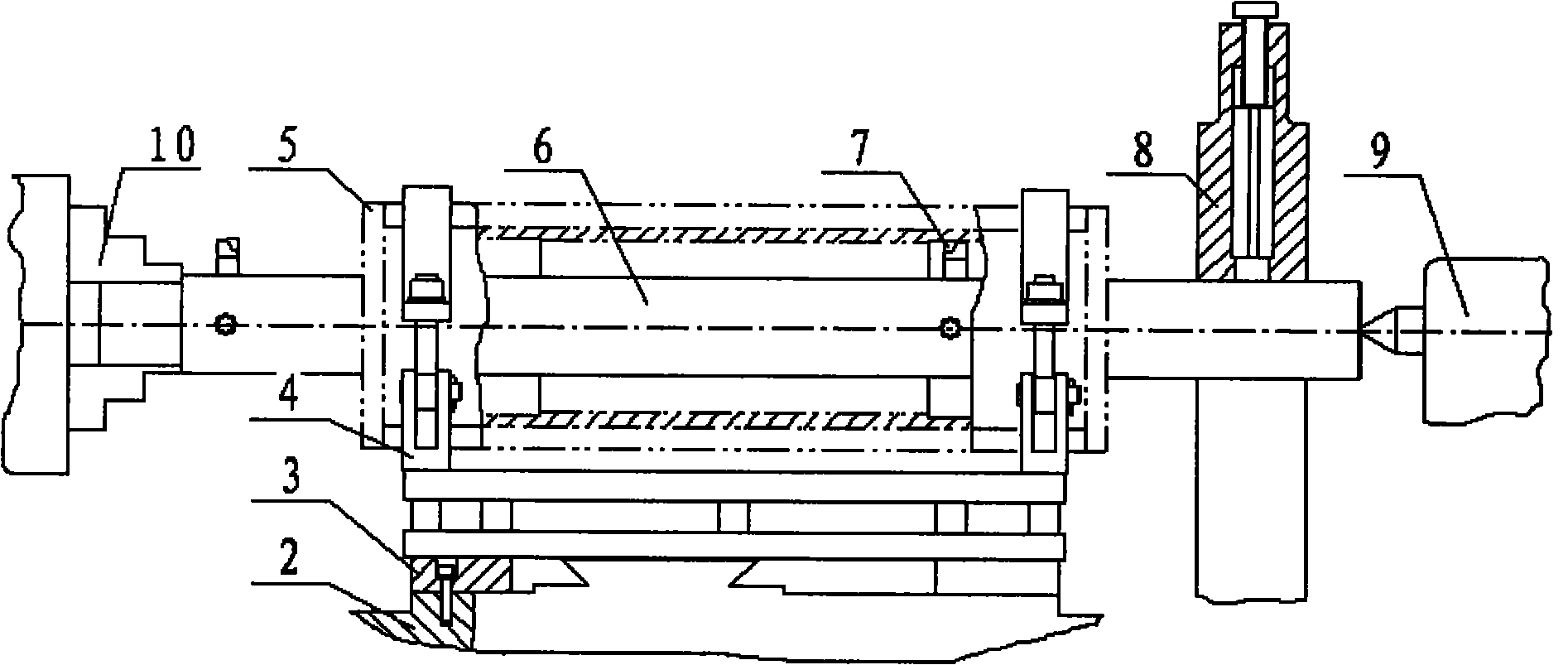

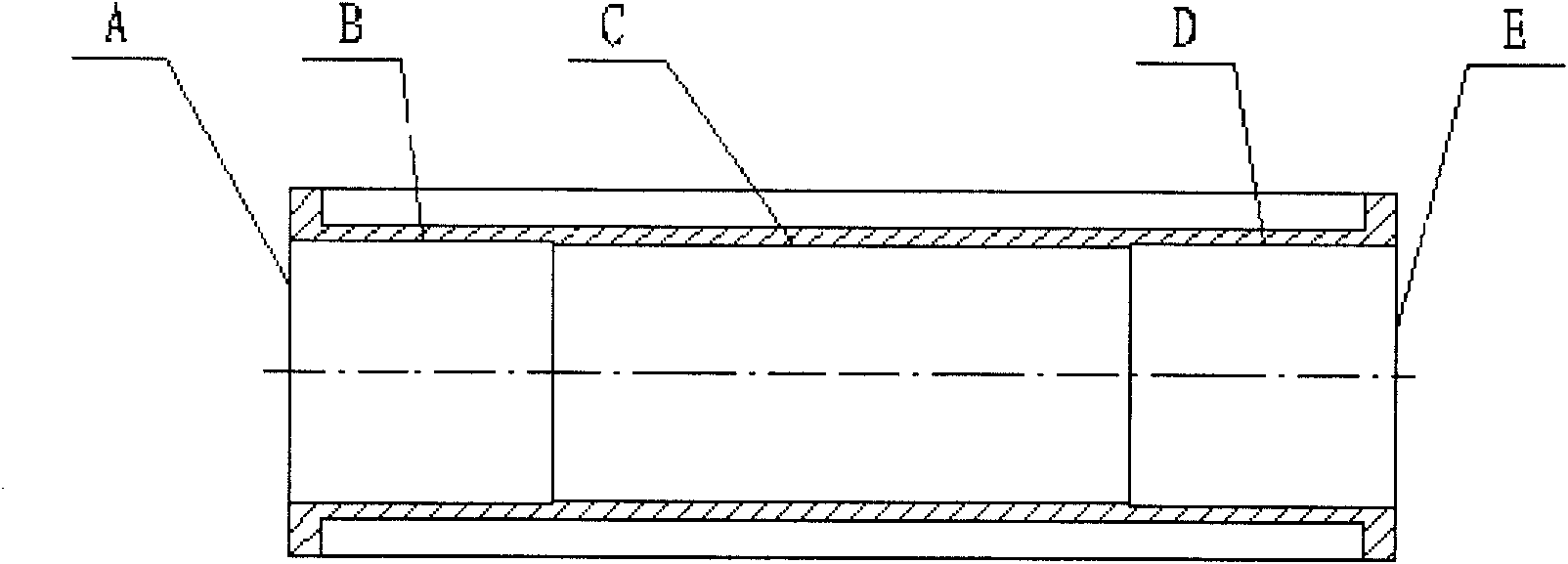

[0029] The processing method of the long rod motor casing provided by the present invention is a processing method that changes turning into boring, specifically: see figure 1 , figure 2 , remove the middle carriage on the horizontal lathe, fix the special workbench 3 on the large carriage 2 of the horizontal lathe by bolts, fix the clamping fixture 4 on the special workbench 3 by bolts, and finally fix the machine base The clamping of the pressing fixture is firm, and the longitudinal movement of the large carriage 2 and the rotational movement of the main shaft of the lathe are used to realize the machining of the inner hole of the long rod motor base in one clamping.

[0030] The method of the present invention will be further described below by taking the machining of the inner hole of the VLB motor base as an example.

[0031] The method is to utilize a horizontal lathe (model is CW6180) to carry out boring to realize the inner hole processing of the VLB type motor supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com