Automatic yarn loading device for fully automatic hank mercerizing machine

A kind of mercerizing machine, fully automatic technology, applied in the direction of mercerizing of yarn/thread/filament, textile processing machine accessories, textile materials, etc., which can solve the problems of unfavorable workers' health, long machine standby time, inconvenient labor protection, etc. , to achieve the effect of automatic operation, reduced standby time, and easy speed regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

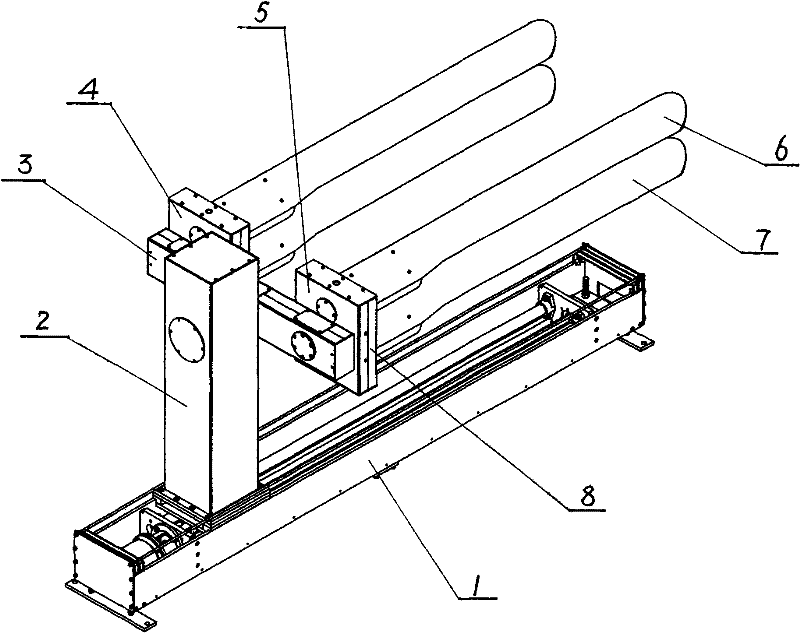

[0028] Such as figure 1 As shown, the automatic yarn loading device used for the automatic skein mercerizing machine includes a slide table 1, a column 2, a swing arm 3, and two sets of yarn hosting brackets 4 and 5, wherein,

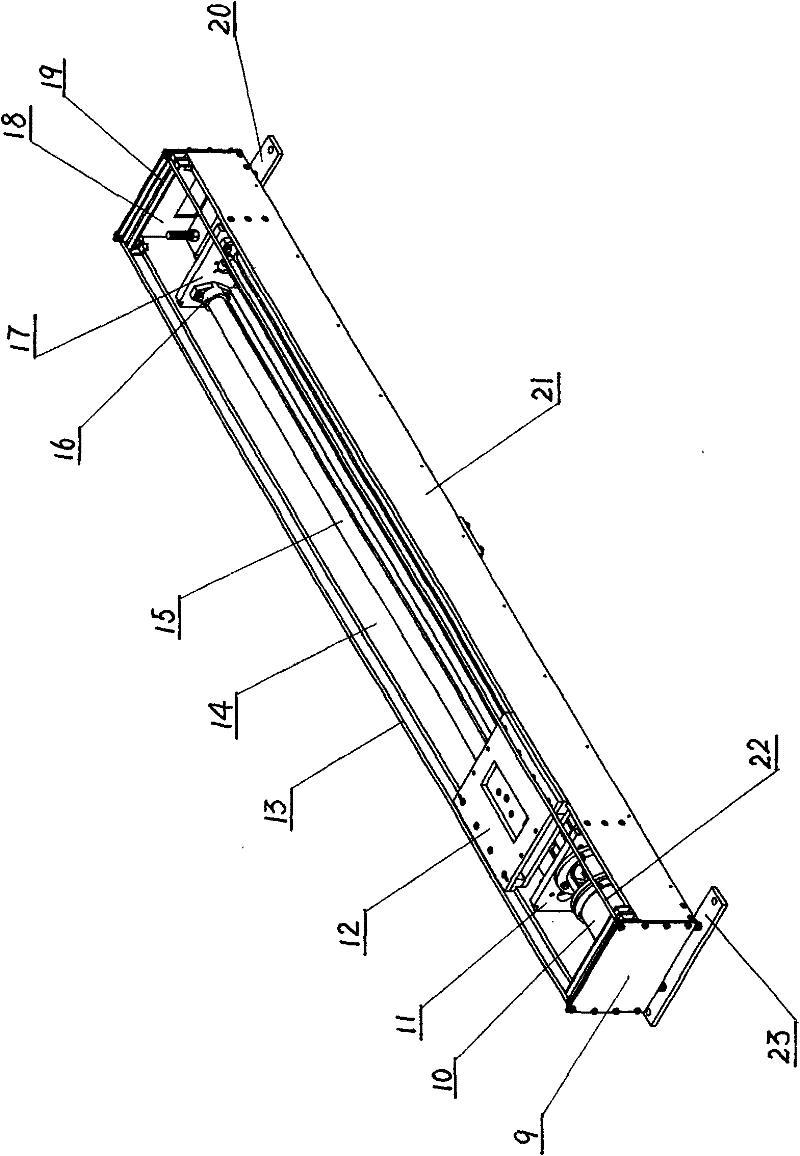

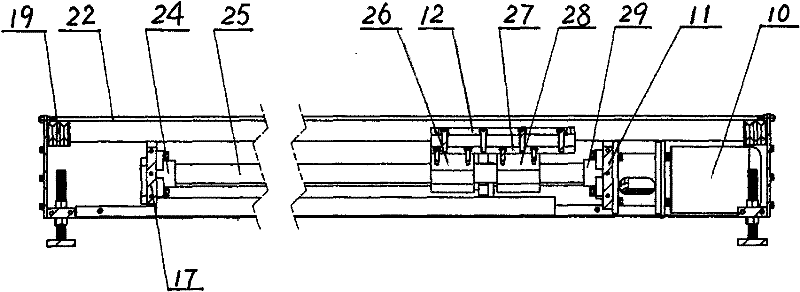

[0029] combine figure 2 , image 3 , Figure 4 As shown, the slide table 1 includes a slide table frame and a slide table seat 12. The slide table frame is a rectangular combined support, including two longitudinal support plates 14 and 21, two transverse support plates 11 and 17, and two end panels 9 and 18. In addition, there are two base plates 20 and 23, and the sliding platform seat 12 is assembled sequentially by a panel, a wear plate and a base plate, and two sets of linear bearings 31, 34 and 38, 39 are set on two optical axes 15 and 25, the optical axes 15 and 25 are installed on the transverse support pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com