Multicomponent cartridge for one-time use

A multi-component, cartridge technology, which is applied to the device for coating liquid on the surface, medical science, dentistry, etc., can solve the problems of less sealing problems, the inability to achieve stable quality of filling materials, etc., and achieve the effect of improved reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

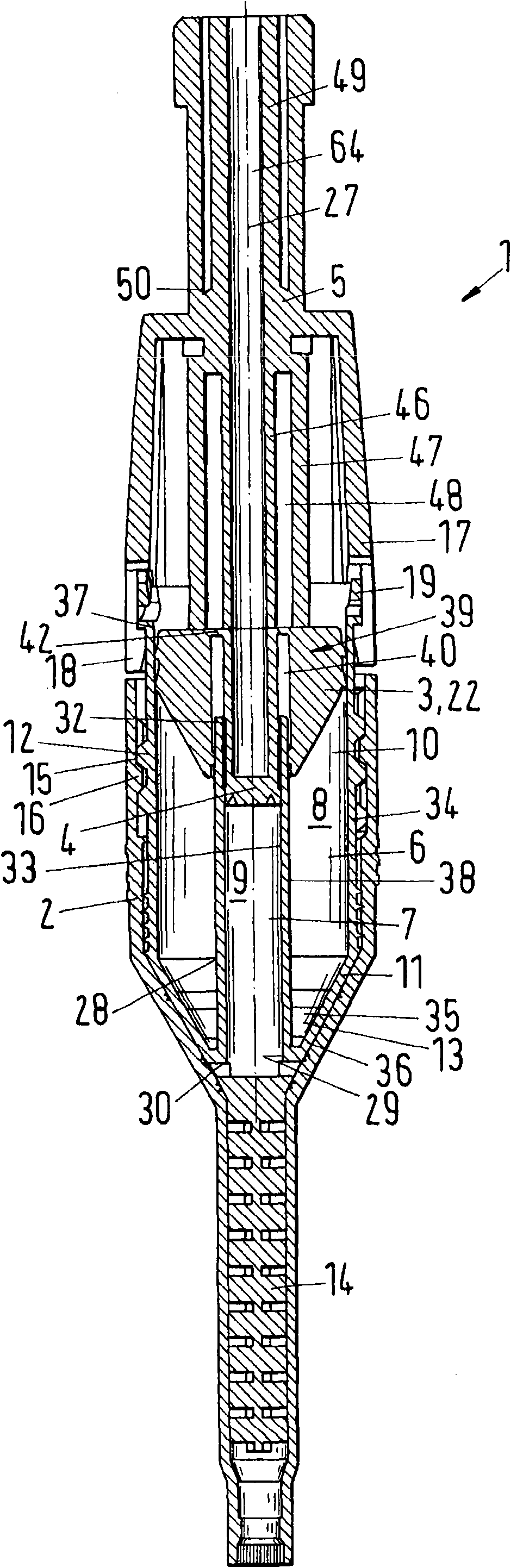

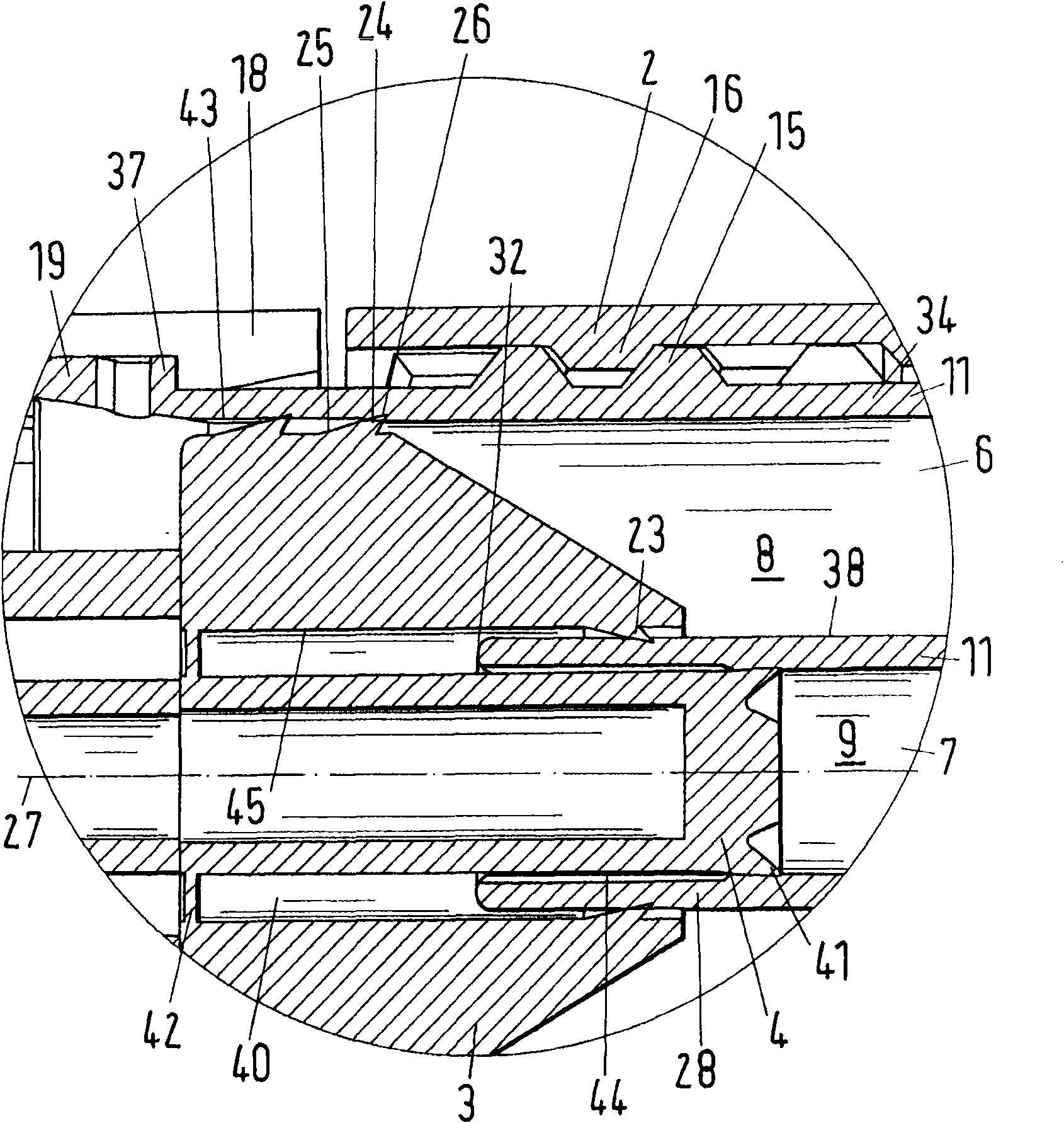

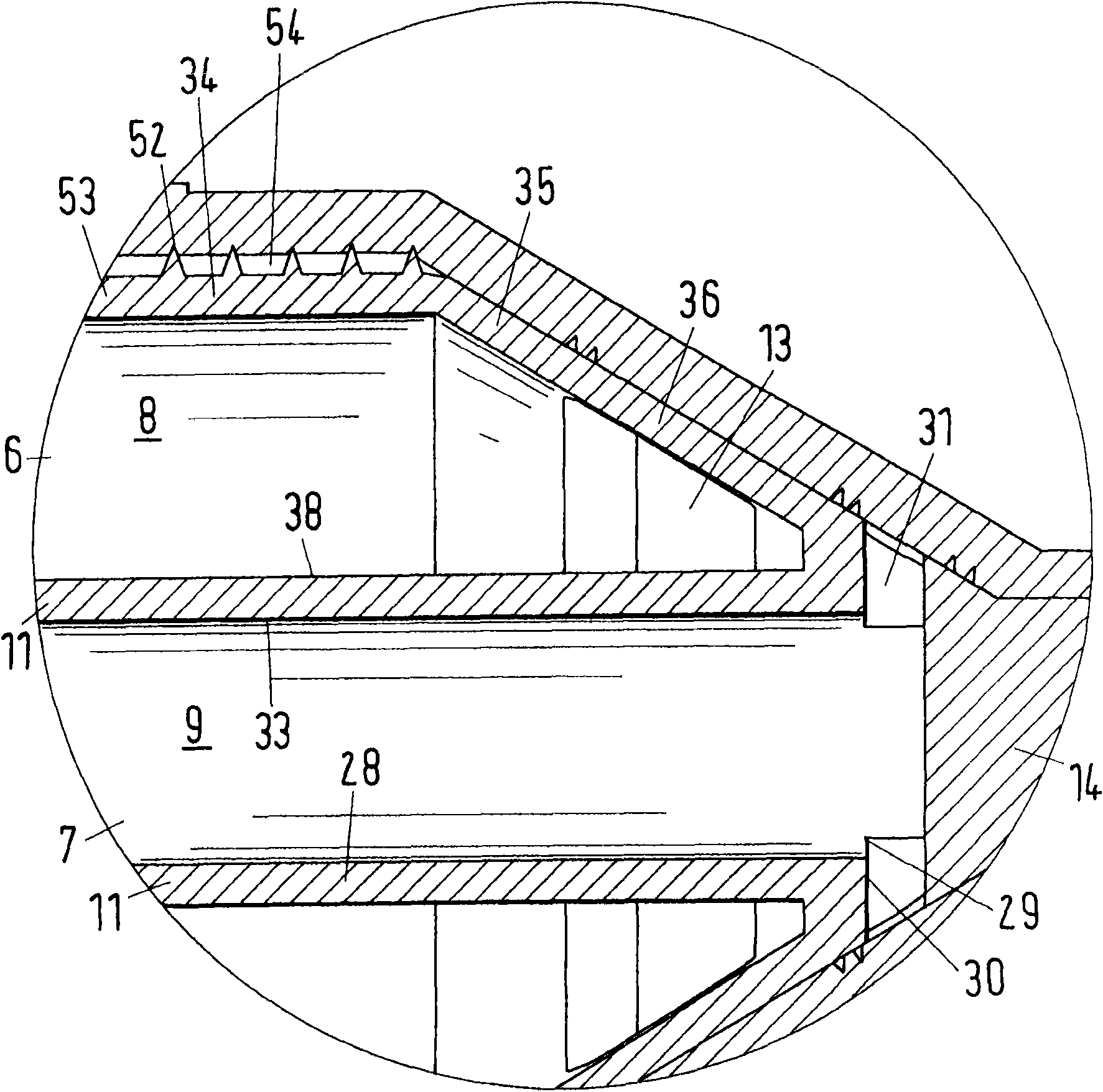

[0046] figure 1 A first embodiment of a multi-component cartridge designed for single use according to the invention is shown. In particular, such multi-component cartridges are used to dispense small and very small quantities of fill material. The multicomponent cartridge 1 comprises a first supply chamber 6 for a first component 8 and a second supply chamber 7 for a second component 9 . The first supply chamber 6 is isolated from the second supply chamber 7 so that the two components do not come into contact with each other. These components generally react with each other as soon as they come into contact with each other, wherein a chemical reaction can take place. Interaction of components is often a desired effect in an application, but is unnecessary as long as the components have not been used in their defined application. Therefore, before the multi-component cartridge can be used, it is actually sometimes necessary to store and transport the multi-component cartrid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com