Optimal design method for valve cam profile

A technology of optimized design and gas distribution cam, which is applied in calculation, special data processing applications, instruments, etc., and can solve problems such as flying off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

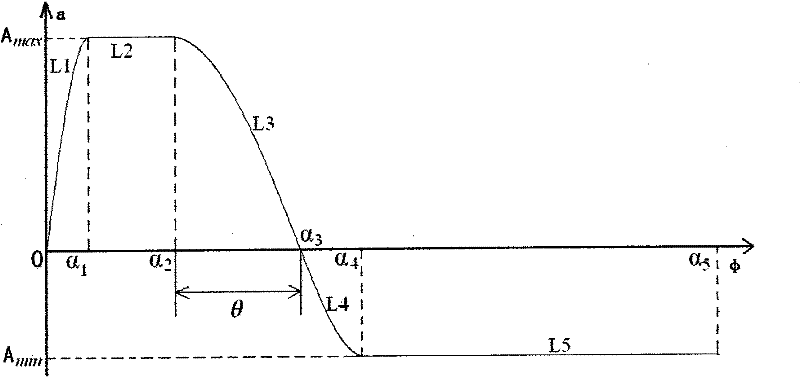

[0016] Here, the 1 / 4 wave sine is taken as an example to illustrate the design method, and the design of ellipse and high-order square line mathematical formulas can be obtained in the same way. figure 2 is the tappet acceleration curve of 1 / 4 wave sine, that is, where L 1 , L 3 , L 4 It is a 1 / 4 wave trigonometric function curve;

[0017] Depend on figure 2 The acceleration curve diagram of can give the acceleration formula, as shown in Mathematical Formula 1:

[0018] [mathematical formula 1]

[0019] a = a 1 = A max sin ( πα 2 α 1 ) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com