Precast spliced concrete slab wall body

A technology for prefabricated concrete slabs and concrete slabs, which is applied to walls, building materials, building components, etc., can solve the problems of difficult popularization of pouring methods, reduced wall practicability, and difficulty in meeting the requirements of mounting capacity and durability. The process saves time and effort, reduces requirements, and has the effect of low average density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

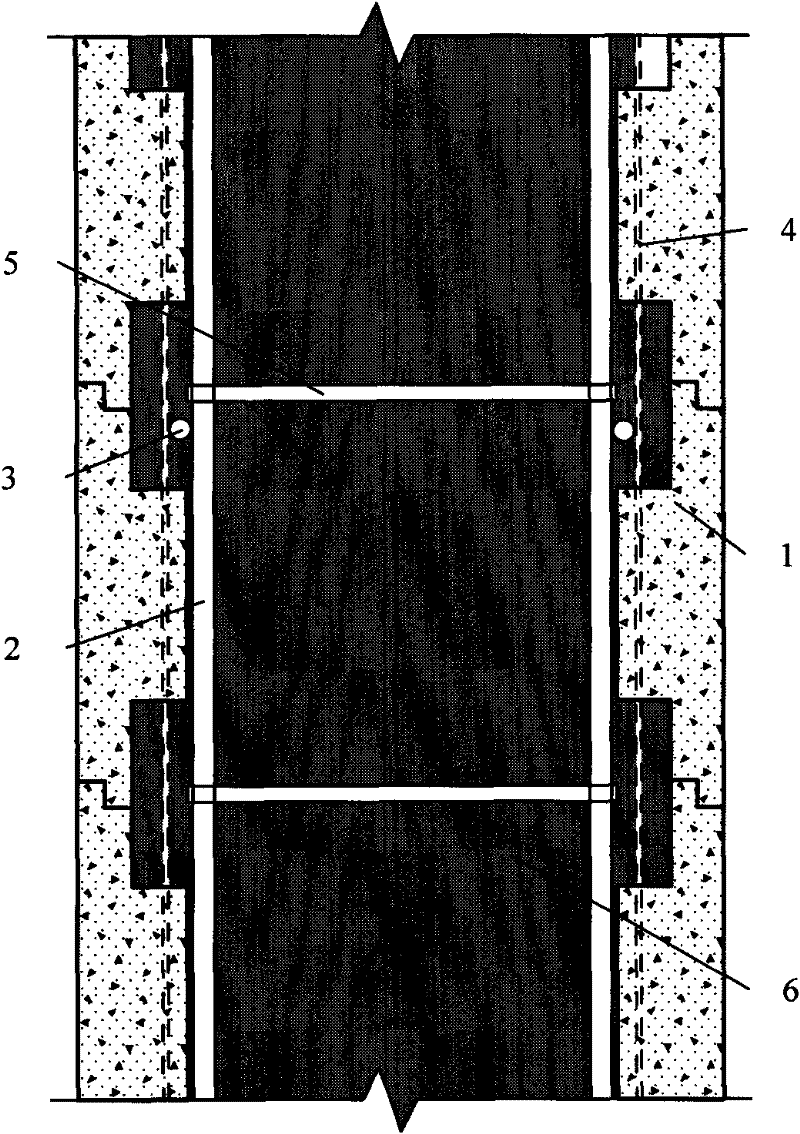

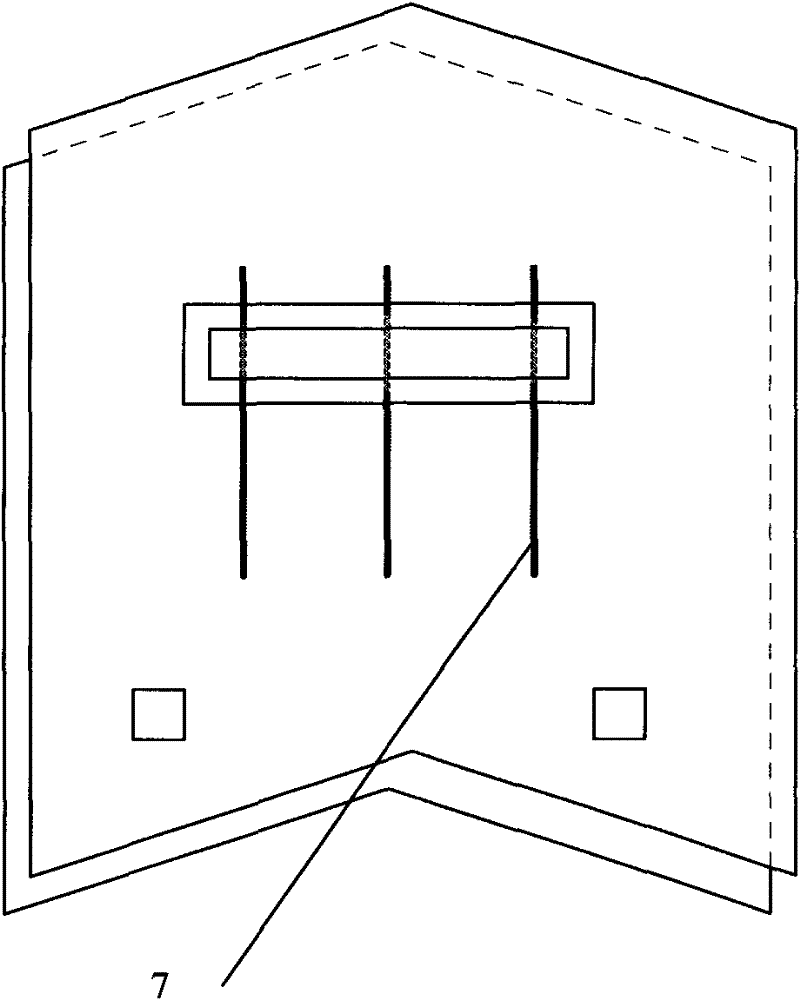

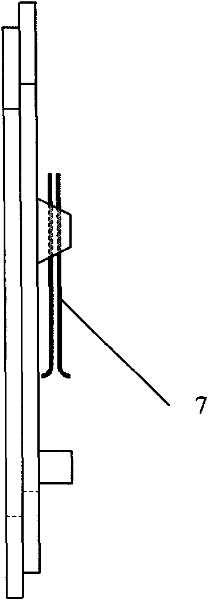

[0027] A prefabricated spliced concrete slab wall body, the wall body includes a steel skeleton, inner and outer wall panels and a lightweight concrete layer in the middle. The inner and outer walls are spliced by prefabricated concrete slabs 1. The precast concrete slabs 1 use fiber-reinforced concrete as the raw material, adopt a non-rectangular geometric appearance, have rough inner surfaces, and have overlapping eaves at the ends for easy splicing. The poured lightweight concrete layer is provided with a reinforcement skeleton in the middle, and the reinforcement skeleton is arranged along the entire length of the wall, and is connected with the load-bearing members at the edge of the wall. Horizontal steel wires 4 are arranged at regular intervals along the height direction on the reinforcement skeleton. The inner surface of the precast concrete slab 1 is provided with a prism-like protrusion, and the positioning steel wire 7 parallel to the direction of the slab surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com