Braided wire machining apparatus and method for manufacturing end extended braided wire

A processing device and braided wire technology, which is applied in the direction of cable/conductor manufacturing, electrical components, circuits, etc., can solve the problems of scattered and uneven multiple busbars, marshalling shielding wires and poor installation of shielding shells, etc., to prevent scattered, The effect of suppressing skew

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

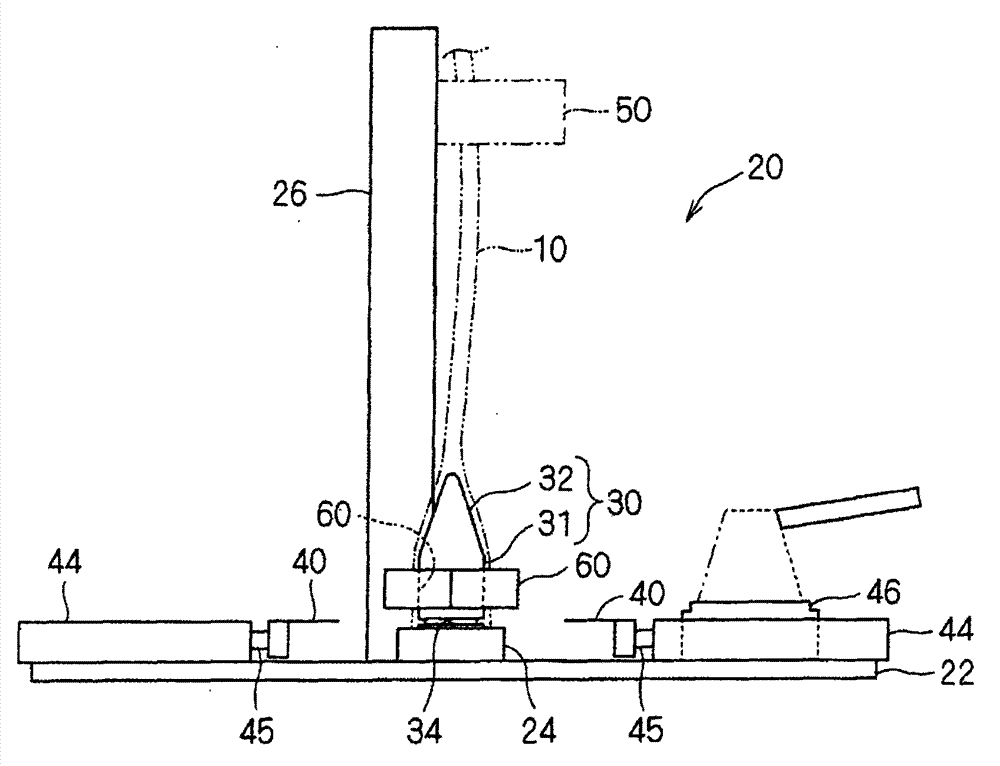

[0046] Next, a braided yarn processing device according to an embodiment will be described.

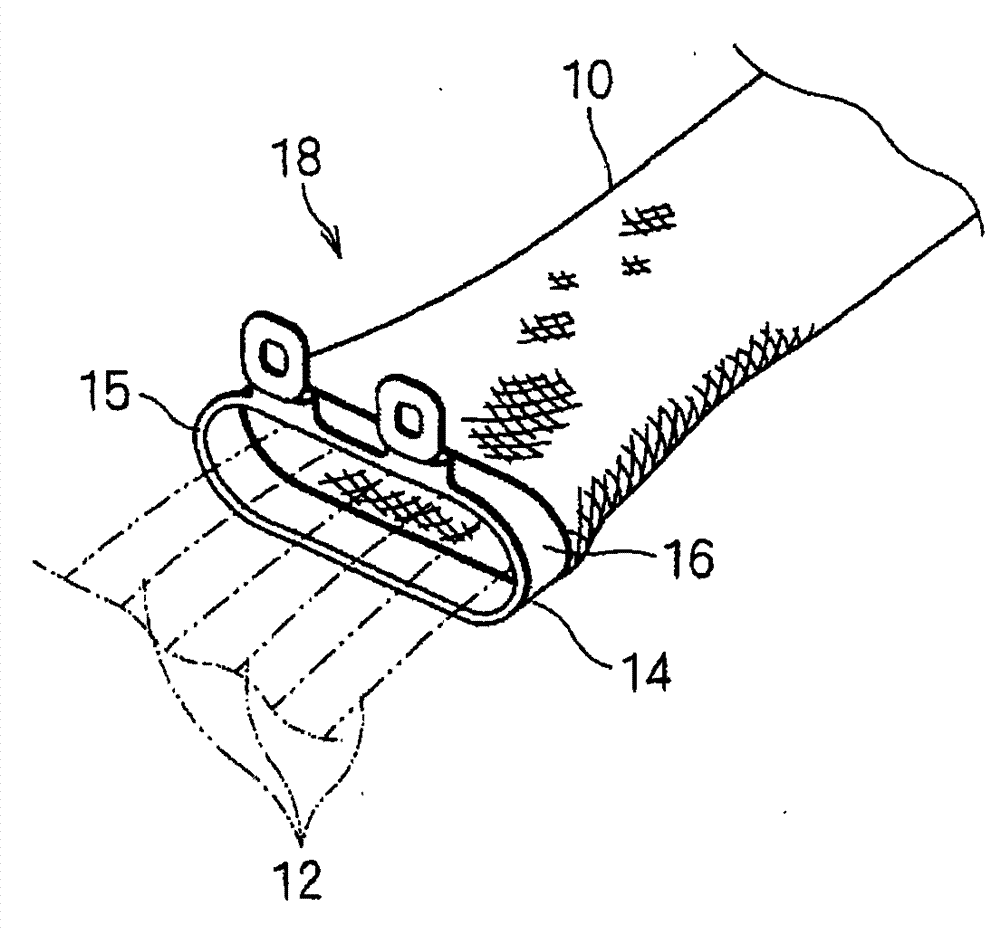

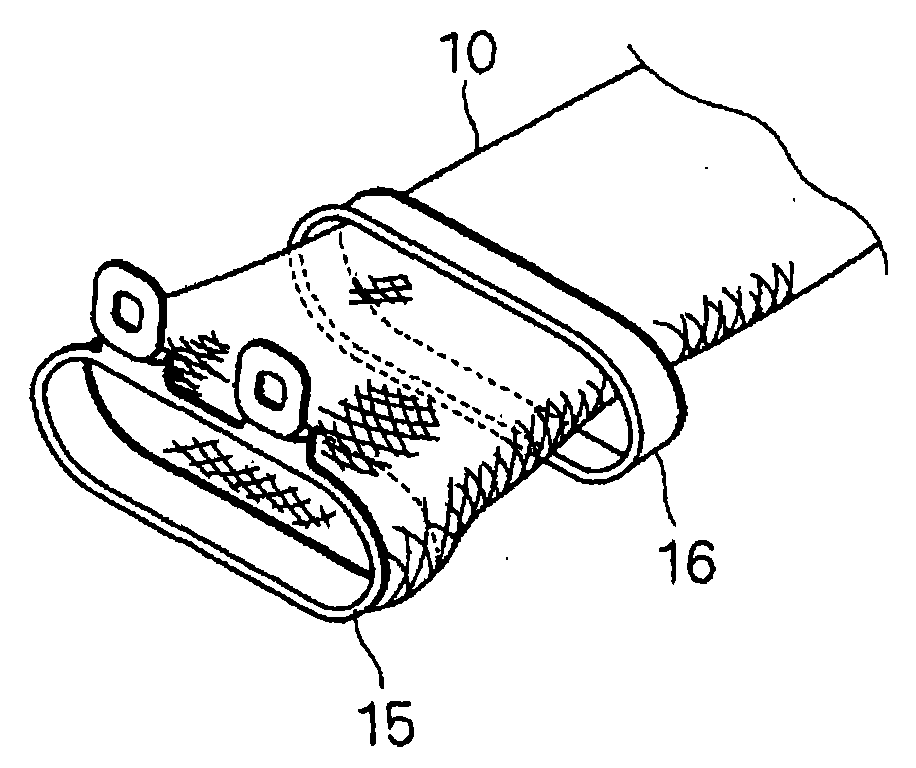

[0047] First, the braided yarn to be processed will be described. figure 1 It is a schematic perspective view showing an example of a shielded wire harness 18 using a braided wire 10, figure 2 It is an explanatory diagram showing one manufacturing process of the shielded wire harness 18 .

[0048] The shielded wire harness 18 is a wiring member applied to electric vehicles such as hybrid vehicles, and has braided wires 10 , electric wires 12 and end fittings 14 . The braided wire 10 has a structure in which fine metal wires are braided to form a mesh cylinder. In addition, the thin metal wire braided to constitute the braided wire 10 may be further formed by twisting a plurality of bus wires (for example, wires with an outer diameter of 0.18 mm). The end fitting 14 has a substantially elongated cylindrical fitting body portion 15 and a crimping fitting 16 . In addition, the end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com