Deformation-compensated high-strength metal sheet shear test block

A technology for sheet metal and shearing specimens, which is applied in the direction of using a stable shear force to test the strength of materials, and using a stable tension/pressure test to test the strength of materials, etc. , to achieve the effect of avoiding initial surface damage, simple and convenient use, and avoiding mechanical processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention provides a high-strength sheet metal shear test piece with deformation compensation. The present invention will be further described below in conjunction with the description of the drawings and specific implementation methods.

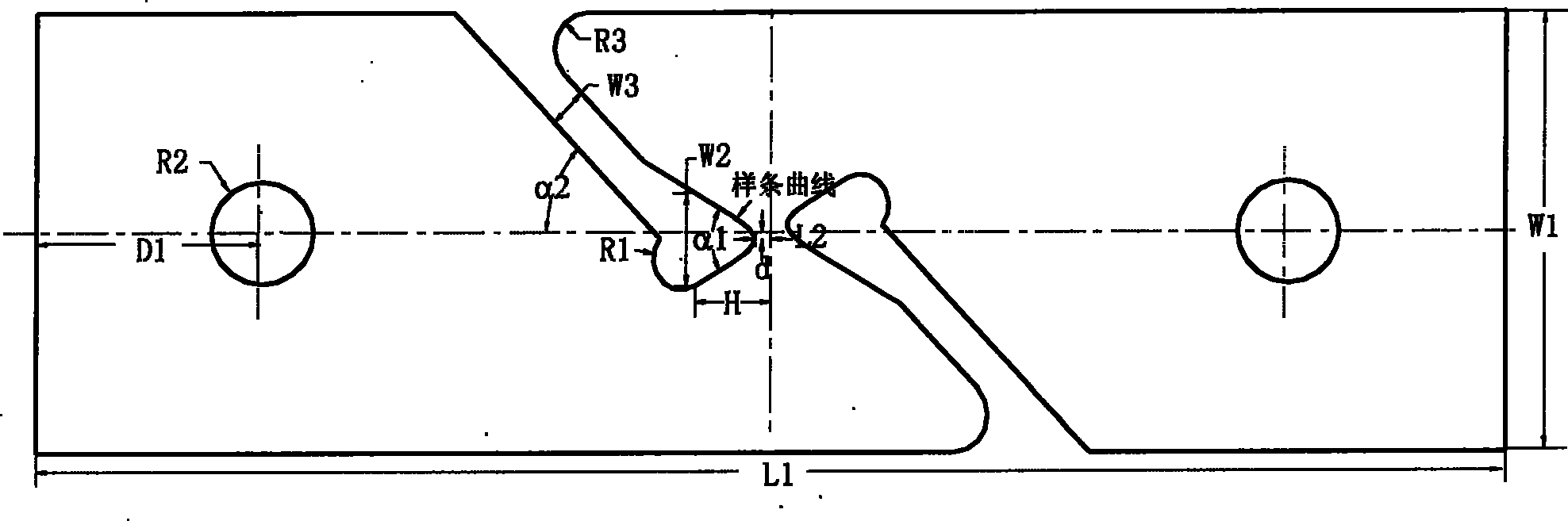

[0014] figure 1 It is a top view of the test piece of the present invention; the material of the test piece is duplex steel, and the outer contour is rectangular, wherein the length of the major axis L1=220mm, the length of the minor axis W1=60mm, and the thickness of the test piece t=2mm; Two circular holes are arranged symmetrically at both ends of a long central axis of the test piece, which are used to load the fixture of the tensile testing machine. The distance between the center of the circular hole and the side parallel to the short axis is D1=33.36mm, and the hole radius is R2 = 7mm; in the middle area of the test piece, set a heart-shaped opening with two pointed tops facing each other. The width of the heart-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com