Fiber distributor

A technology of sample distribution device and fiber, which is applied in the preparation of test samples, etc. It can solve the problems of difficult cleaning of the cutter head, influence on sample quality, and uneven sample distribution, so as to achieve short sample distribution time, avoid secondary pollution, uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below with reference to the drawings and embodiments:

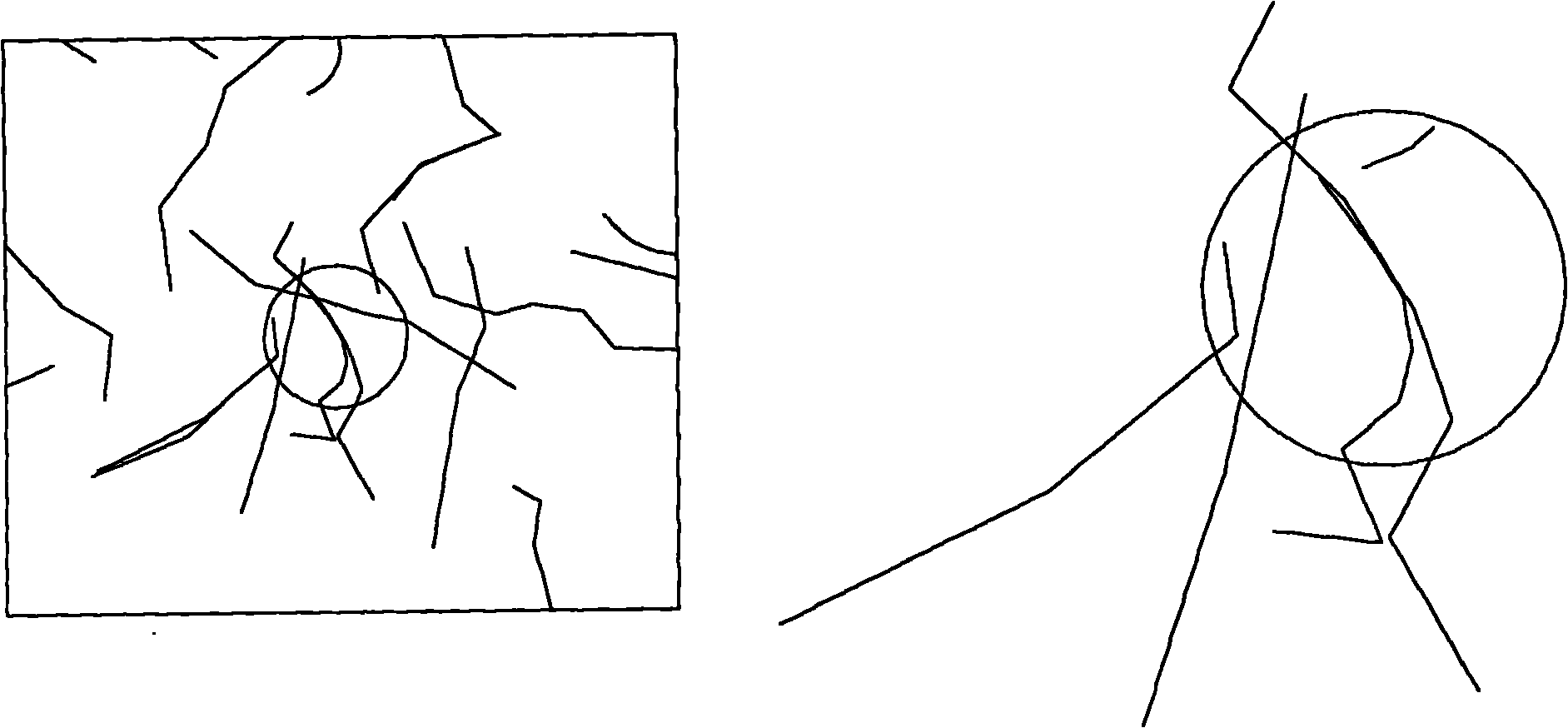

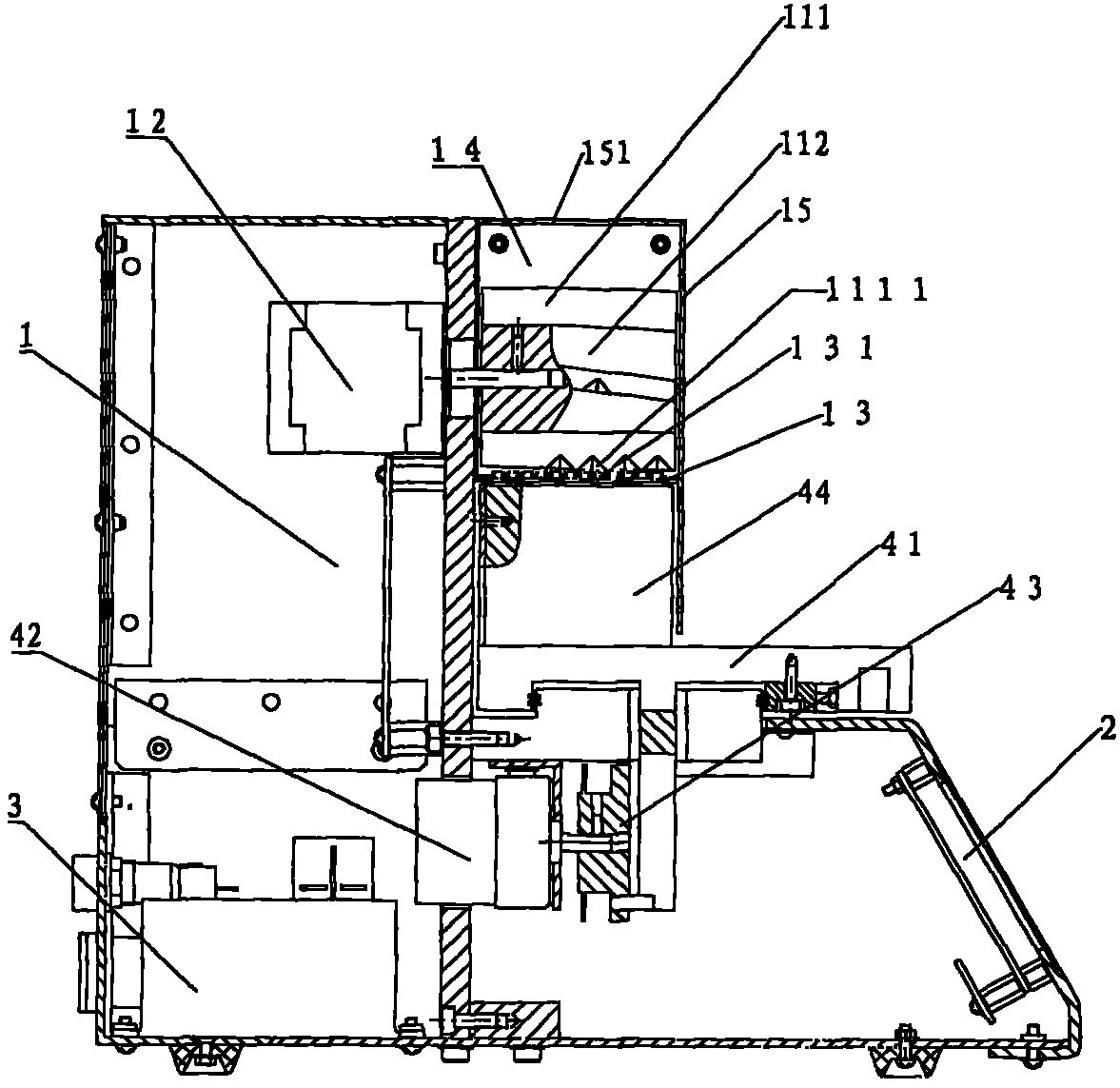

[0028] Before measuring the fiber diameter, the fiber must be evenly distributed on the glass slide, and then the glass slide is placed under a microscope for inspection. In order to enable the fibers to be quickly and evenly distributed on the glass slide, the fiber patterning device of the present invention is composed of a fiber dispersing and spreading device 1, a control circuit 2, a power source 3 and a reciprocating translation device 4. The reciprocating translation device 4 of the present invention is located below the fiber dispersing and spreading device 1, and the range of its reciprocating translation is matched with the fiber dispersing and spreading device 1. The reciprocating translation device 4 is composed of a reciprocating translation mechanism 41, a drive motor 42, a power conversion mechanism 43 and a limit frame 44. The driving motor 42 is drivi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com