Tunnel kiln smoke-gas heat exchanging dust-removal emission reduction device

A flue gas heat exchange and tunnel kiln technology, which is used in waste heat treatment, lighting and heating equipment, furnaces, etc., can solve the problems of difficulty in dredging, the flue gas heat exchange device cannot operate normally, and the flue is blocked.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

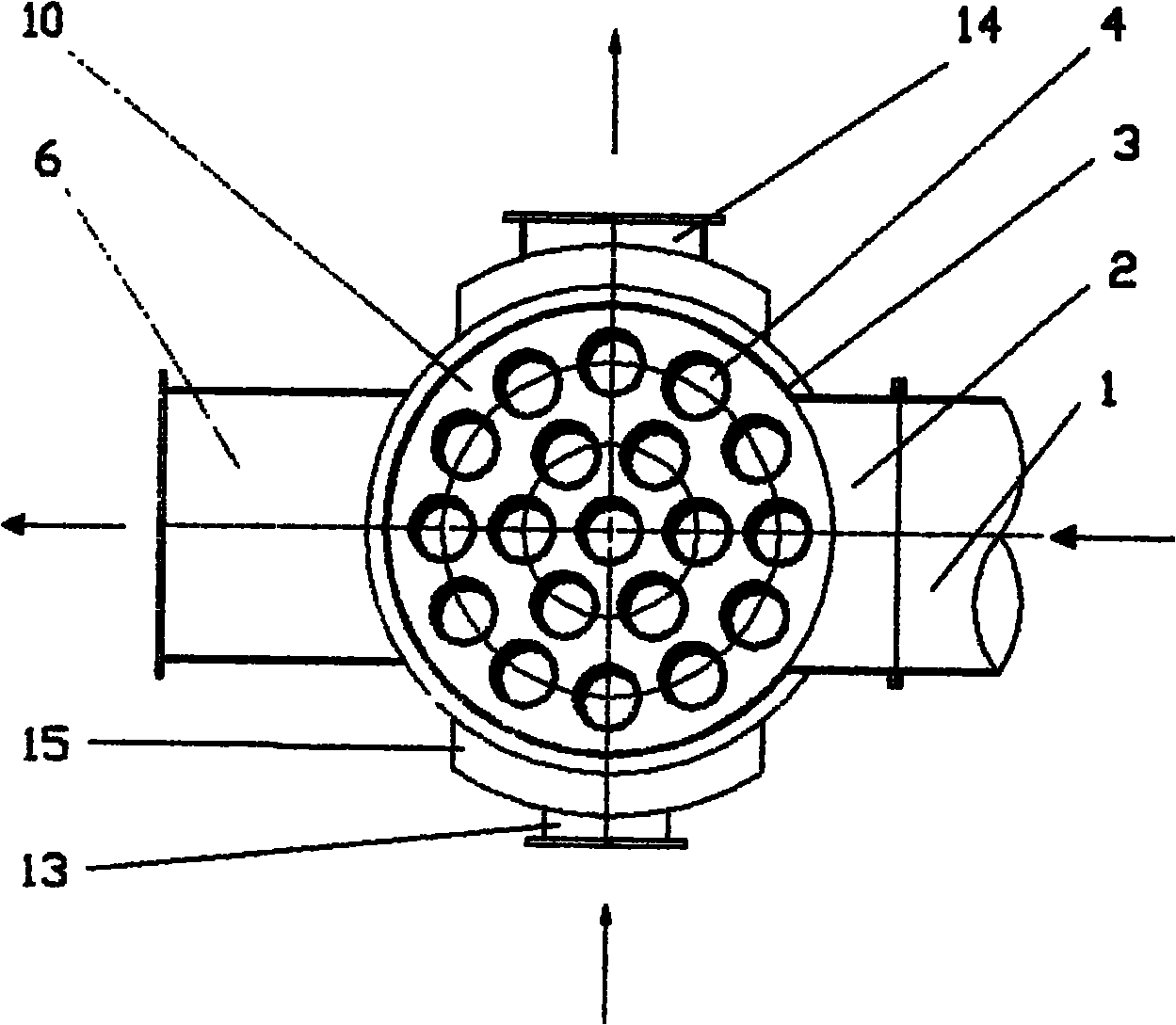

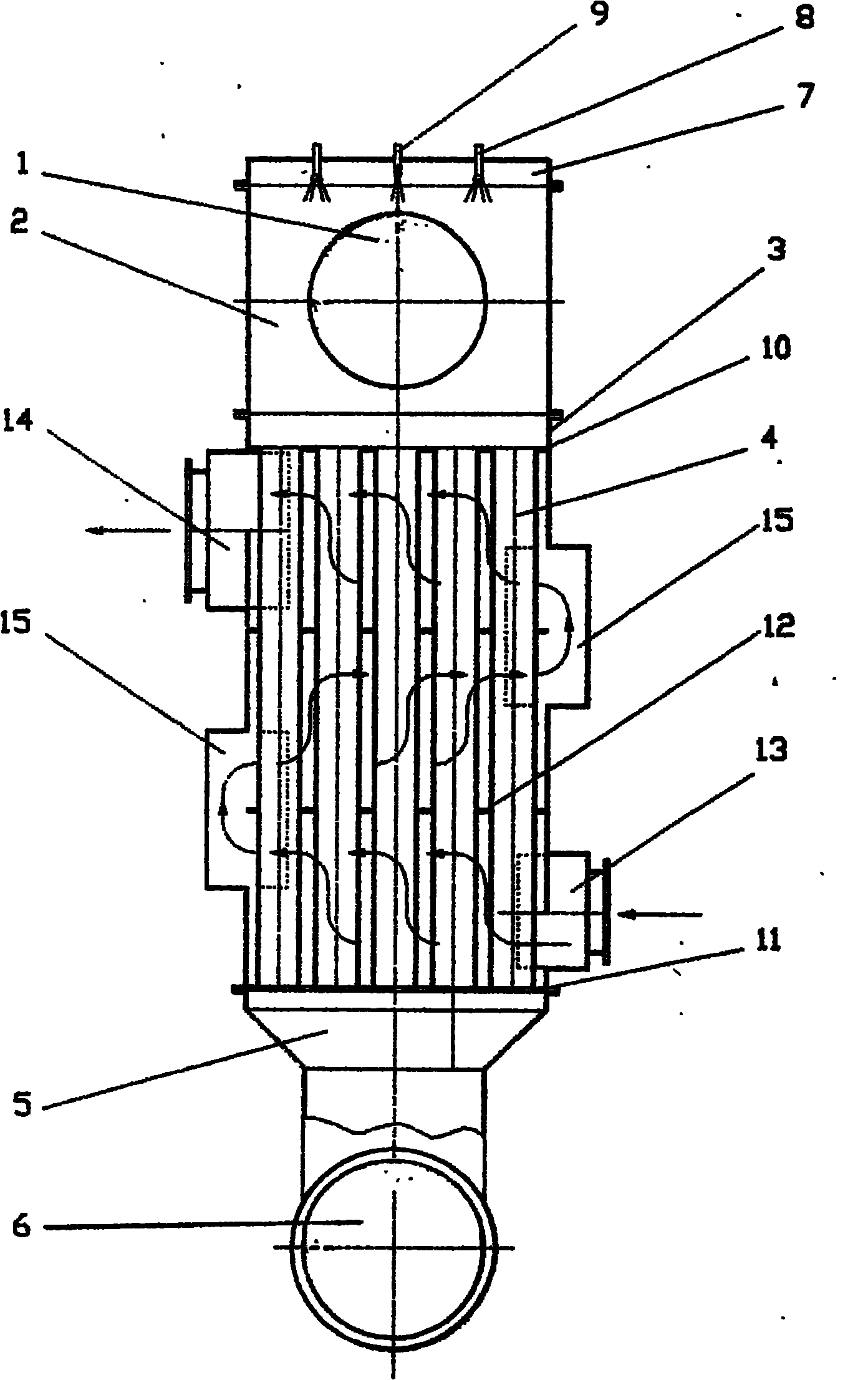

[0012] The tunnel kiln flue gas heat exchange dust removal and emission reduction device of the present invention is realized in this way, which will be described in detail below in conjunction with the accompanying drawings. See figure 1 , figure 2 , image 3 , The tunnel kiln flue gas heat exchange, dust removal and emission reduction device is arranged between the smoke exhaust main pipe 1 of the tunnel kiln subtropical kiln roof and the suction elbow 6 of the ground smoke exhaust machine. The main body of the tunnel kiln flue gas heat exchange, dust removal and emission reduction device is a vertical circular shell straight tube convection heat exchanger. Straight tubes 4 are arranged on the concentric circle inside the vertical circular shell 3, and the upper ends of the straight tubes 4 are fixed on the upper tube plate 10. On the top, the lower end of the straight pipe 4 is fixed on the lower tube plate 11, and a guide partition 12 is provided in the middle of the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com