Three-dimensional multidirectional-sensitive micromechanical inertial electrical switch

A micro-mechanical, multi-directional technology, applied in electrical switches, circuits, electrical components, etc., can solve problems such as short time, poor contact effect, and high stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

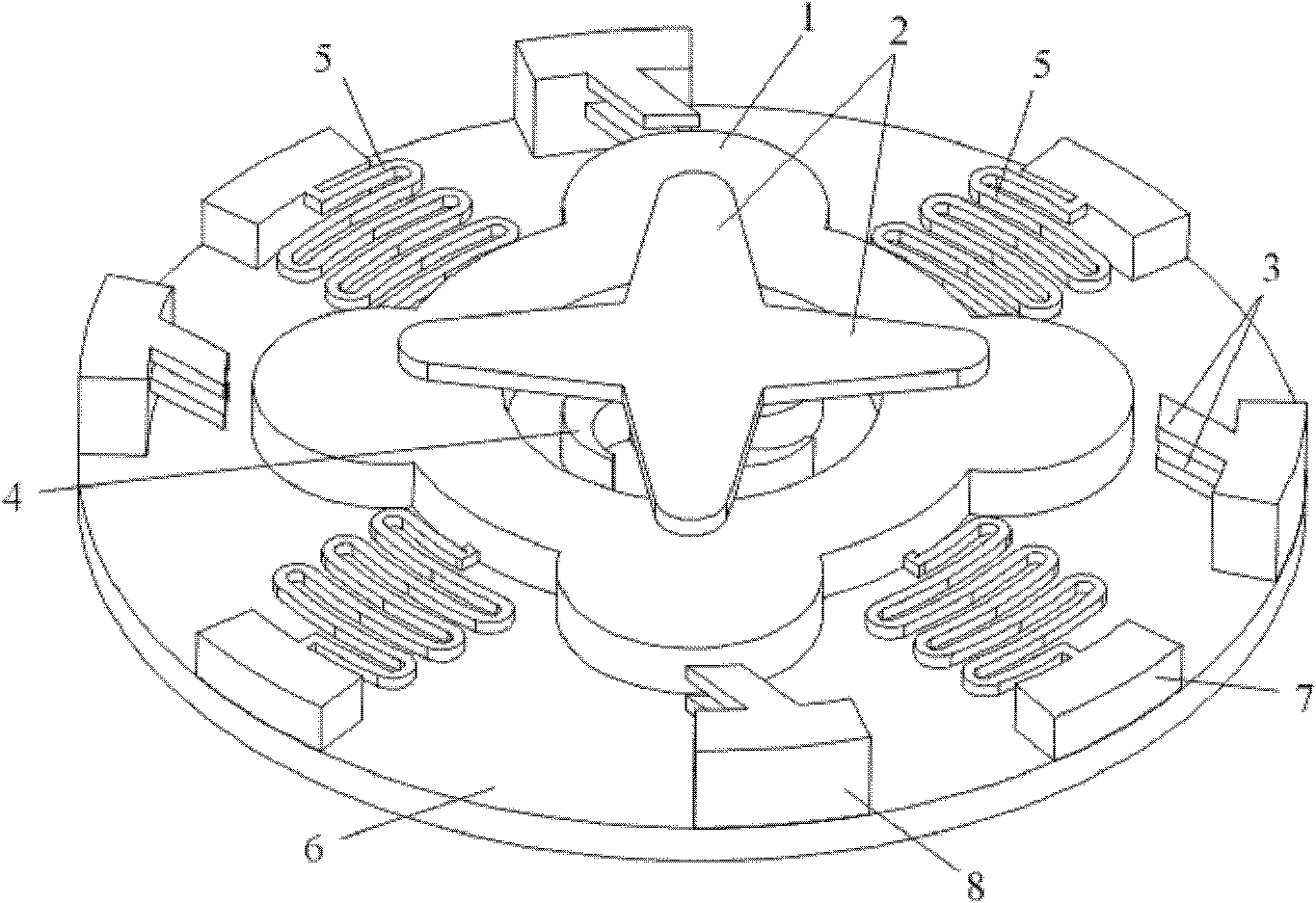

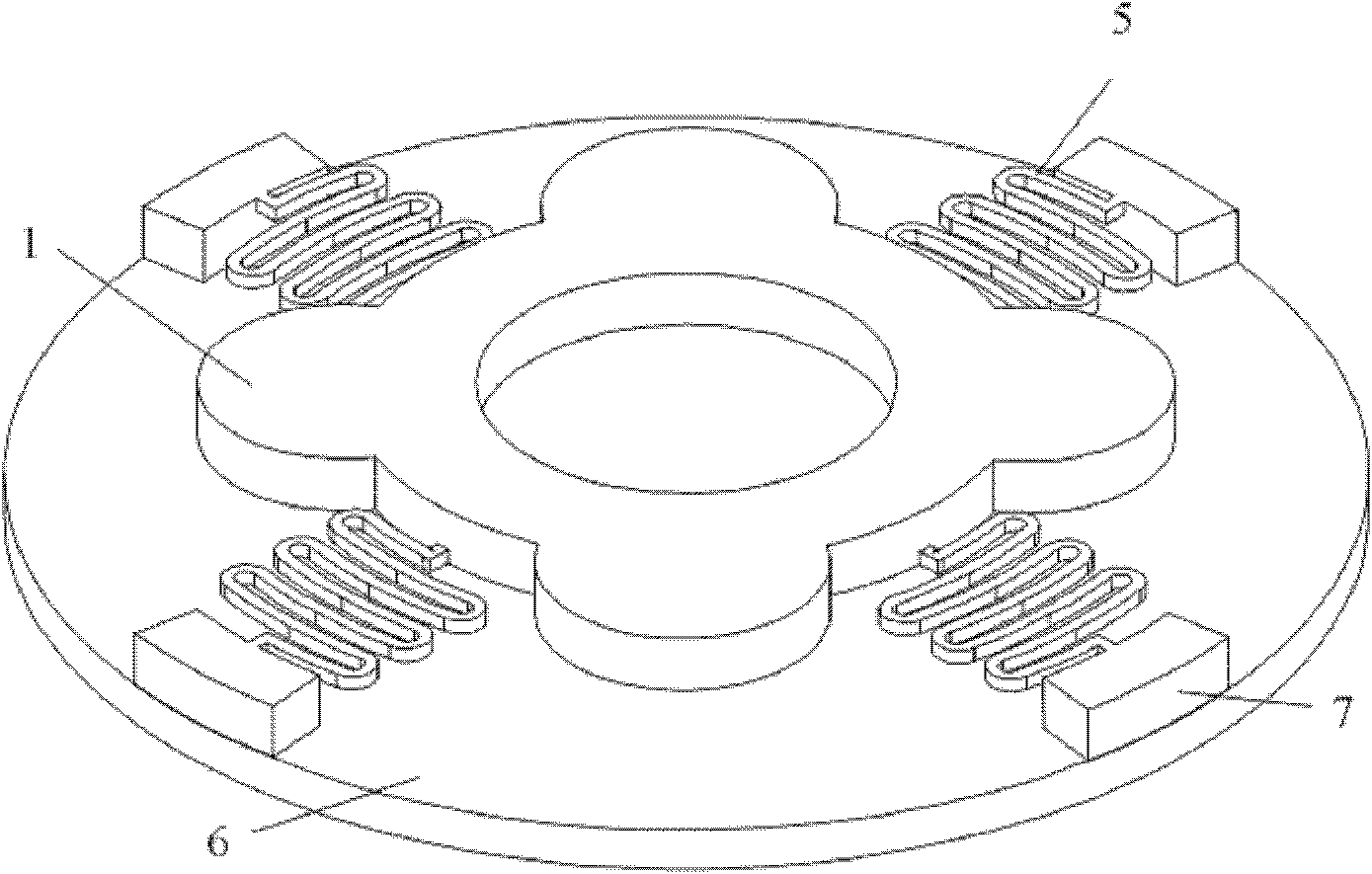

[0028] Such as figure 1 As shown, this embodiment includes: mass electrode 1, cantilever beam vertical fixed electrode 2, cantilever beam horizontal fixed electrode 3, spiral horizontal fixed electrode 4, serpentine spring 5, insulating substrate 6, spring support seat 7, cantilever Beam supporting base 8, spiral fixed electrode supporting base 9 and vertical fixed electrode supporting base 10, wherein: mass electrode 1 is connected with one end of four sets of serpentine springs 5 respectively, and the other ends of four sets of serpentine springs 5 are connected with the spring supporting base 7 phases are connected and the mass electrode 1 is suspended above the insulating substrate 6 and 10 to 50 microns below the cantilever beam vertical fixed electrode 2, and the spring support seat 7 and the cantilever beam support seat 8 are respectively fixed on the insulating substrate 6 and Located around the mass electrode 1, the distance between the cantilever beam support bas...

Embodiment 2

[0044] Such as Figure 5 As shown, in this embodiment, the horizontal fixed electrode 3 of the cantilever beam with a single-layer structure is arranged on the periphery of the mass electrode 1. The three-dimensional multi-directional sensitive micromechanical inertial electrical switch is the same, and except for the fixed electrode of the horizontal cantilever beam, the shape and size of the other components are the same as those in Embodiment 1.

Embodiment 3

[0046] Such as Figure 6 As shown, in this embodiment, a cantilever beam with a cylindrical plane with holes is used to vertically fix the electrode 2. The radius of the cylindrical plane of the vertical fixed electrode 2 is 500-1000 microns, and the thickness is 20-50 microns. The through hole 11 has a radius of 10 to 50 microns, uniformly distributed on the cylinder, the distribution pitch is 50 to 100 microns, and the rest of the features of the micromechanical inertial electrical switch are similar to those of Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com