Turntable type potato harvesting machine

A potato and harvester technology, applied to digging harvesters, harvesters, excavators, etc., can solve the problems of high use cost, heavy machine body, large amount of clay, etc., to prolong the service life of machinery, quickly and fully separate, and not easy clay effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

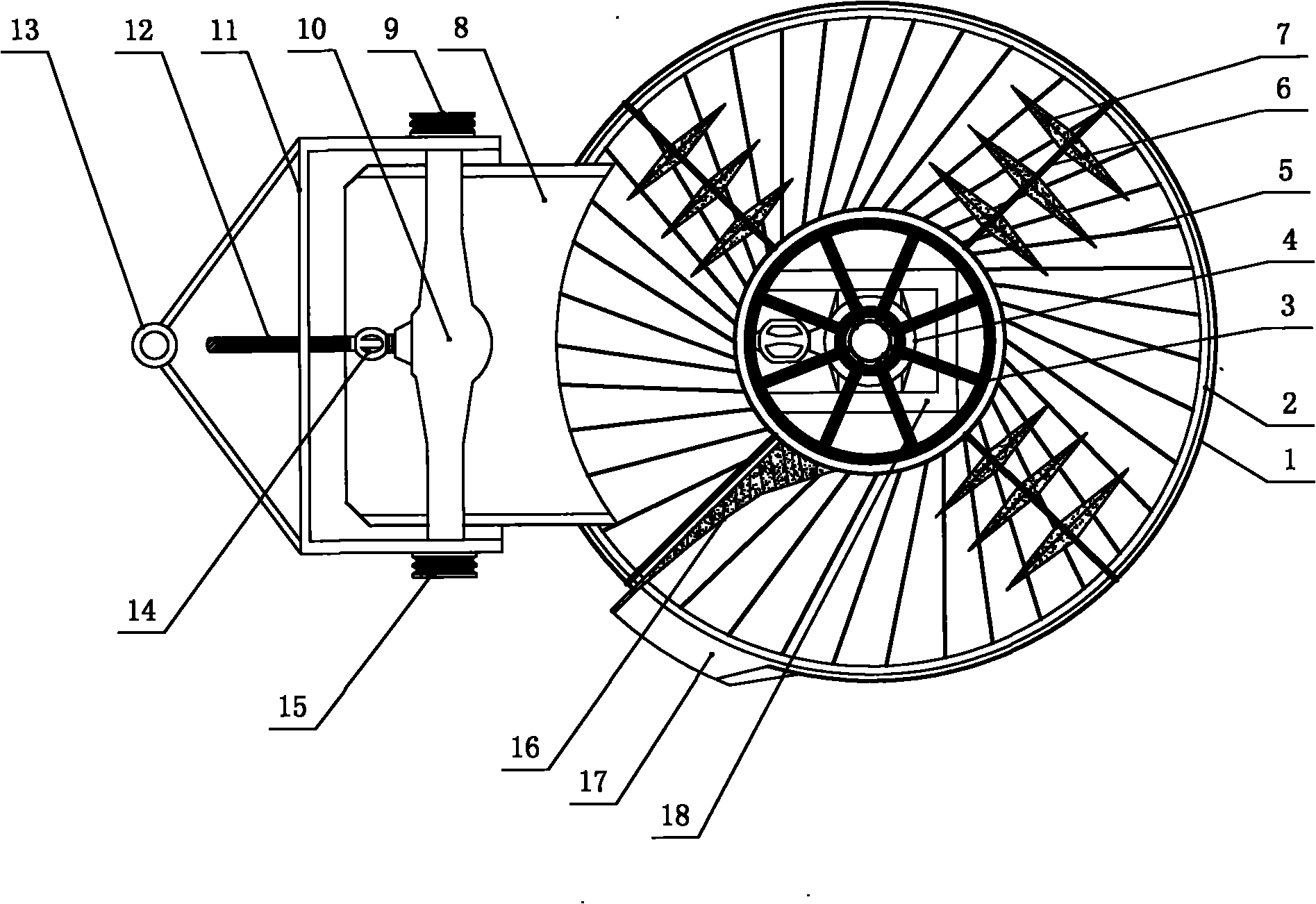

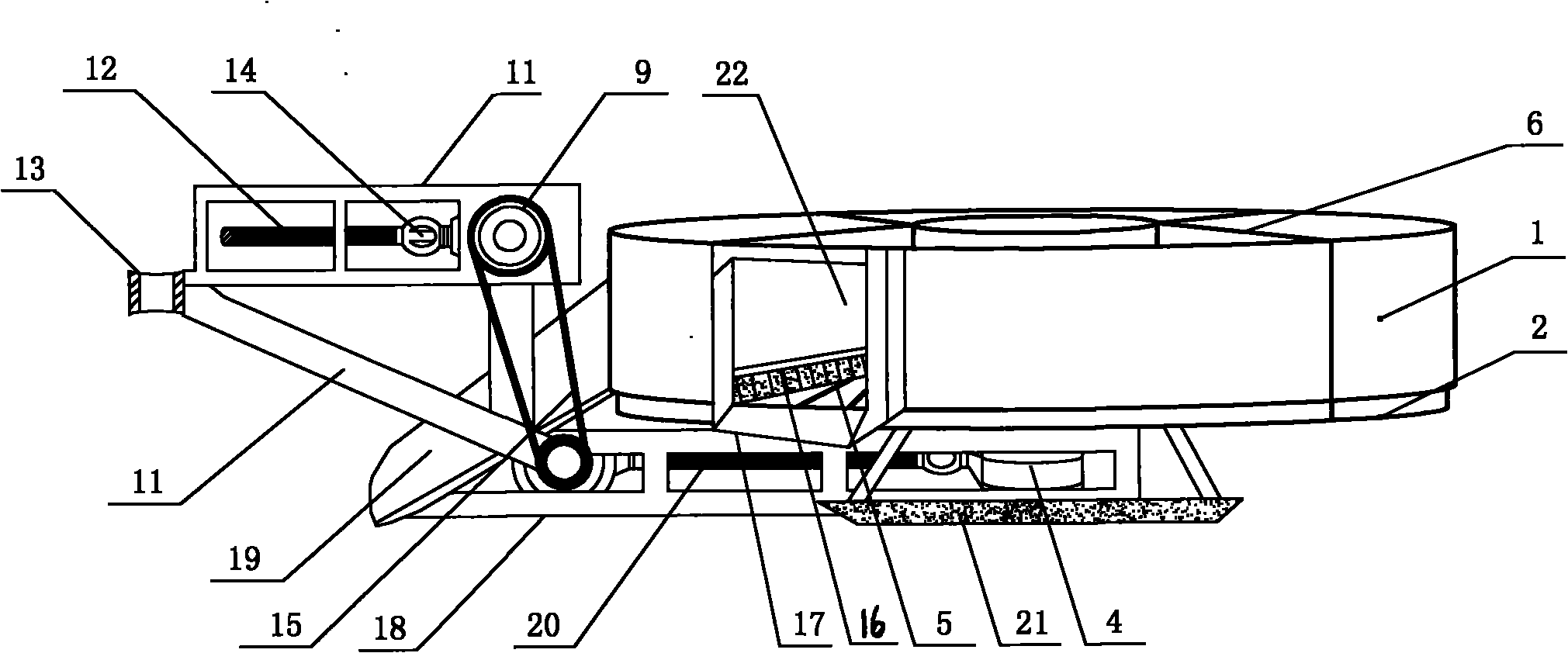

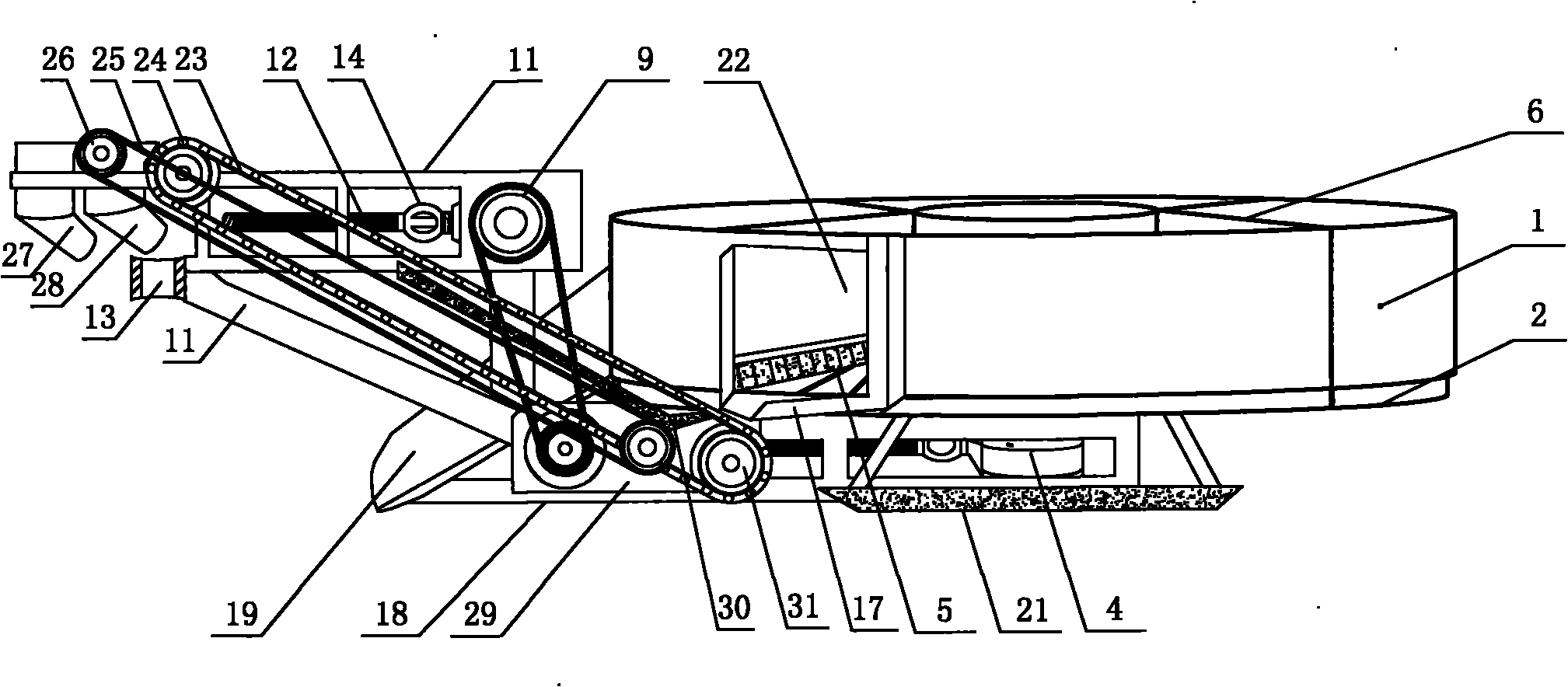

[0014] figure 1 figure 2 The implementation mode in the accompanying drawings is: including the traction mechanism and the connecting turntable separation mechanism, and selecting the automatic screening separation mechanism. The working method of the present invention is to excavate by connecting the tractor to the traction mechanism, and separating the soil and potatoes through the turntable separation mechanism, or Select Auto Filter Separation.

[0015] According to the traction mechanism, it is characterized in that: the upper end of the mechanism support (11) is provided with a mechanism tooth box (10), and the two ends of the mechanism tooth box (10) are pulleys (9) and transmission belts (15), which are connected to the gear box by transmission. The mechanism support (11) lower end is a digging shovel (8), and the mechanism support (11) front end is a traction hole (13), and the traction hole (13) is connected on the tractor.

[0016] The mechanism tooth box (10) is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com