Bifurcate lap connection of reinforcing steel bars and connection method thereof

A technology of lap joint connection and connection method, which is applied in the processing of building materials, structural elements, building components, etc., can solve problems affecting the mechanical performance of steel bars, steel bar layout schemes, prefabricated concrete component production and construction complexity, etc., to achieve The effect of mechanical performance and reinforcement layout optimization, easy guarantee of construction quality and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

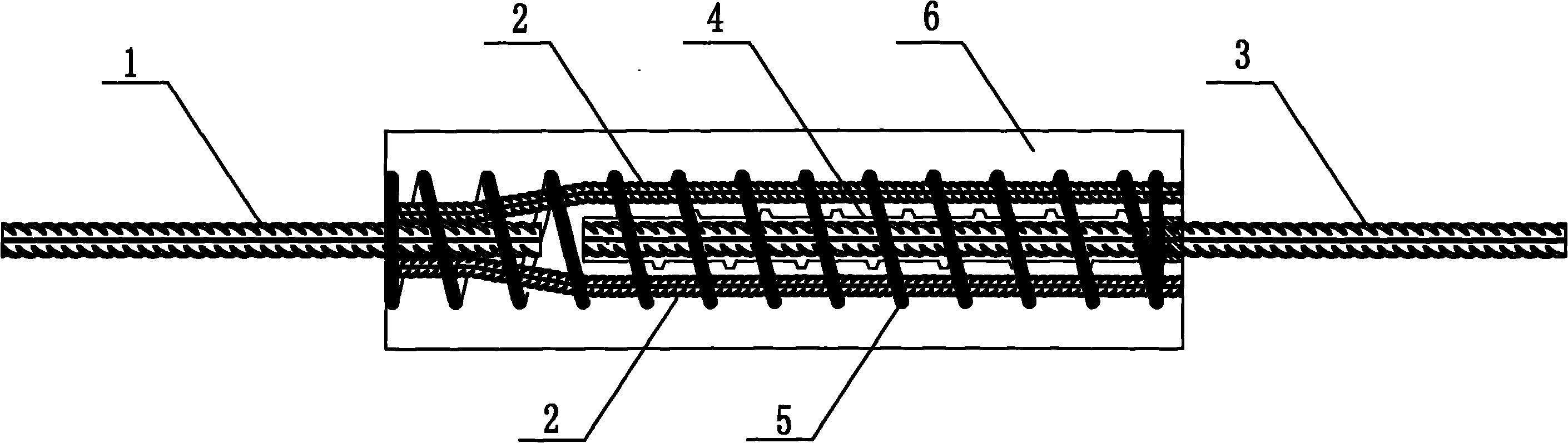

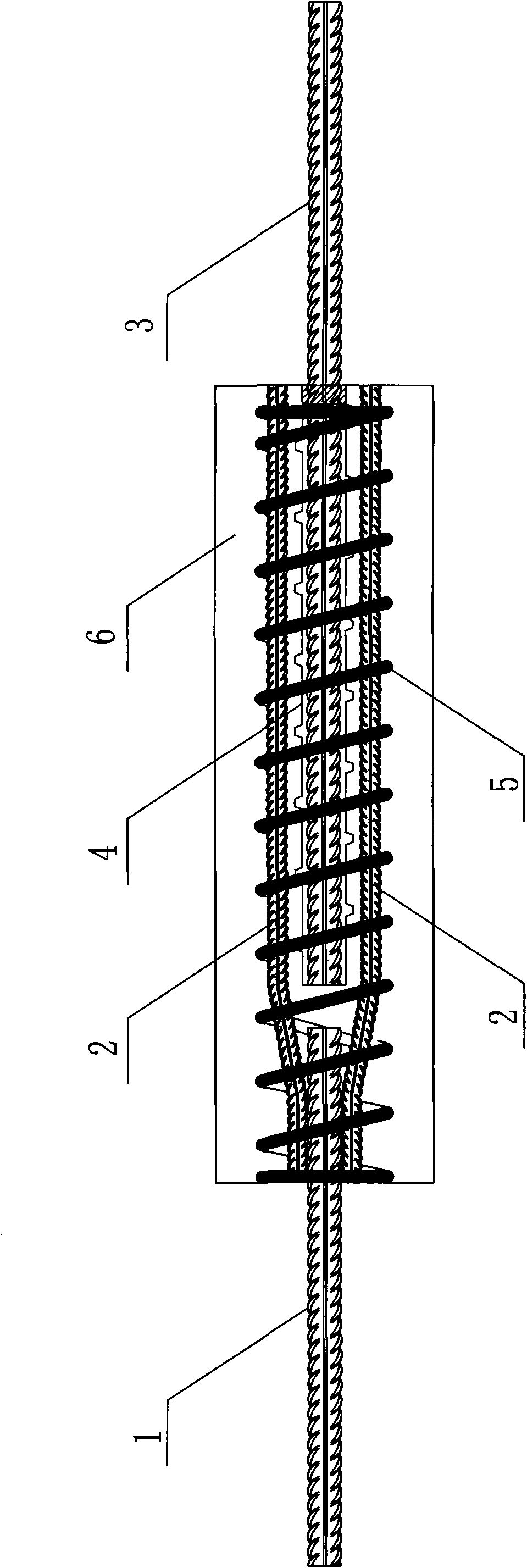

[0018] The steel bar bifurcated lap connection, its composition includes: the connected steel bar 1, the connected steel bar is connected with the bifurcated steel bar 2, and there is a reserved hole 4 concentric with the axis of the connected steel bar in the middle of the bifurcated steel bar. There is a connecting steel bar 3 in the reserved hole, a spiral reinforcing bar 5 is arranged on the outer circumference of the bifurcated steel bar in the axial direction, and concrete 6 is provided in the bifurcated steel bar section, as shown in the accompanying drawings.

[0019] For the bifurcated and overlapped connection of the reinforcing bars, the sum of the cross-sectional areas of the bifurcated reinforcing bars is equal to the area of the connected reinforcing bars or the connecting reinforcing bars.

[0020] The said reinforcing bar is bifurcated and overlapped, and said bifurcated reinforcing bar can be divided into two forks according to requirements, and each fork is ...

Embodiment 2

[0022] For the above-mentioned forked connection of steel bars, the said forked steel bars can be divided into three, four, five or six forks according to requirements, and each fork is evenly distributed around the connecting steel bars.

Embodiment 3

[0024] The connection method of the steel bar bifurcation lap connection includes the following steps:

[0025] a. Connect the bifurcated steel bar to the end of the connected steel bar by lap welding or special steel threaded connectors, and reserve a reserved hole concentric with the center of the connected steel bar in the middle of the bifurcated steel bar;

[0026] b. Insert connecting steel bars in the reserved holes, and arrange spiral reinforcing bars on the outer circumference of the bifurcated steel bars.

[0027] c. Pour concrete into the bifurcated steel bars.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com