Screen printing machine

A screen printing machine, tension control technology, applied in screen printing machine, printing machine, rotary printing machine and other directions, can solve the problems of product printing quality impact, product scrapping and other problems, achieve a high degree of automation, improved quality, guarantee The effect of print quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

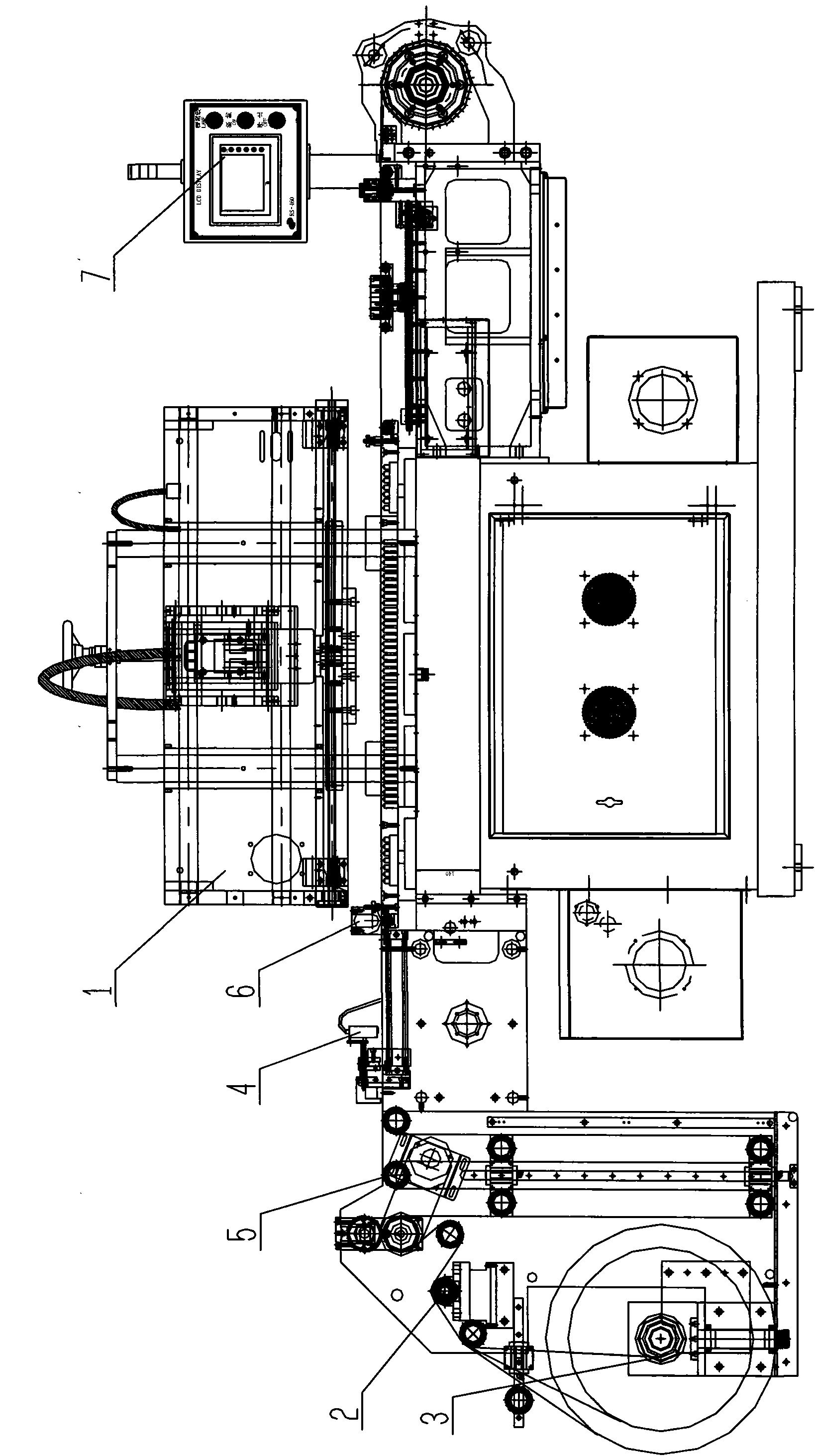

[0011] Such as figure 1 As shown, a schematic diagram of the structural composition of the screen printing machine of the present invention is provided. A tension control system, an edge system and a dust removal wheel are sequentially installed at the feed end of the screen printing machine. The tension control system includes a tension detector 2 and a magnetic powder Type clutch 3, through the control system 7 of the whole machine, the magnetic powder clutch can control the feeding speed according to the feeding tension measured by the tension detector 2, so as to keep the material taut to a certain extent, thereby avoiding the occurrence of wrinkling The edge-to-edge system includes electric eyes 4 and deviation correction devices 5. During the feeding process, the complete machine control system 7 receives the displacement offset signal of the edge of the material monitored by the electric eyes in real time, controls the deviation correction device 5 to act accordingly, an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap