Frequency conversion power saving control method of ball mill

A technology of energy-saving control and ball mill, which is applied in the direction of grain processing, etc., and can solve the problems of large difference in fineness between different batches, unfavorable energy saving, excessive grinding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

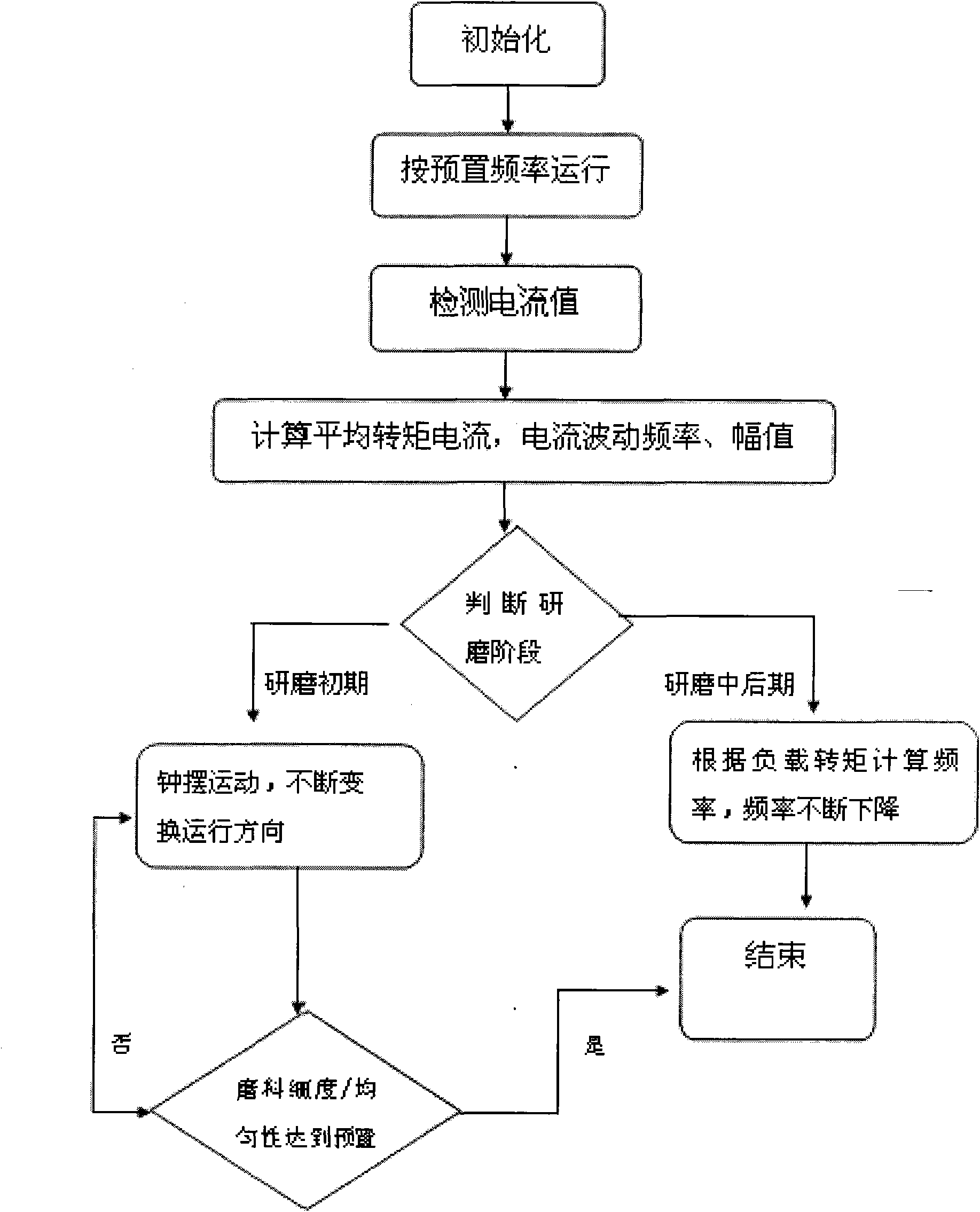

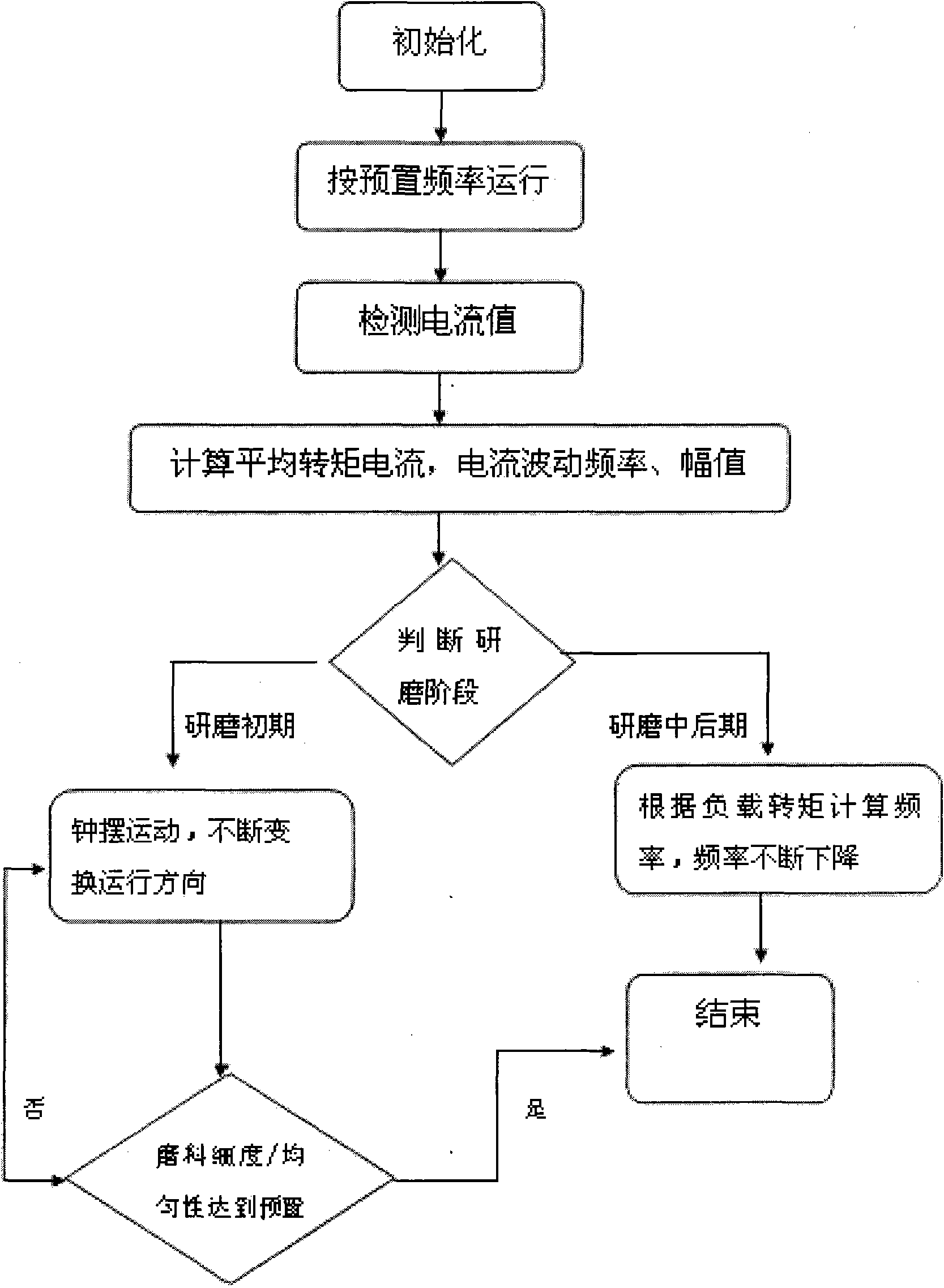

[0013] Please refer to figure 1 , the present invention will be further described below in conjunction with the following embodiments:

[0014] A frequency conversion power-saving control method for a ball mill, which is mainly realized by the following methods:

[0015] Step 1: Turn on the ball mill and initialize the preset controller inside the ball mill.

[0016] Step 2: The ball mill operates according to the preset frequency.

[0017] Step 3: Detect the instantaneous value of the stator current of the stator current of the AC asynchronous motor of the ball mill, which measures the instantaneous value of the stator current through the U\V\W three-phase current Hall sensor inside the frequency converter preset in the ball mill.

[0018] Step 4: Calculate the average torque current, current fluctuation frequency, and amplitude of the stator current of the AC asynchronous motor of the ball mill, and obtain the current torque component and current fluctuation amplitude by v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com