Power supply method and system of LED display screen

A technology of LED display screen and power supply method, which is applied in the direction of control/regulation system, electrical components, and adjustment of electrical variables, etc. It can solve the problems of increased wiring difficulty, low reliability, increased equipment cost and maintenance cost, etc., and achieves convenient operation and management and maintenance, high power conversion efficiency, and improved power supply efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

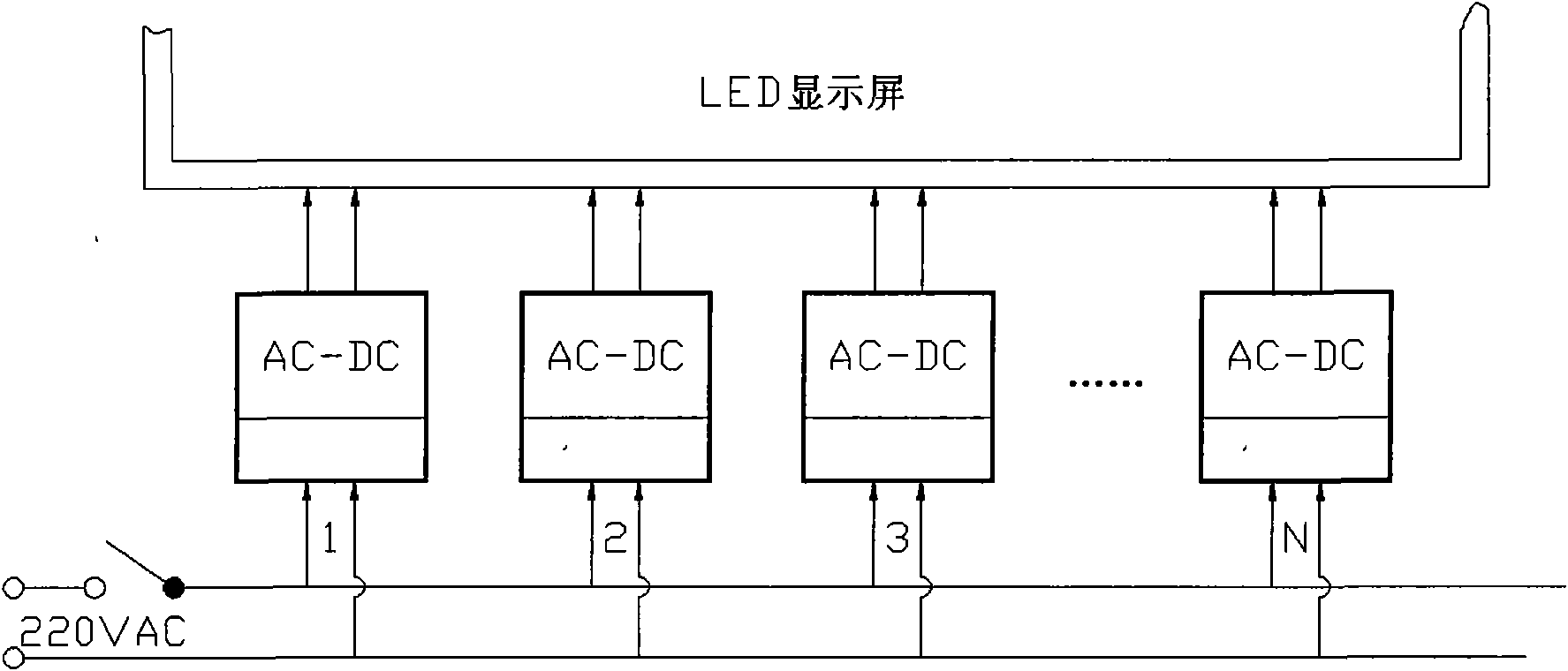

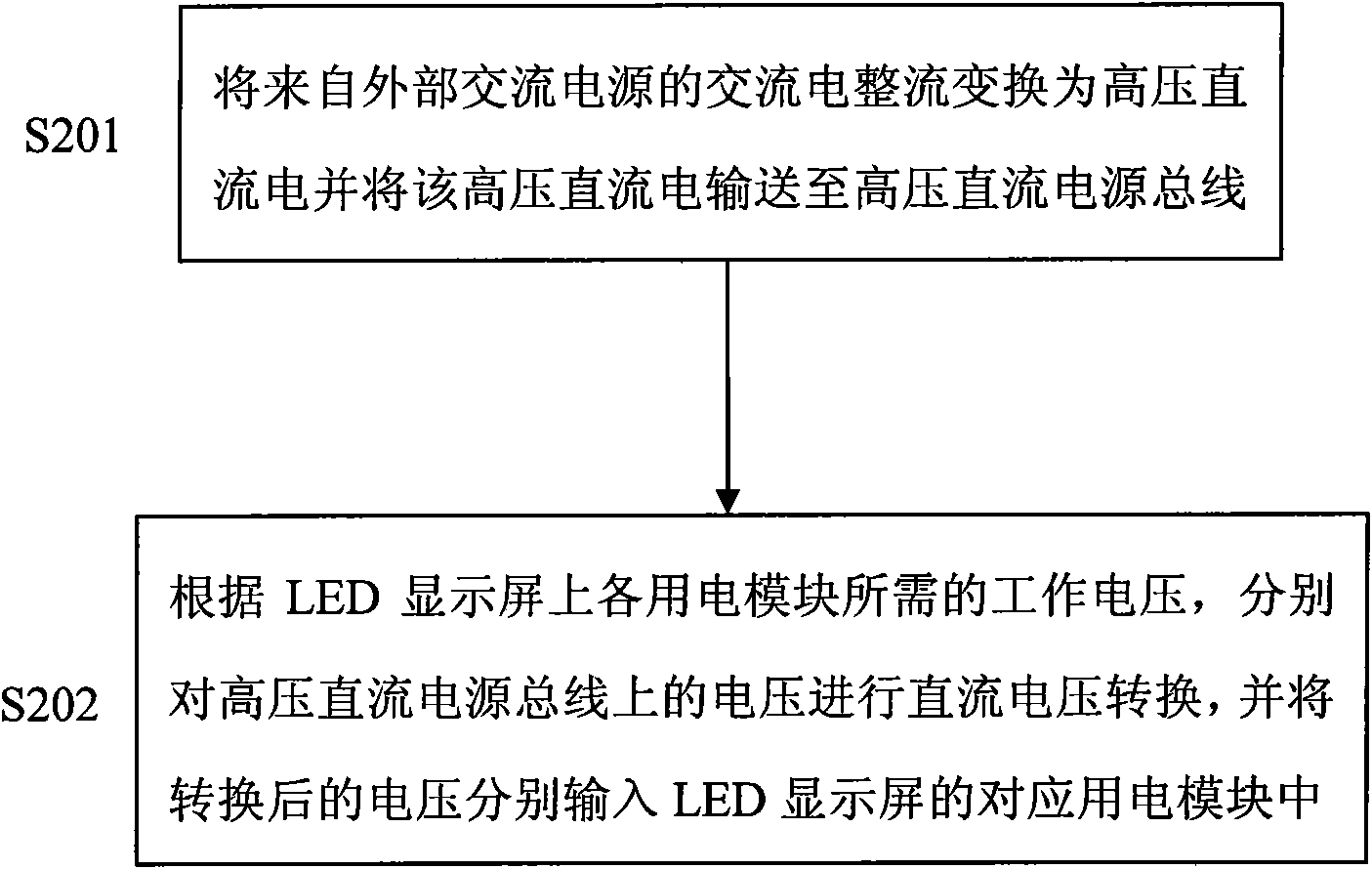

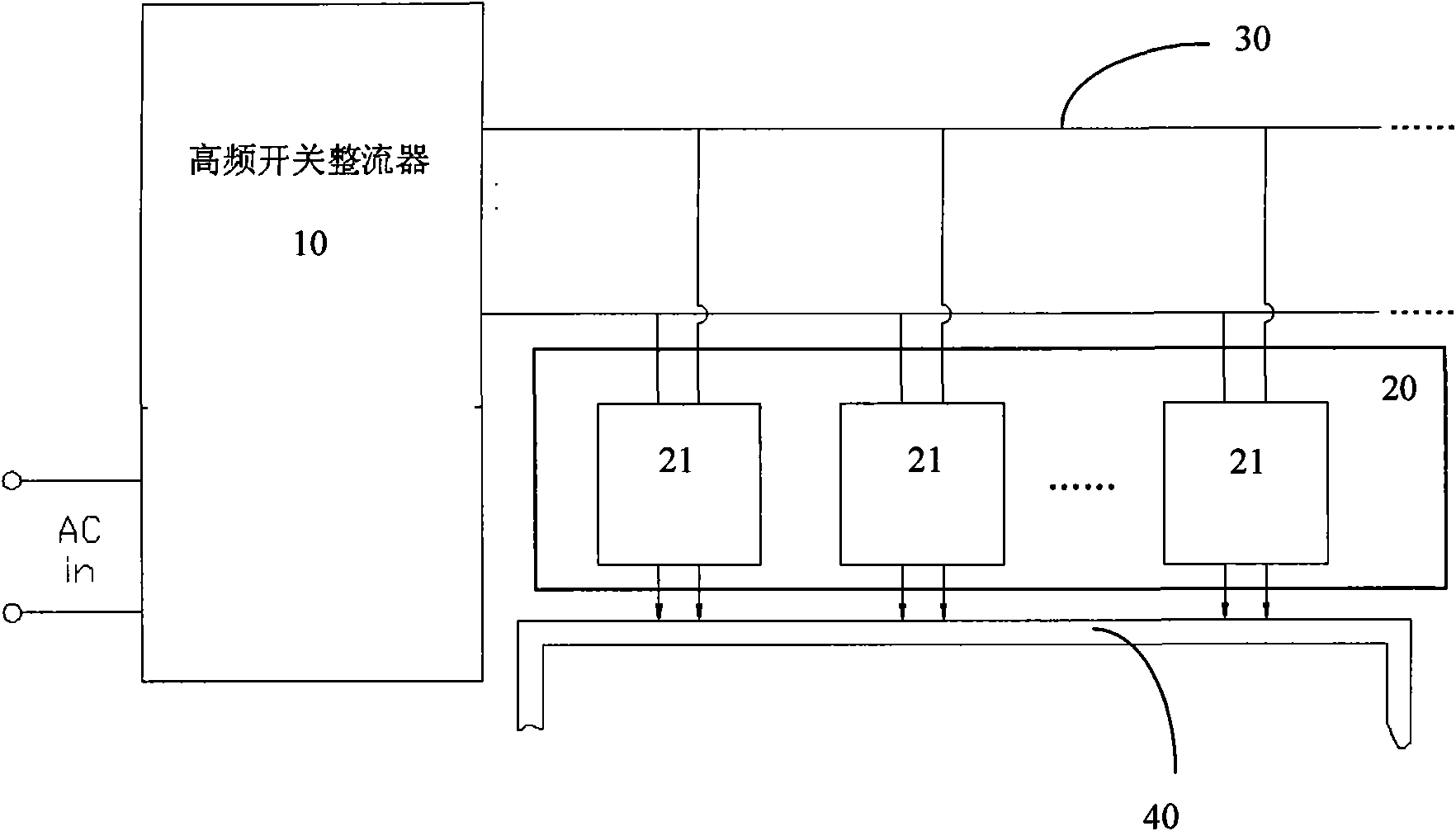

[0034] Such as figure 2 As shown, the power supply method of the LED display screen of the present invention is: firstly, the AC power from the external AC power supply (single-phase or three-phase) is subjected to AC-DC rectification conversion, converted into high-voltage direct current, and the high-voltage direct current is delivered to the high-voltage direct current power supply bus On, step S201. This conversion process can be realized by using a high frequency switching rectifier.

[0035] A high-frequency switching rectifier is an AC / DC (AC / DC) power electronic device that uses the principle and technology of electronic switches to rectify single-phase or three-phase alternating current into smooth direct current. In the power supply method of the present invention, the high-frequency switching rectifier is used to realize the AC-DC rectification conversion of the single-phase or three-phase AC from the outside, and output tens or hundreds of volts of high-voltage D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com