Temperature Controlled Circulation Pickling System and Its Application

A circulatory system and product technology, applied in application, food preparation, confectionery, etc., can solve the problems of uneven liquid seasoning concentration, inability to adjust liquid seasoning, long pickling cycle, etc. The effect of controlling the marinating environment and improving the marinating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

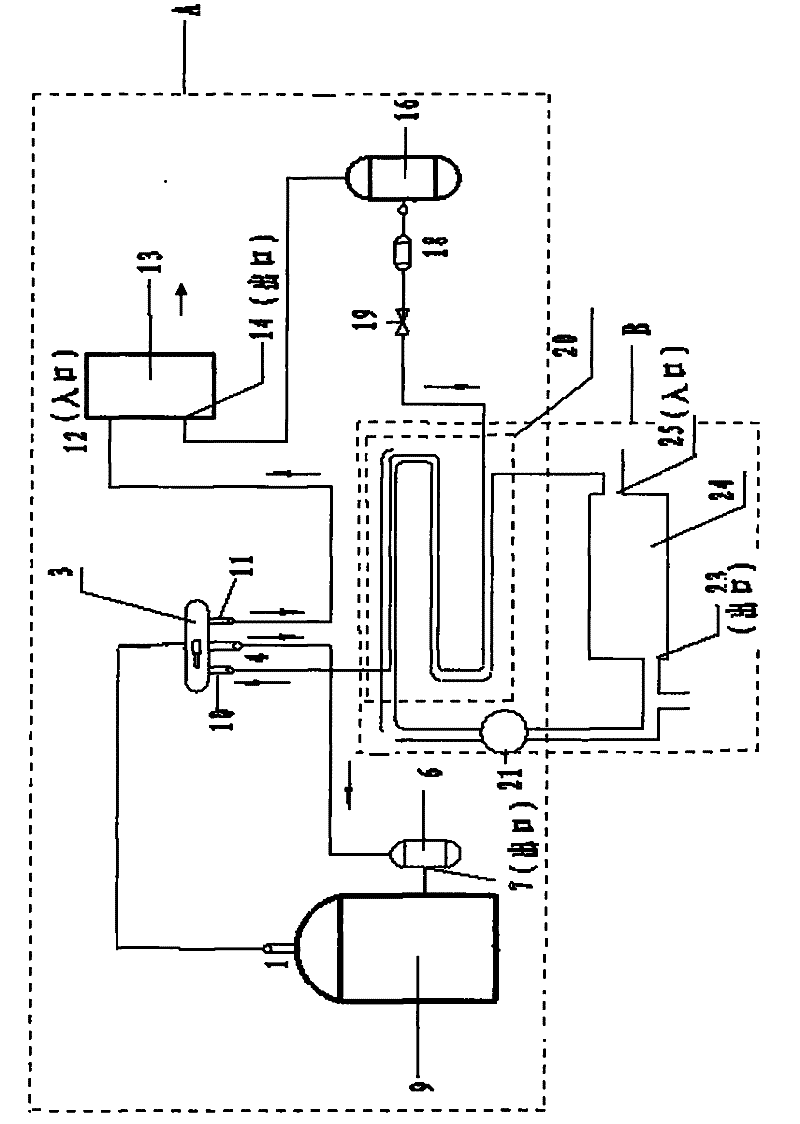

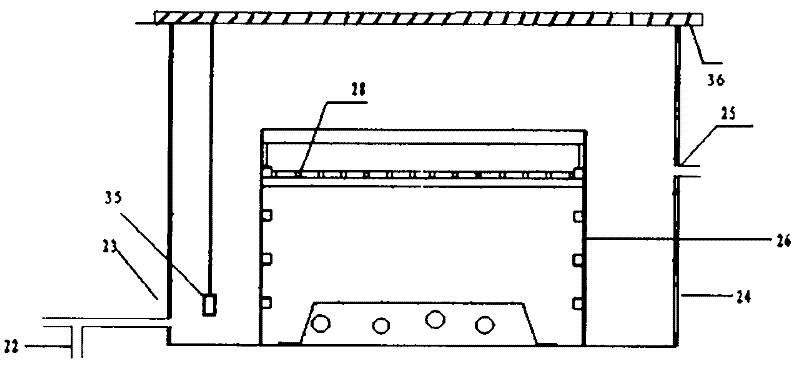

[0028] The following comparison is attached Figure 1-9 The system of the present invention and its application are described in detail.

[0029] This embodiment is described by taking the implementation of a refrigeration cycle system as an example. figure 1 The refrigerant circuit of the refrigeration cycle device shown includes a compressor (9) for compressing refrigerant (Freon R22), a four-way reversing valve (3) for changing the direction of refrigerant flow, and a condenser for condensing high-pressure and high-temperature refrigerant ( 13), a two-way filter (18) for filtering the condensed refrigerant, a throttling device (19) for decompressing the condensed refrigerant, and an evaporator (20) for evaporating the decompressed refrigerant A refrigeration cycle system composed of pipes connected in sequence. The pickle solution fluid circuit B includes a pump (21) for transporting the pickle solution, an evaporator (20) and a sample pool (24) for temperature-controlli...

Embodiment 2

[0036] Get 8.5L of hot water at 75°C and add 170g of tea leaves. After filtering, take 1.5kg of table salt and dissolve it in the tea, and add 25.5g of malic acid (or lactic acid or citric acid) to prepare a pickling solution.

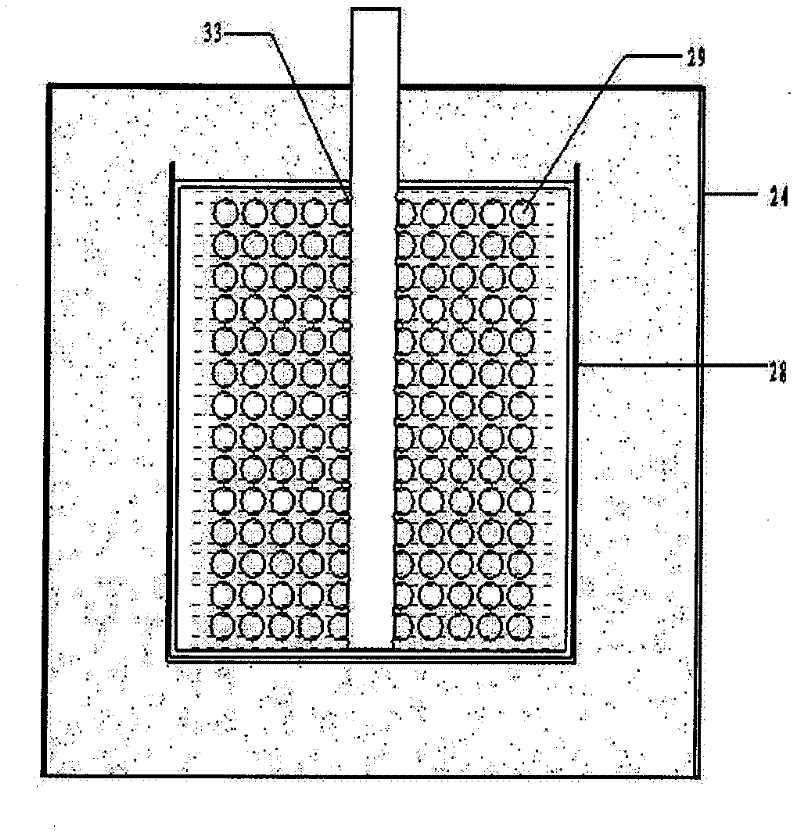

[0037] Add 30-60 egg yolks to the pickling solution, the egg yolks used must be fresh and uniform in size, and after separating the egg whites, put the egg yolks in egg yolk molds, see Figure 6 .

[0038] The samples were marinated at 25°C, and the temperature control accuracy of the setting was ±1°C. If the temperature of the pickling solution is 15°C, set the temperature to 24°C with a temperature difference of 2°C, and the temperature control mode is heating mode (JHH). When the temperature of the pickling solution is 15°C, the temperature is required to be 5°C during pickling, and the temperature control accuracy is ±1°C, then the temperature is set to 4°C, the temperature difference is 2°C, and the temperature control mode is refrigeration mode ...

Embodiment 3

[0041] Raw materials: cucumber 10kg, salt 0.3kg, brown sugar or white sugar 3kg, vinegar 5kg.

[0042] Wash and slice the cucumbers, sprinkle a layer of edible salt on top, pre-marinate for 3-4 hours, take out the cucumbers, and drain the water.

[0043] Boil sugar and vinegar in a pot, mix well, let cool to make sweet and sour liquid. Put the desalted cucumber strips together with the prepared sweet and sour liquid into the tank for sweet and sour pickling. The sweet and sour pickled products are kept at 25°C in the sweet and sour pickled pool, and the flow rate of the circulating pump is set at 16L / min. Porous distribution The size of the length × width of the groove is 35×25cm, and the groove hole is a uniform circular hole with a diameter of 0.6cm, a total of 108. The height of the porous distribution channel and the upper surface of the egg yolk mold is 3cm, and it is turned once a day, and the finished product can be finished in 2-3 days. The texture of the product is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com