Automatic production line for automobile chains

An automatic production line and automobile chain technology, applied in the direction of metal chains, etc., can solve the problems of automatic assembly of automobile chain valve plates, automatic link riveting heads, and automatic distinction between qualified products and waste products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

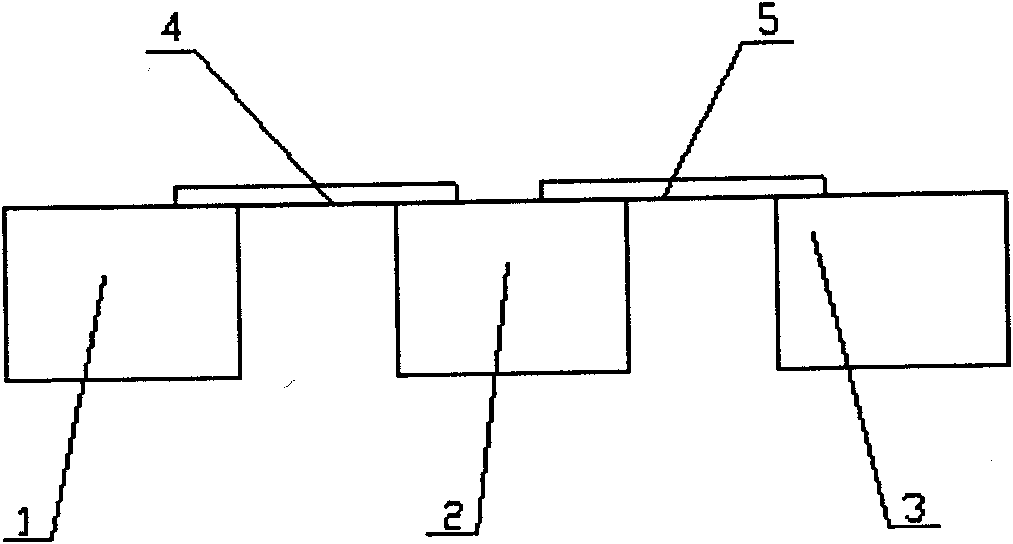

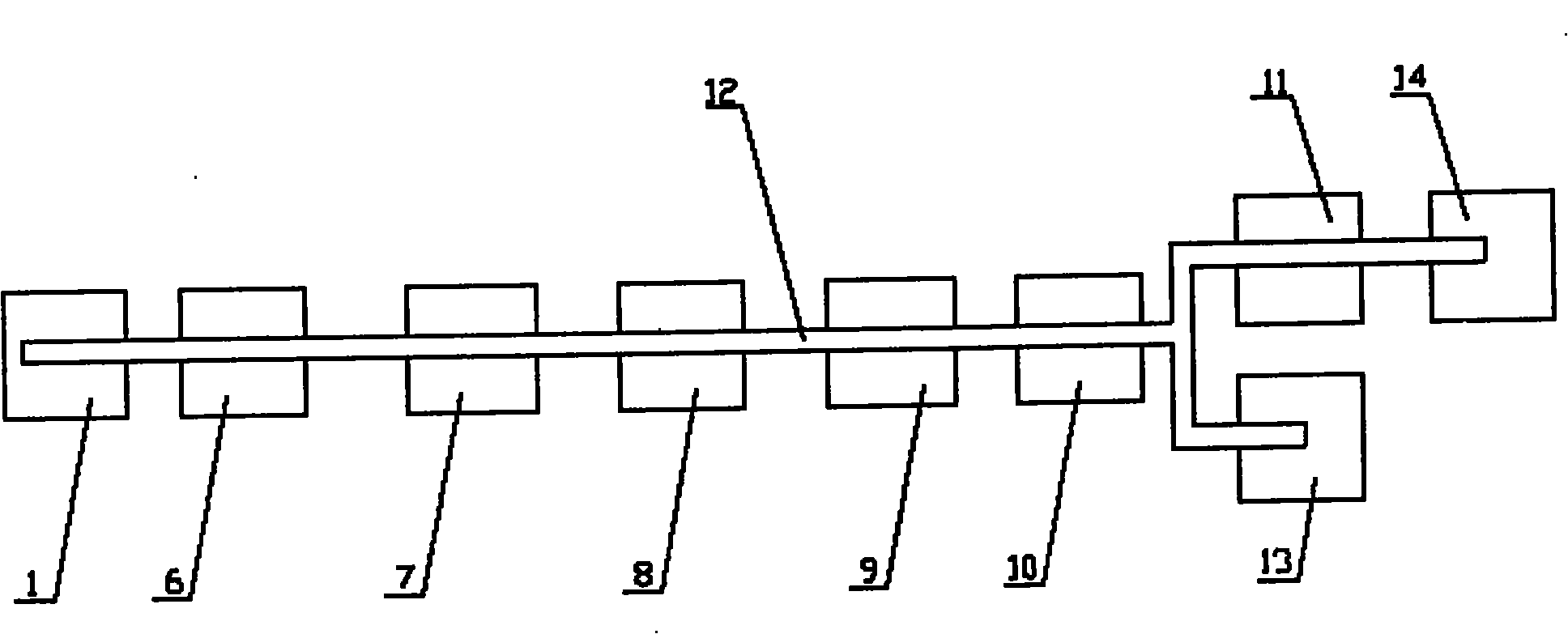

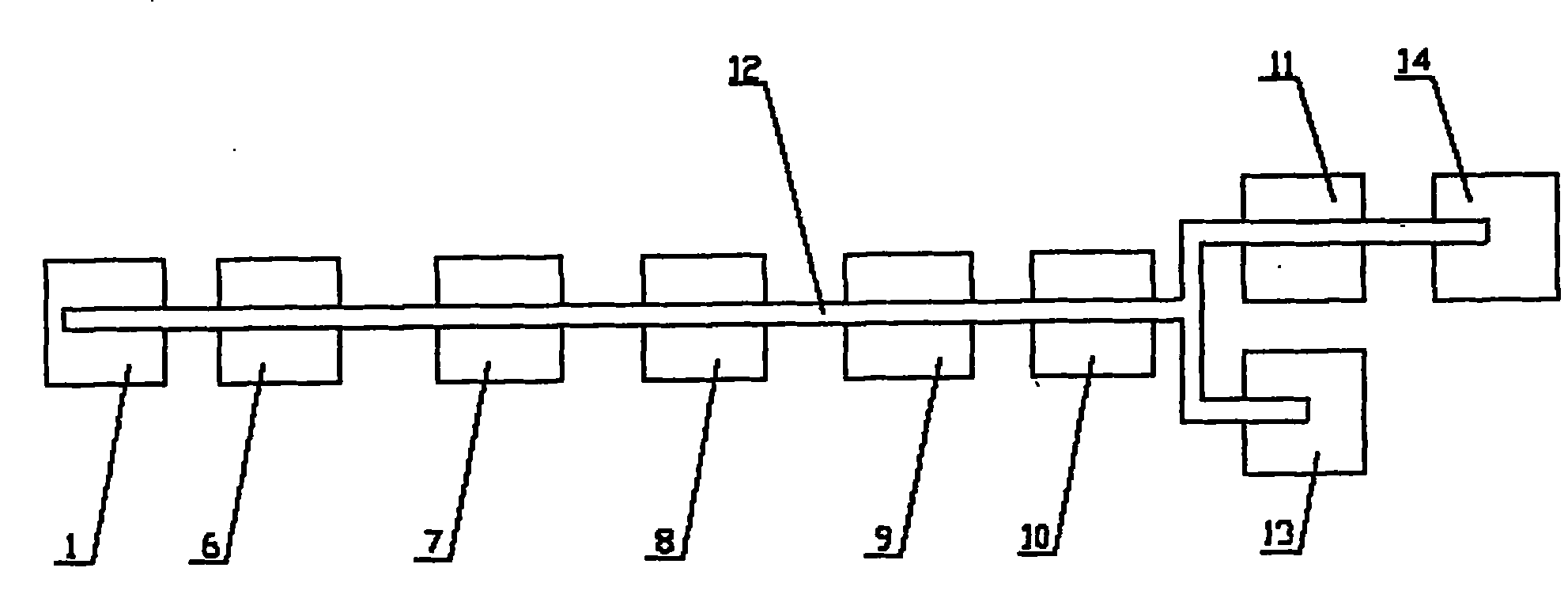

[0009] Such as figure 2 As shown, its structure is a chain high-speed assembly machine 1, a pre-tensioning running machine 6, a joint dismantling machine 7, a valve plate assembly machine 8, a riveting head machine 9, and a special inspection machine 10 connected in series through a guide rail 12. At the same time, the guide rail 12 is also connected in series with ring joint riveting head machine 11 and finished product box 14 on the one hand, and guide rail 12 is also connected in series with waste product box 13 on the other hand. Raw materials such as inner sheet, lower outer sheet, shaft pin, upper outer sheet, etc. are assembled by chain high-speed assembly machine 1 to form a chain. A circuitous guide rail 12 is provided between the sprockets of the pre-tensioning running-in machine. Driven by the motor of the pre-drawing running-in machine, the chain realizes the pre-tightening effect, and simultaneously realizes the running-in function in the circuitous guide rail. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com