Silane-modified white carbon black-carbon black composite filling and preparation method thereof

A technology of silane modification and composite filler, which is applied in the direction of fibrous filler and dyed organosilicon compound treatment, which can solve the problems of delayed vulcanization, high surface area, and increased processing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

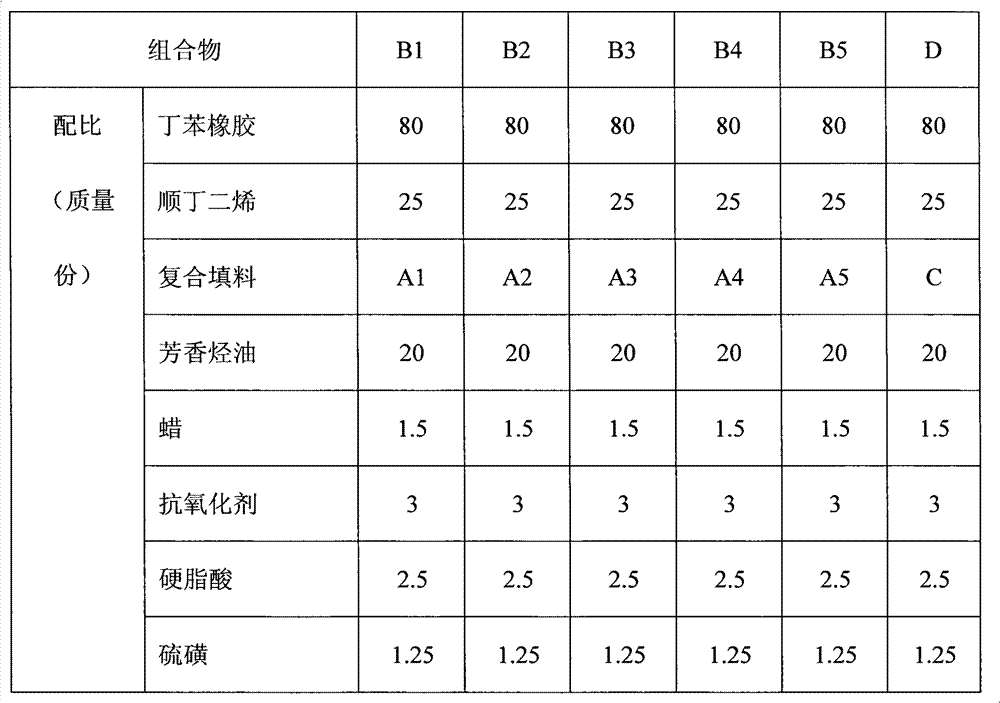

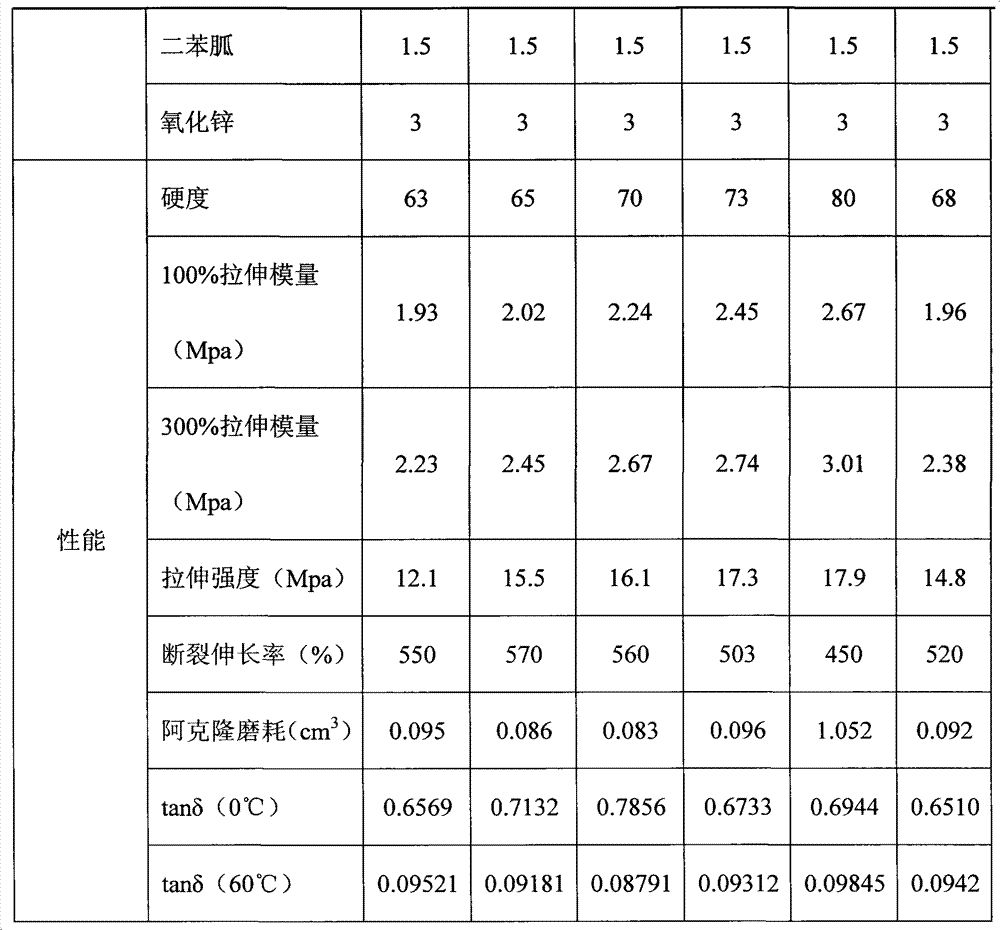

Embodiment 1

[0023]The precipitated silica and the fumed silica were added into the high-speed mixer according to the ratio of 60:20 parts by mass (3:1), and stirred for 5 minutes. Pre-hydrolyzed 6 parts by mass of polysulfide silane (bis-[3-(triethoxysilyl)propyl]-tetrafluorosilane) in a solution of water and isopropanol (isopropanol:water=95:5V / V) Sulfide (TESPT), 6 mass parts of polysulfide silane pre-hydrolyzed in 20 mass parts of water and isopropanol solution) slowly and uniformly added in the form of spray (using nitrogen as carrier gas to atomize the polysulfide pre-dissolved in the solvent) Sulfur silane), continue to feed nitrogen for protection, gradually raise the temperature to 100-120°C and keep it for 60 minutes to promote the surface modification reaction to be complete. In the case of continuing to stir and keep warm, add carbon black according to the ratio of carbon black to white carbon black (gas-phase white carbon black and precipitated white carbon black) 1:10-1:5 and...

Embodiment 2

[0031] The preparation method is basically the same as in Example 1, wherein the filler proportion is A2 in Table 1, and the polysulfide silane is two-[3-(triethoxysilyl)propyl]-disulfide dissolved in ethanol (TESPD). Composite filler A2 was obtained.

[0032] Then prepare composition B2 and its samples according to Table 2 to measure physical or mechanical properties.

Embodiment 3

[0034] The preparation method is basically the same as in Example 1, wherein the filler ratio is A3 in Table 1, and the polysulfide silane is 3-octanoylthio-1-propyltriethoxysilane dissolved in ethanol. Composite filler A3 was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com