Fuel delivery unit with a filling level sensor operating with ultrasonic waves

一种输送单元、超声波的技术,应用在液面指示器、液体燃料给料机、仪器等方向,能够解决测量管不能最佳等问题,达到成本低廉的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

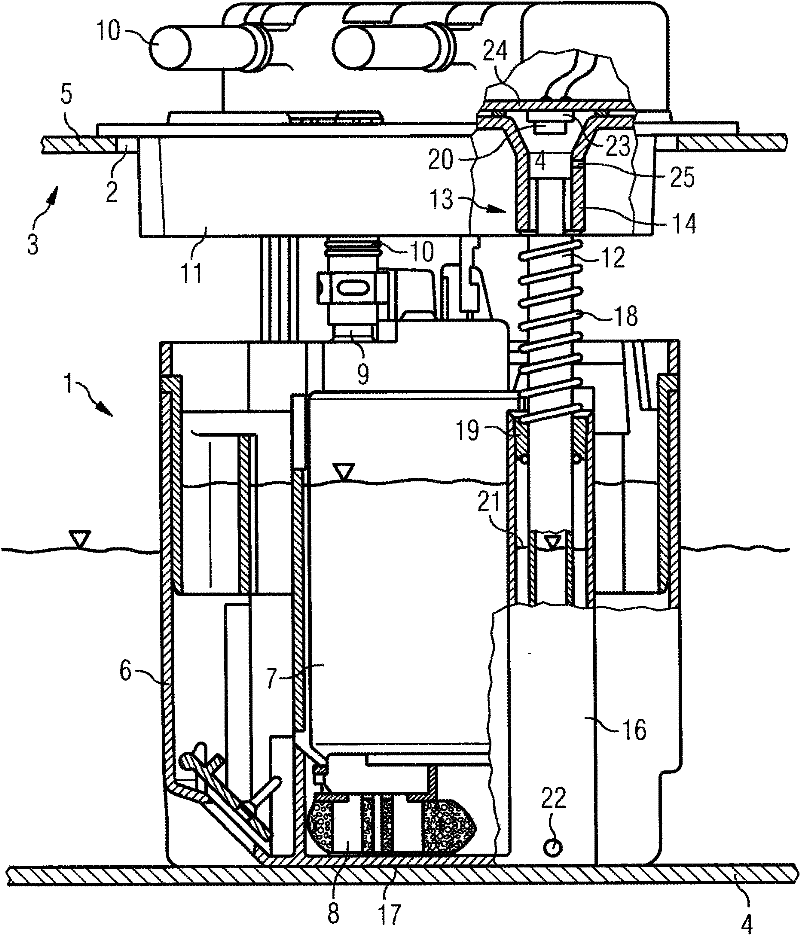

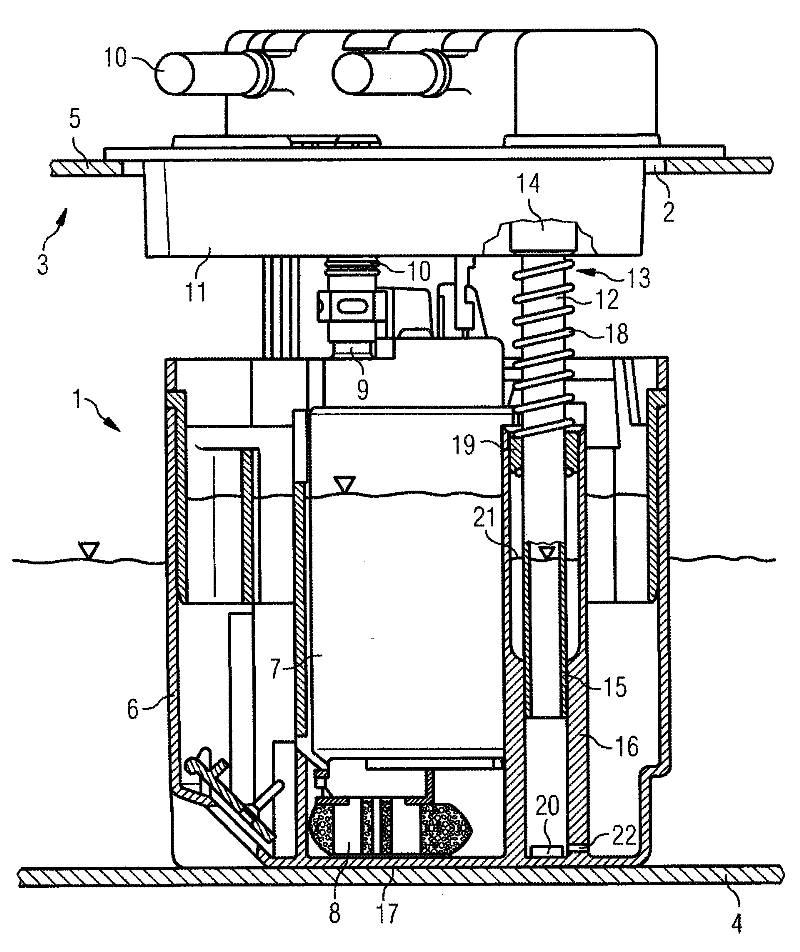

[0019] figure 1 The fuel delivery unit 1 in is inserted into the fuel tank 3 through the opening 2. The fuel tank 3 has a bottom 4 and an upper boundary wall 5 . The fuel delivery unit 1 has a swirl pot 6 in which the fuel pump 7 is arranged and a flange 11 closing the opening 2 . A fuel pump 7 sucks fuel out of a swirl pot 6 via a prefilter 8 and feeds the fuel via an outlet 9 into a feed line 10 , which leads through a flange 11 to a not shown internal combustion engine of the motor vehicle.

[0020] The flange 11 of the fuel delivery unit 1 and the swirl pot 6 are connected to each other via a support 12 designed as a circular tube. The connection to the flange 11 takes place via the upper region 13 of the pipe 12 , which is pressed into a bushing 14 of the flange 11 . The lower end 15 of the tube 12 is arranged in a receptacle 16 having a circular cross section, so that the tube 12 can slide along the receptacle 16 . The receptacle 16 extends as far as the bottom 17 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com