Adjustable welding fixture device

A welding fixture and adjustable technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of poor interchangeability and sealing, difficult to correct, and low work efficiency, so as to improve the utilization rate of materials and reduce the loss of rework. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

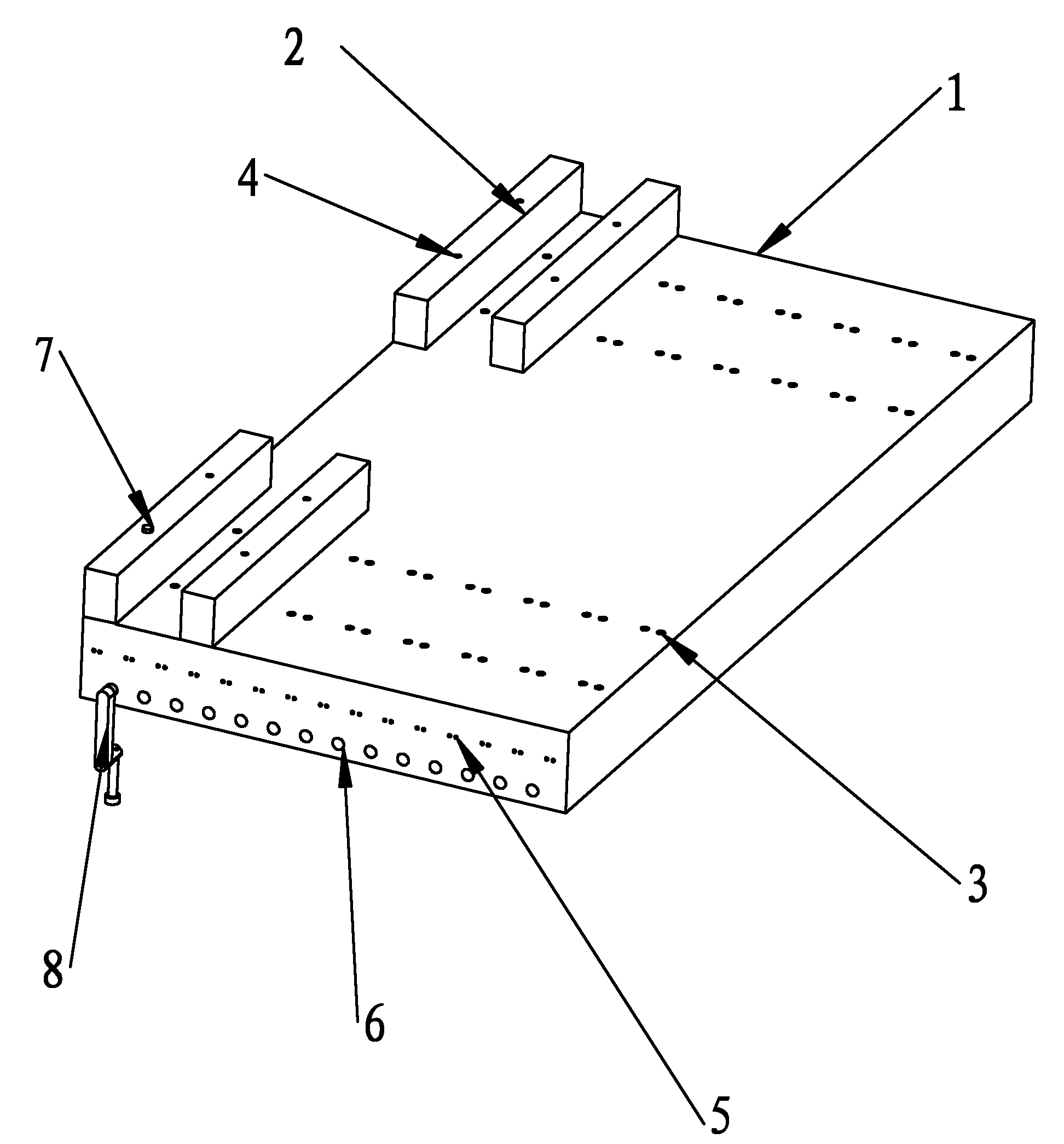

[0008] As shown in Figure 1: a number of platform positioning holes 3 are set on the upper surface of the working platform 1, and a number of side positioning holes 5 and pressing device holes 6 are set on the side, and the positioning block 2 is provided to match the platform positioning holes 3 on the working platform. The positioning block retaining hole 4 of the positioning block, and the pressing device 8 is installed in the holding device hole 6; during welding, based on the size of the weldment, adjust the position of the positioning block 2 on the working platform 1 to match the size of the weldment, It is fixed with the positioning hole 3 of the platform through the bolt 7, and the part of the weldment is fixed with the positioning hole 5 of the side through the bolt 7; the pressing device 8 is movable through the hole position 6 of the pressing device, and after the welding part is fixed on the working platform 1, turn over The compression device 8 compresses the weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com