Coaxial cable

A technology of coaxial cable and low density polyethylene, used in the manufacture of coaxial cable, coaxial cable/analog cable, insulated cable, etc., can solve the problems such as difficulty in maintaining the shape of the foam body and reducing the lateral pressure resistance of the insulating layer. , to achieve the effect of reducing the dielectric constant and reducing the delay time

Inactive Publication Date: 2010-08-18

POLYPLASTICS CO LTD

View PDF4 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, foaming may reduce the lateral pressure resistance of the insulating layer, which may cause difficulty in maintaining the shape of the foam

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

Embodiment 8

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Login to View More

Abstract

This invention provides a high-frequency coaxial cable comprising an inner conductor and an insulator layer covering the surface of the inner conductor. In the coaxial cable, the insulator layer has satisfactory side pressure resistance, and the attenuation level in the transmission is low. An insulating layer having a higher foaming level and a higher mechanical strength as compared with the conventional insulating layer can be formed by foam molding a resin composition comprising a cyclic olefin resin, a high-density polyethylene, and a low-density polyethylene and / or a linear low-density polyethylene. As a result, the insulator layer covered on the inner conductor in the coaxial cable has lowered dielectric loss tangent and lowered permittivity and possesses excellent transmission characteristics and mechanical properties.

Description

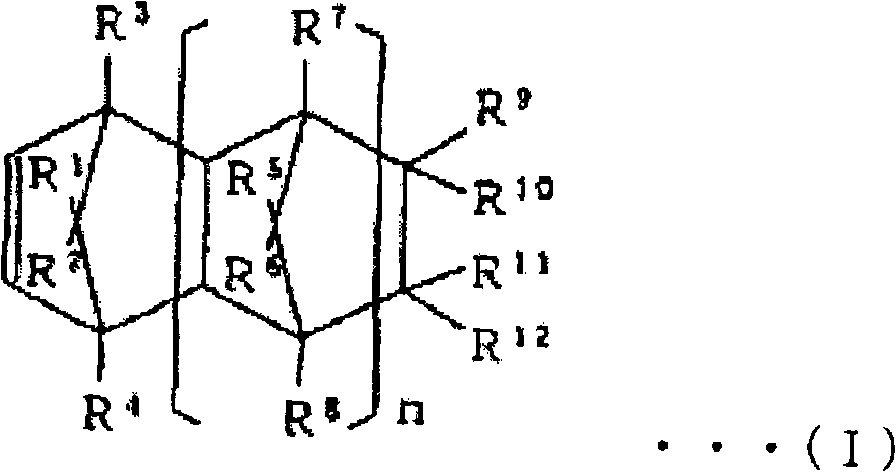

technical field The present invention relates to a coaxial cable using a cyclic olefin resin. Background technique In recent years, there has been an increasing demand for broadband communication such as mobile phones, the Internet, and wireless LANs (Local Area Networks). In addition, in order to transmit information at a higher speed and in large quantities, the frequency increase of electric signals is progressing remarkably. Therefore, there is a demand for a coaxial cable with a small amount of attenuation and a small signal delay in a high frequency band. A coaxial cable is mainly composed of a central conductor, an insulator layer provided thereon, and an outer conductor provided on its outer periphery. Low attenuation in high-frequency bands is important, and it is most effective to reduce the dielectric loss tangent of the insulating layer for realizing high-frequency coaxial cables. In addition, foaming is effective for further reducing attenuation. However, f...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01B7/02H01B3/44H01B11/18

CPCH01B13/016H01B3/441H01B11/1839

Inventor 谷北真澄芹泽肇

Owner POLYPLASTICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com