Efficient high-strength composite drill bit

A composite drill bit, high-strength technology, used in construction and other directions, can solve the problems of cutting edge wear, blade wear and tear, affecting the construction quality of underground diaphragm walls, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

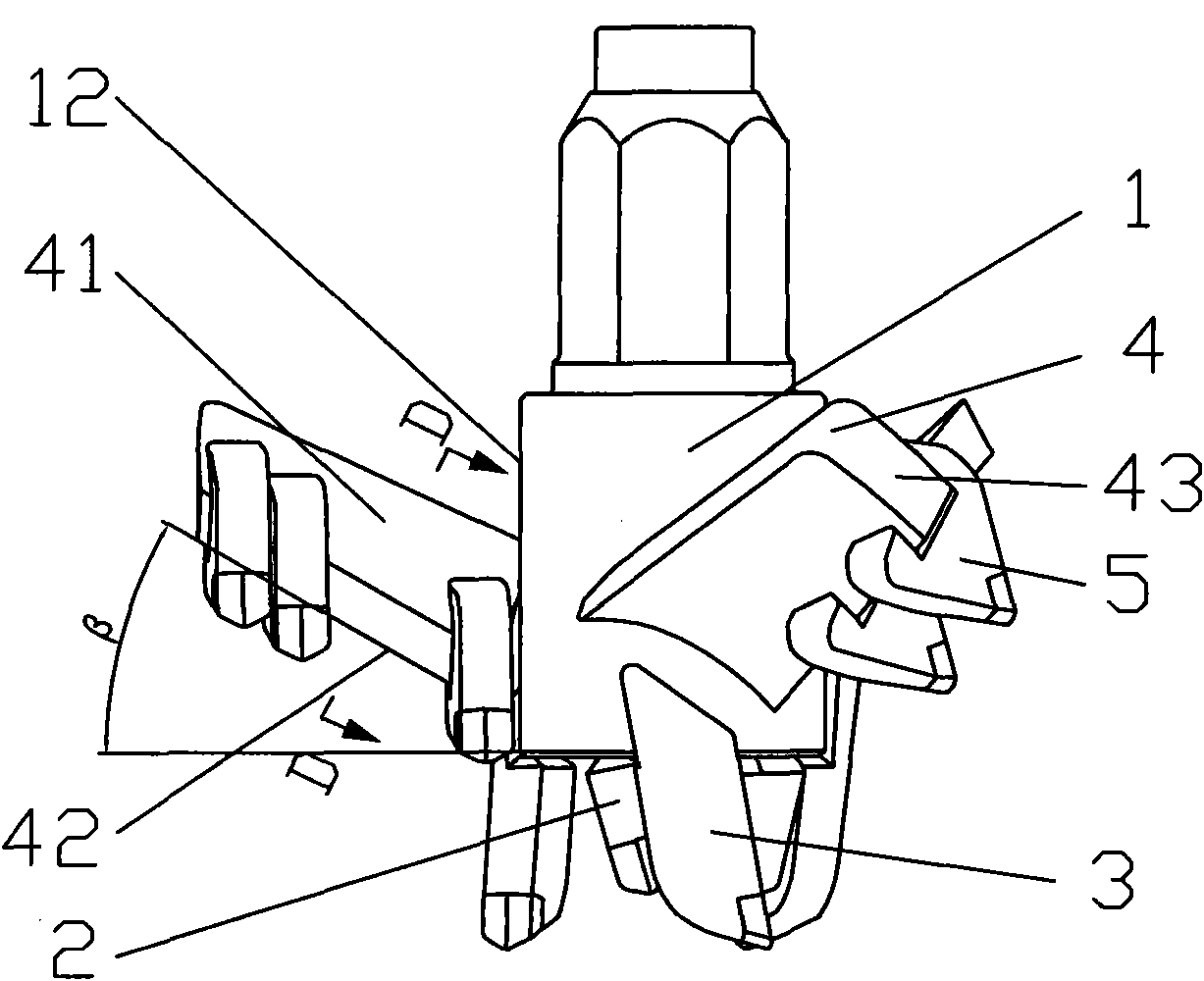

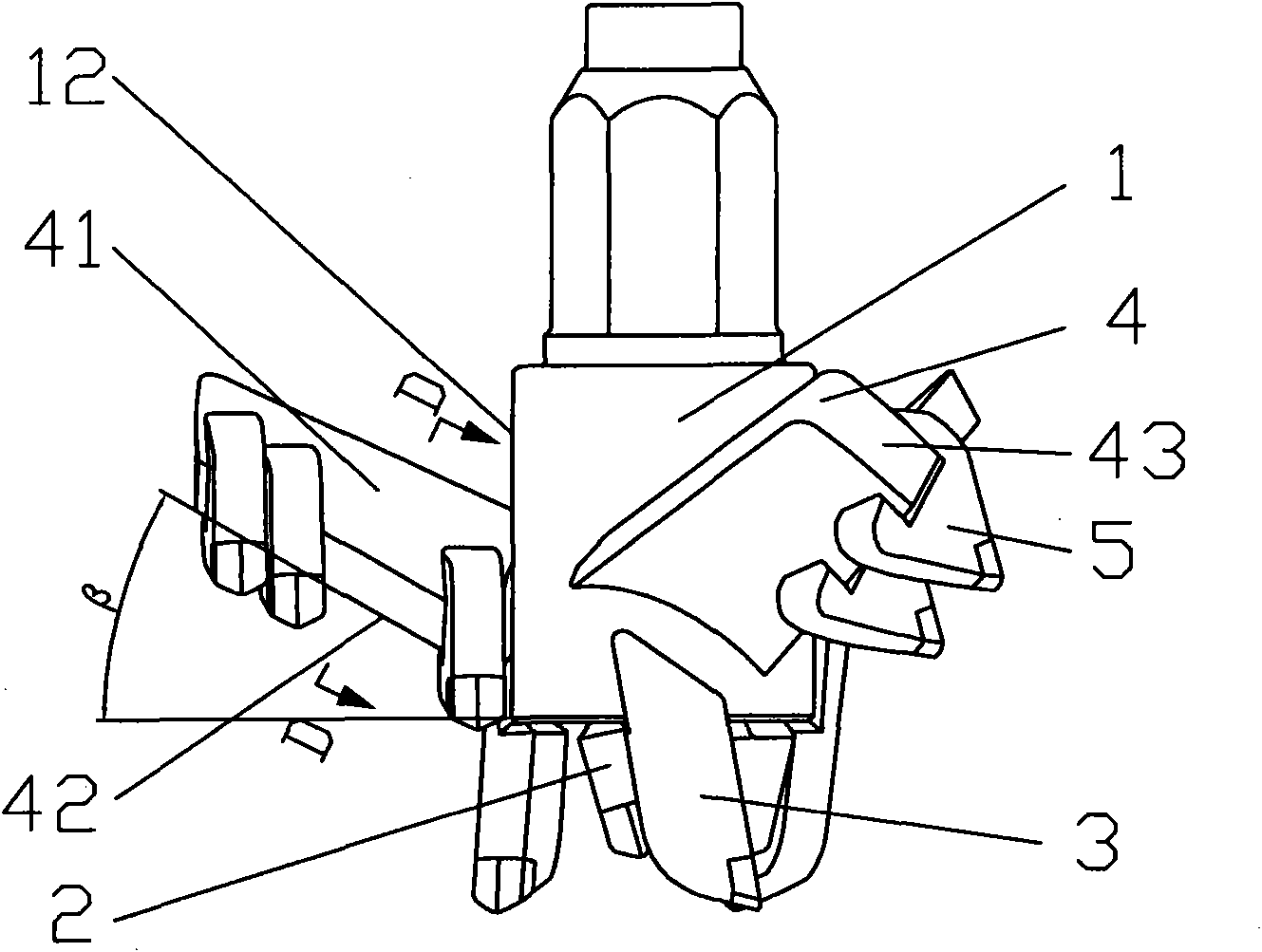

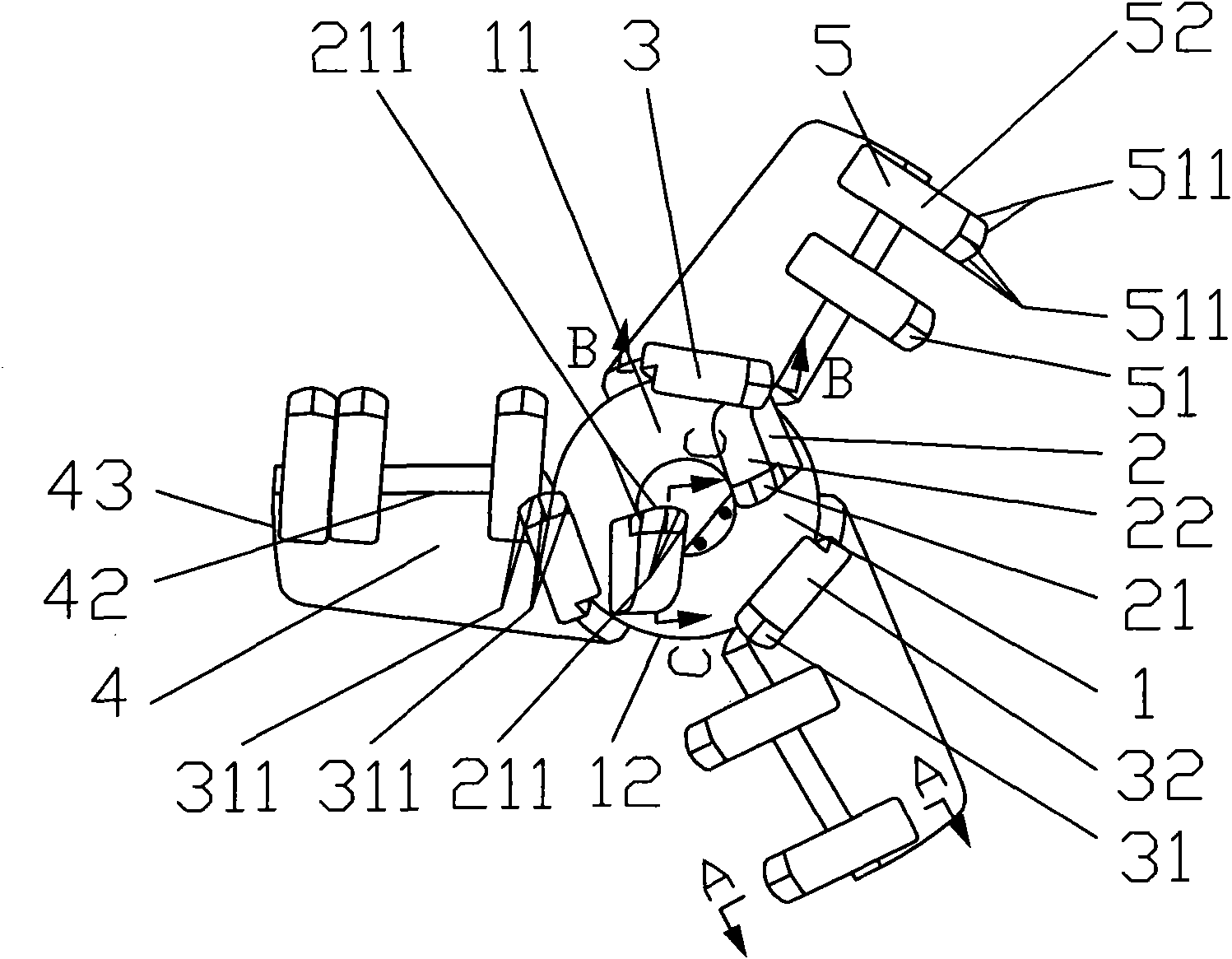

[0022] As shown in Figure 1, Figure 2, Figure 3, Figure 4, Figure 5 and Figure 6, a high-efficiency high-strength composite drill bit includes a drill pipe 1, a lower cutter body 2 composed of a lower cutter head 21 and a lower cutter handle 22, Inner cutter body 3, blade 4 made up of inner cutter head 31 and inner cutter handle 32, outer cutter body 5 made up of outer cutter head 51 and outer cutter handle 52; wherein, a through hole 11 is provided in the middle of the drill pipe 1 for cement Infusion of slurry; the lower cutter body 2 is fixed on the lower end of the drill pipe 1, there are 2 to 4 lower cutter bodies, the lower end of the rod body 1 is provided with a flange 13, and the installation direction of the lower cutter body 2 is to make the lower cutter head 21 is installed to face the direction of rotation of the drill pipe 1, and the lower handle 22 of the lower cutter body 2 is radially symmetrically welded and fixed on the lower end flange 13 of the drill pipe 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com