Electric frost prevention observation window

An observation window and anti-frost technology, applied in the field of laboratory observation windows, can solve the problems of poor sealing effect, condensation and frost of the anti-cold bridge sealing observation window, and achieve good sealing effect, avoid water vapor, and accurately control temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

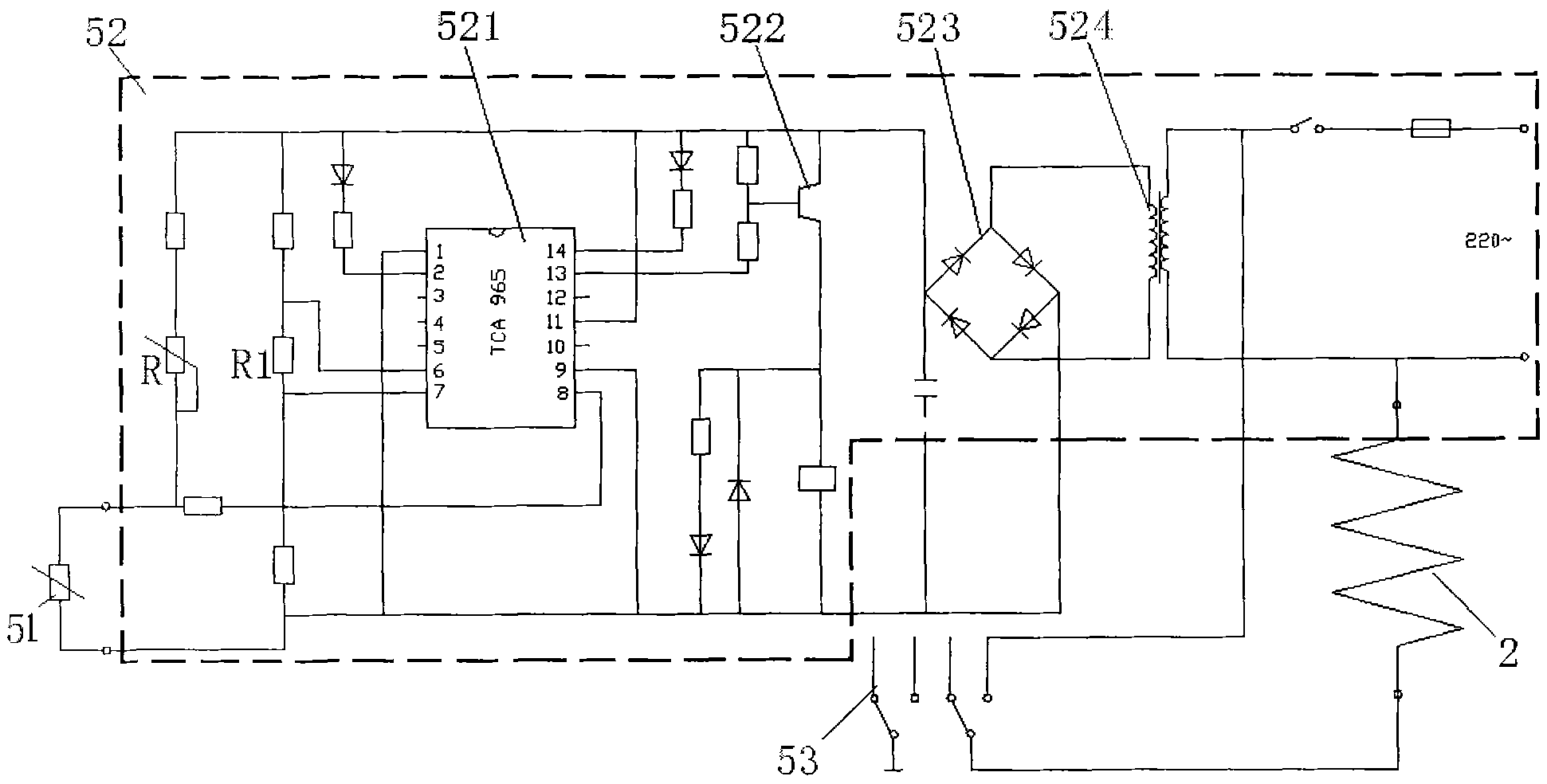

[0019] Such as figure 1 , figure 2 As shown, the present invention includes an observation window 1, a transparent heating film 2, a flange 3, a sealing ring 4 and a heating control circuit 5, wherein the observation window 1 is arranged on the wall of the laboratory through the flange 3 , and the periphery of the observation window 1 is sealed with a sealing ring 4 to prevent convection between the laboratory and the outside air. The heating film 2 is a transparent conductive coating, which is attached to the inner surface of the observation window 1. In this embodiment, the heating film 2 is Sn-doped In with a thickness of 0.55 μm. 2 o 3 (tin-doped indium trioxide). The heating film 2 is electrically connected to the heating control circuit 5 through wires, and the heating control circuit 5 compares the collected actual temperature with the set...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com